Geopolymer composite material, concrete surface strain gauge using same and preparation method

A technology of concrete surface and composite material, which is applied in electric/magnetic solid deformation measurement, cement production, electromagnetic measurement device, etc., can solve the problems of easy failure, asynchronous concrete deformation, poor weather resistance of polymer materials, etc. The effect of avoiding errors and not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

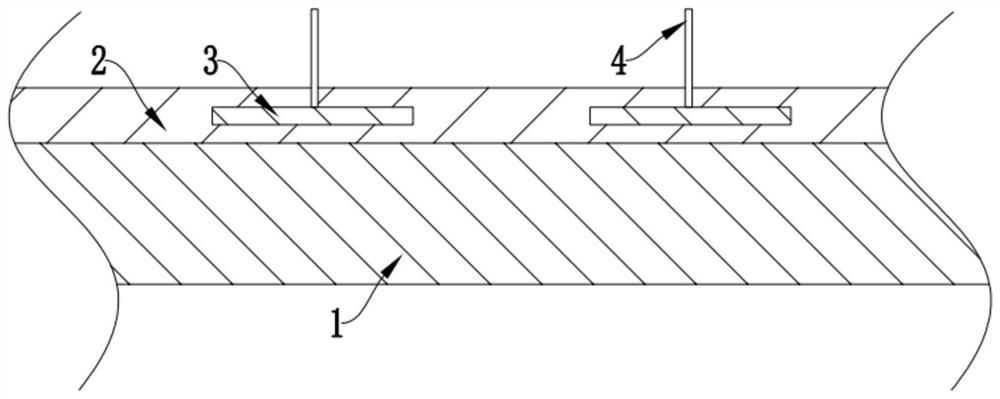

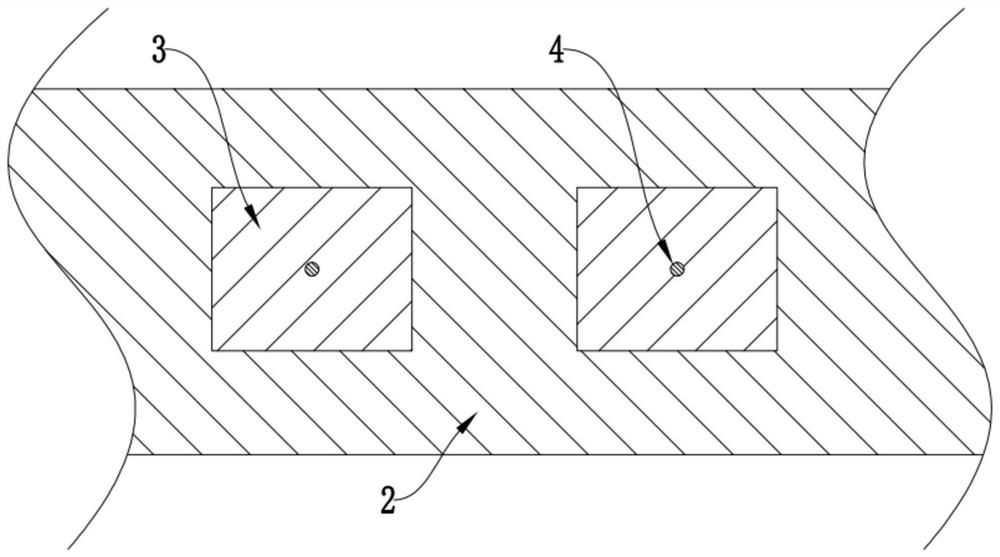

[0059] This technical solution further proposes a preparation method of a concrete surface strain gauge, which is used to prepare the above-mentioned concrete surface strain gauge, comprising the following steps:

[0060] (1) Mixing granulated blast furnace slag, fly ash and glass fiber according to the ratio to form powder;

[0061] (2) Stir the powder and the sodium base activator according to the proportioning ratio to form a composite material;

[0062] (3) The composite material is brushed on the surface of the concrete matrix 1 to be measured to form a base layer;

[0063] (4) placing the built-in electrode 3 connected with the external wire 4 on the surface of the base layer;

[0064] (5) The composite material is brushed on the surface of the base layer and the built-in electrode 3, and the concrete surface strain gauge is obtained after curing.

[0065] The technical scheme also proposes a preparation method of the concrete surface strain gauge, which has simple ste...

Embodiment 1

[0069] Embodiment 1-a kind of preparation method of concrete surface strain gauge

[0070] (1) 40 parts of S105 grade granulated blast furnace slag, 30 parts of first grade fly ash and 3 parts of glass fiber are mixed to form powder;

[0071] (2) 4 parts of powder and 2 parts of sodium silicate aqueous solution with a modulus of 3.3 and a concentration of 48% are stirred to form a composite material;

[0072] (3) The composite material is brushed on the surface of the concrete substrate to be measured to form a base layer;

[0073] (4) placing the built-in electrode connected with the external wire on the surface of the base layer;

[0074] (5) The composite material is brushed on the surface of the base layer and the built-in electrode, so that the built-in electrode is located inside the composite material, the external wire passes through the composite material and extends to the outside, and the concrete surface strain gauge is obtained after curing. Wherein, the cured c...

Embodiment 2

[0076] Embodiment 2-a kind of preparation method of concrete surface strain gauge

[0077] (1) 45 parts of S105 grade granulated blast furnace slag, 35 parts of first grade fly ash and 4 parts of glass fiber are mixed to form powder;

[0078] (2) 4 parts of powder and 3 parts of sodium silicate aqueous solution with a modulus of 3.4 and a concentration of 50% are stirred to form a composite material;

[0079] (3) The composite material is brushed on the surface of the concrete substrate to be measured to form a base layer;

[0080] (4) placing the built-in electrode connected with the external wire on the surface of the base layer;

[0081] (5) The composite material is brushed on the surface of the base layer and the built-in electrode, so that the built-in electrode is located inside the composite material, the external wire passes through the composite material and extends to the outside, and the concrete surface strain gauge is obtained after curing. Wherein, the cured c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com