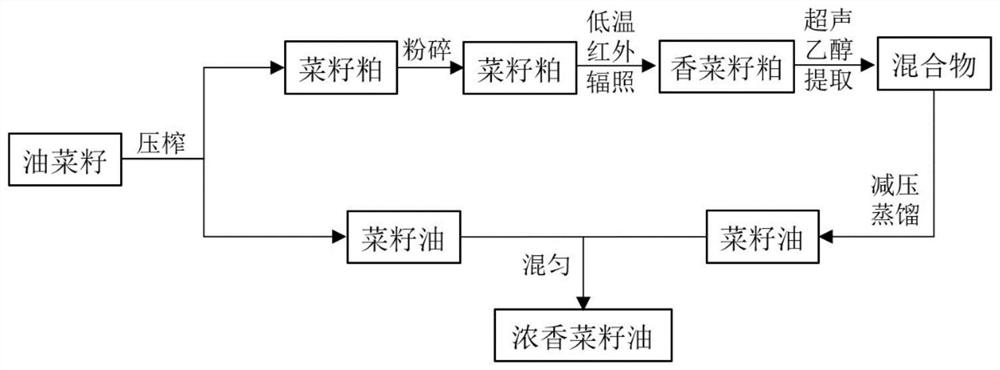

Method for preparing aromatic rapeseed oil by low-temperature infrared irradiation aroma-producing method

An infrared irradiation, rapeseed oil technology, applied in the production of fat, fat oil/fat production, fat oil/fat refining, etc., can solve problems such as unfavorable utilization of rapeseed meal, achieve high energy and penetration ability, phenolic content The effect of high and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Press 5kg of rapeseeds that have been screened and removed with a pressure of 30MPa and an oil outlet temperature of 30°C to obtain 1002.9g of virgin rapeseed oil. The obtained rapeseed meal is crushed and sprayed with 100g of distilled water. The lamp tube is 150mm, the power is 1kW, and it is irradiated at 120°C for 30 minutes; after the obtained rapeseed meal is cooled to room temperature, absolute ethanol is added according to the ratio of material to liquid for ultrasonic extraction. The ultrasonic power is 300W / kg, and the temperature is 40°C for 30 minutes; the filtered mixture was distilled and dried under reduced pressure to obtain 748.2 g of rapeseed oil, which was mixed with virgin rapeseed oil to obtain a total of 1751.1 g of rapeseed oil, with a total oil extraction rate of 35.02%.

[0031] Referring to the national standard, the acid value of the obtained rapeseed oil was measured to be 0.24mgKOH / g, the oxidation completion time of the rapeseed oil was 5.21...

Embodiment 2

[0034] Press 5kg of rapeseeds that have been screened and removed with a pressure of 30MPa and an oil outlet temperature of 30°C to obtain 1001.2g of virgin rapeseed oil. The obtained rapeseed meal is crushed and sprayed with 100g of distilled water. The lamp tube is 150mm, the power is 1kW, and it is irradiated at 130°C for 20min; after the obtained rapeseed meal is cooled to room temperature, absolute ethanol is added according to the material-to-liquid ratio of 1:1 for ultrasonic-assisted extraction. 40°C for 30 minutes; the filtered mixture was distilled and dried under reduced pressure to obtain 748.5 g of rapeseed oil, which was mixed with virgin rapeseed oil to obtain a total of 1749.7 g of rapeseed oil, with a total oil extraction rate of 34.99%.

[0035] Referring to the national standard, the acid value of the obtained rapeseed oil was measured to be 0.22mgKOH / g, the oxidation completion time of the rapeseed oil was 6.59h, and the tocopherol content in the oil was 746...

Embodiment 3

[0038] Press 5kg of rapeseed that has been screened and removed impurities, the pressure is 30MPa, the oil outlet temperature is 30°C, and 1007.5g of virgin rapeseed oil is obtained. The obtained rapeseed meal is crushed and sprayed with 100g of distilled water. The lamp tube is 150mm, the power is 1kW, and it is irradiated at 130°C for 30min; after the obtained rapeseed meal is cooled to room temperature, absolute ethanol is added according to the ratio of material to liquid at 1:1 for ultrasonic-assisted extraction. 40°C, the time is 30 minutes; the filtered mixed solution is distilled and dried under reduced pressure to obtain 752.9 g of rapeseed oil, which is mixed with virgin rapeseed oil to obtain rapeseed oil, and the total oil extraction rate is 35.21%.

[0039] Referring to the national standard, the acid value of the obtained rapeseed oil was measured to be 0.21mgKOH / g, the oxidation completion time of the rapeseed oil was 6.82h, and the tocopherol content in the oil wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com