Mist-inhibiting rust remover and preparation method thereof

A rust agent and fog removal technology, applied in the field of fog suppression and rust remover and its preparation, can solve the problems of increasing processing cost, declining metal mechanical properties, affecting steel strength, etc., so as to avoid product quality inconsistency and improve transportation safety. , the effect of avoiding corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

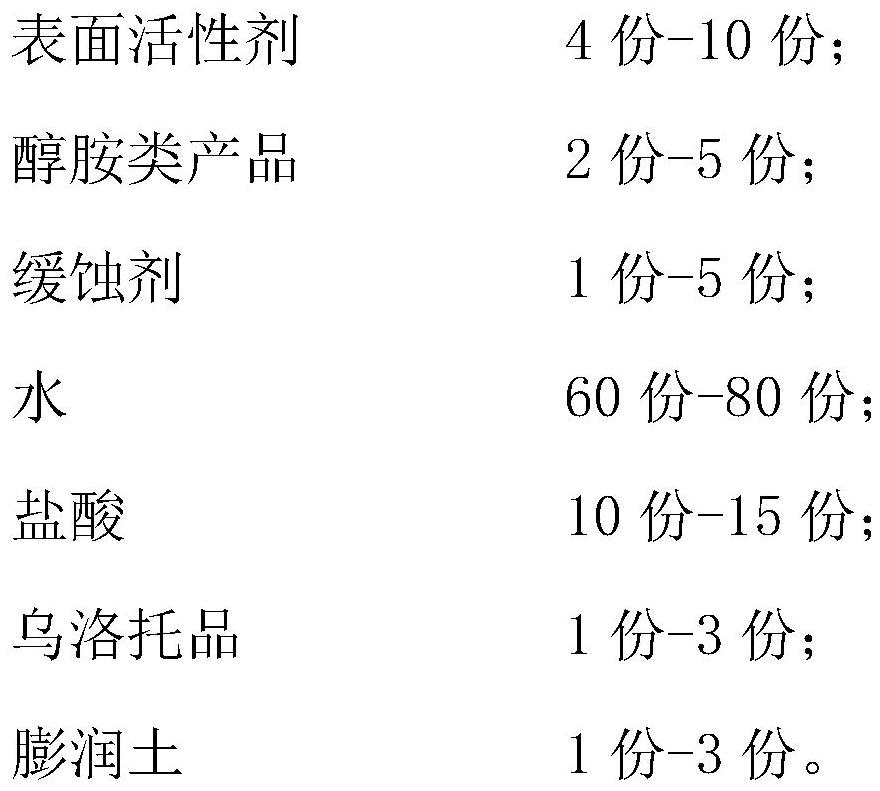

Method used

Image

Examples

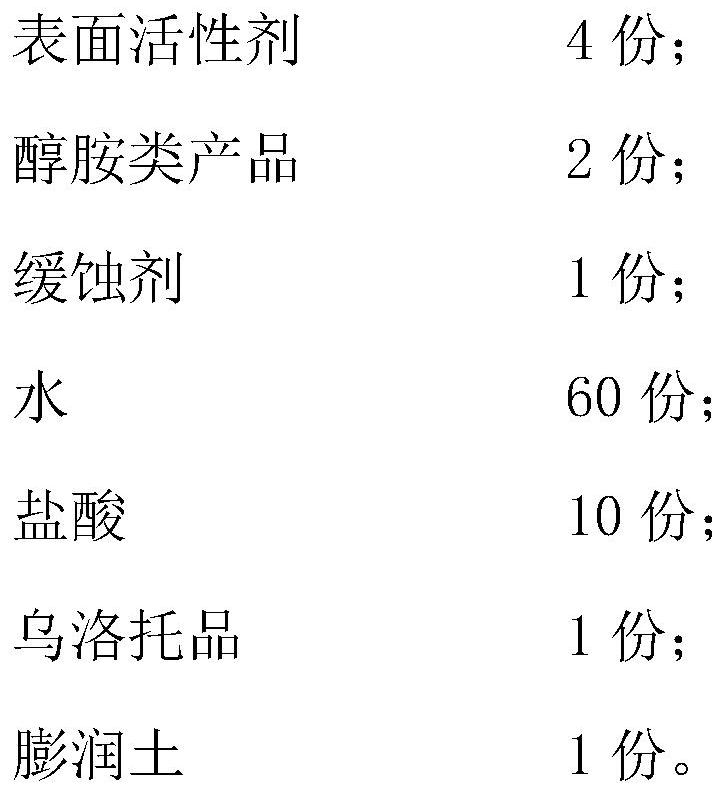

Embodiment 1

[0029] Step 1, raw material pretreatment, put the purchased enough raw materials into the grinder for grinding respectively, grind the agglomerates therein, then pass the raw materials through a 150-mesh sieve, and store the raw materials under the sieve for later use;

