Low-temperature, high-strength high-toughness high-entropy alloy and machining method thereof

A high-entropy alloy and high-toughness technology, applied in low-temperature, high-strength, high-toughness high-entropy alloys and their processing fields, can solve problems such as reducing plasticity and limiting the application of high-entropy alloys, and achieve improved low-temperature performance, reasonable strength and plasticity. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

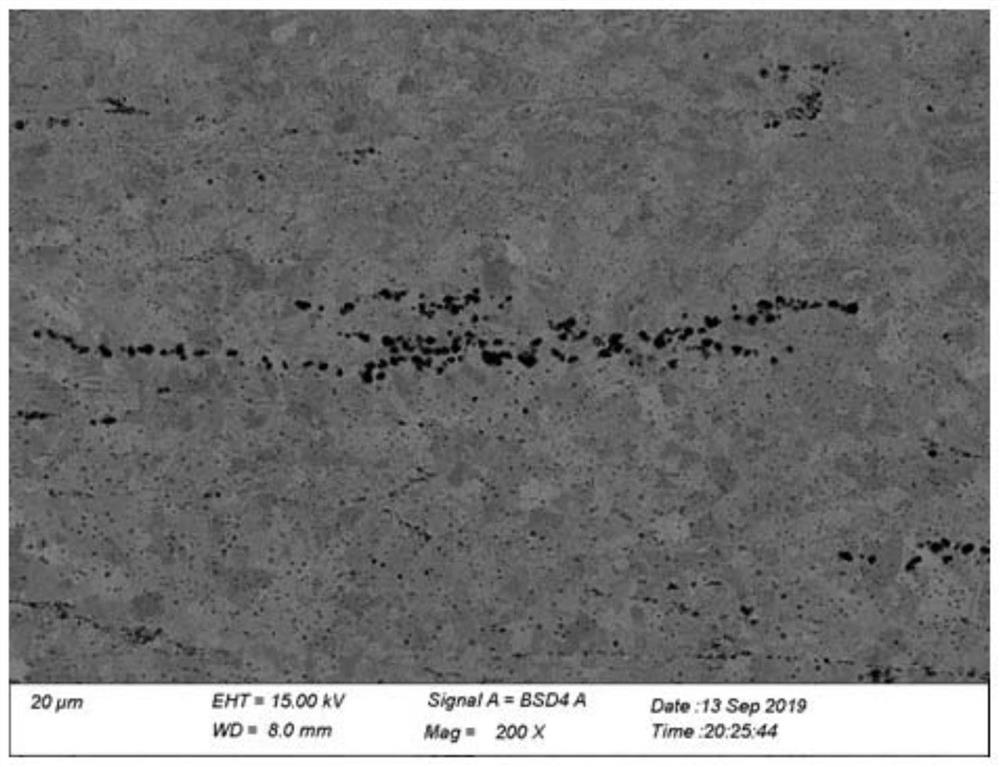

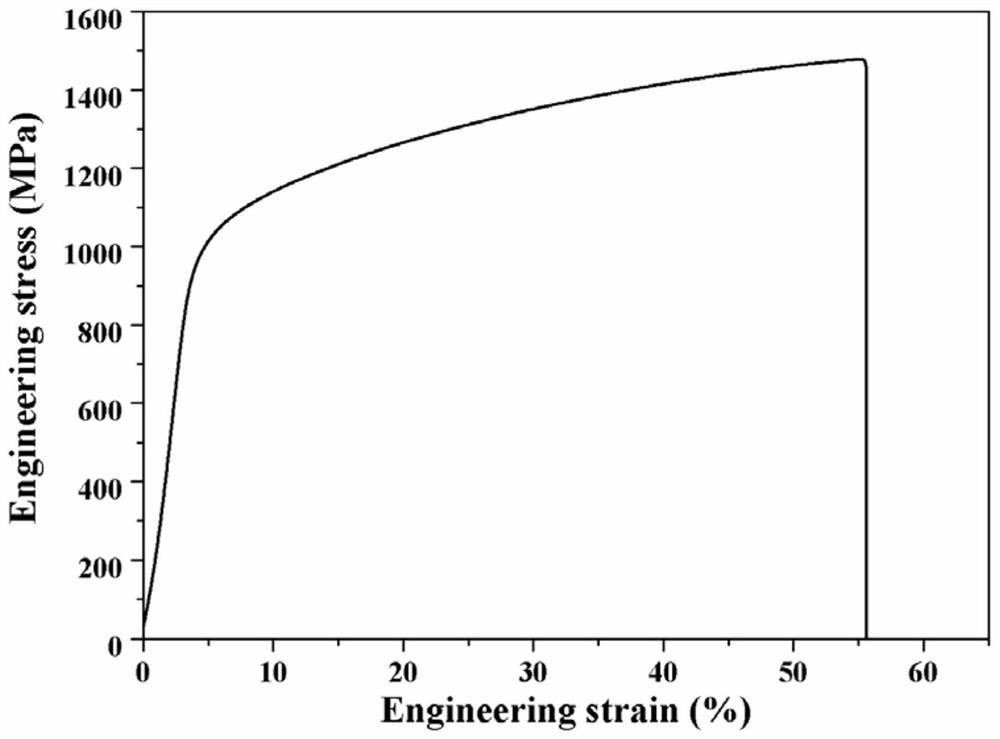

[0050] According to the nominal composition (Fe 40 mn 40 co 10 Cr 10 ) 99.3 C 0.6 Ti 1.5 The composition of the composition is batched, the total mass is about 200g, and it is smelted under the vacuum electric arc furnace for four times to obtain an as-cast alloy with a grain size of about 50μm; a single smelting of 200g ensures the uniformity and compactness of the composition and structure According to GB / T 13298-2015, GB / T 11352-2009 and GB / T 7233, samples were taken to test the uniformity and compactness. The results are: the chemical composition meets the design standards, and there is no shrinkage cavity.

[0051] The uniform and dense raw materials are tested, and the low-temperature tensile strength and plasticity of the as-cast alloy are tested. The tensile strength meets 500-2000MPa, the plasticity meets 10-100%, no subsequent treatment is required, the preparation is completed and can be used directly.

Embodiment 2

[0053] According to the nominal composition (Fe 40 mn 40 co 10 Cr 10 ) 99.2 C 0.6 Ti 1.7 The composition of the composition is batched, the total mass is about 200g, and it is smelted under the vacuum electric arc furnace for four times to obtain an as-cast alloy with a grain size of about 50μm; a single smelting of 200g ensures the uniformity and compactness of the composition and structure According to GB / T 13298-2015, GB / T 11352-2009 and GB / T 7233, samples were taken to test the uniformity and compactness. The results are: the chemical composition meets the design standards, and there is no shrinkage cavity.

[0054] The uniform and dense raw materials are tested, and the low-temperature tensile strength and plasticity of the as-cast alloy are tested. The tensile strength meets 500-2000MPa, the plasticity meets 10-100%, no subsequent treatment is required, the preparation is completed and can be used directly.

Embodiment 3

[0056] 1) According to the nominal composition (Fe 40 mn 40 co 10 Cr 10 ) 99.1 C 0.6 Ti 2 The composition of the composition is batched, the total mass is about 200g, and it is smelted under the vacuum electric arc furnace for four times to obtain an as-cast alloy with a grain size of about 50μm; a single smelting of 200g ensures the uniformity and compactness of the composition and structure According to GB / T 13298-2015, GB / T 11352-2009 and GB / T 7233, samples were taken to test the uniformity and compactness. The results are: the chemical composition meets the design standards, and there is no shrinkage cavity.

[0057] The uniform and dense raw materials are tested, and the low-temperature tensile strength and plasticity of the as-cast alloy are tested. The tensile strength meets 500-2000MPa, the plasticity meets 10-100%, no subsequent treatment is required, the preparation is completed and can be used directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com