[0030] Step 2, mixing processing: Weigh 4 parts of surfactant, 2 parts of alcohol amine products, 1 part of corrosion inhibitor, 60 parts of water, 10 parts of hydrochloric acid, 1 part of urotropine and 1 part The bentonite is poured into the inside of the stirring device together, the stirring speed is set to 100rpm, and the stirring time is set to 5 minutes to obtain the fog-suppressing and rust-removing agent;

[0031] Step 3: Sampling, testing, packaging and warehousing: Sampling the finished product of the anti-fog and rust remover, stirring the sample again before testing, and packaging and warehousing after passing the test.

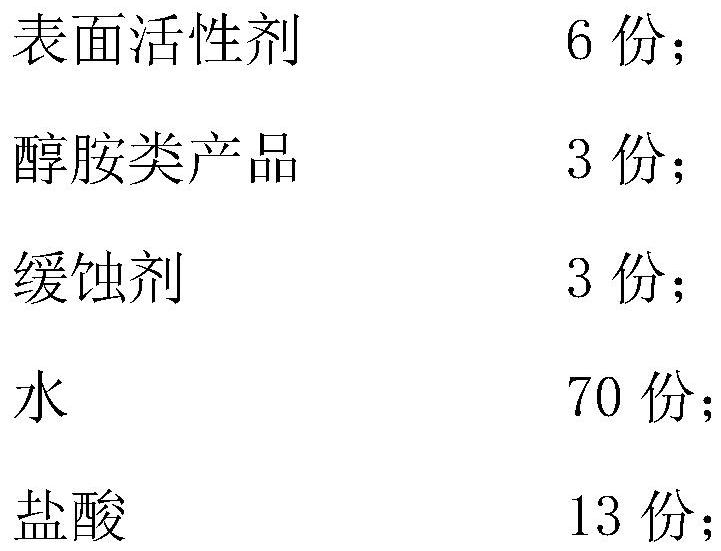

Embodiment 2

[0033] Step 1, raw material pretreatment, put the purchased enough raw materials into the grinder for grinding respectively, grind the agglomerates therein, then pass the raw materials through a 150-mesh sieve, and store the raw materials under the sieve for later use;

[0034] Step 2, mixing processing: Weigh 6 parts of surfactants, 3 parts of alcohol amine products, 3 parts of corrosion inhibitors, 70 parts of water, 13 parts of hydrochloric acid, 2 parts of urotropine and 2 parts of Bentonite is poured into the inside of the stirring device together, the stirring speed is set to 100rpm, and the stirring time is set to 5 minutes to obtain the anti-fog and rust remover;

[0035] Step 3: Sampling, testing, packaging and warehousing: Sampling the finished product of the anti-fog and rust remover, stirring the sample again before testing, and packaging and warehousing after passing the test.

Embodiment 3

[0037] Step 1, raw material pretreatment, put the purchased enough raw materials into the grinder for grinding respectively, grind the agglomerates therein, then pass the raw materials through a 150-mesh sieve, and store the raw materials under the sieve for later use;

[0038] Step 2, mixing processing: Weigh 10 parts of surfactants, 5 parts of alcohol amine products, 5 parts of corrosion inhibitors, 80 parts of water, 15 parts of hydrochloric acid, 3 parts of urotropine and 3 parts of bentonite, together Pour into the inside of the stirring device, set the stirring speed to 100rpm, and set the stirring time to 5 minutes to obtain the anti-fog and rust remover;

[0039] Step 3: Sampling, testing, packaging and warehousing: Sampling the finished product of the anti-fog and rust remover, stirring the sample again before testing, and packaging and warehousing after passing the test.

[0040] In the present invention, in step 1, different raw materials are put into different grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com