Array carbon nanotube as well as preparation method and application thereof

A technology of carbon nanotubes and arrays, applied in the field of arrayed carbon nanotubes and its preparation, can solve the problems of uneven distribution of carbon nanotube diameters, poor quality of carbon nanotubes, loss of active sites, etc., and achieve good uniform diameter properties, inhibition of active component source agglomeration, and the effect of inhibiting deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

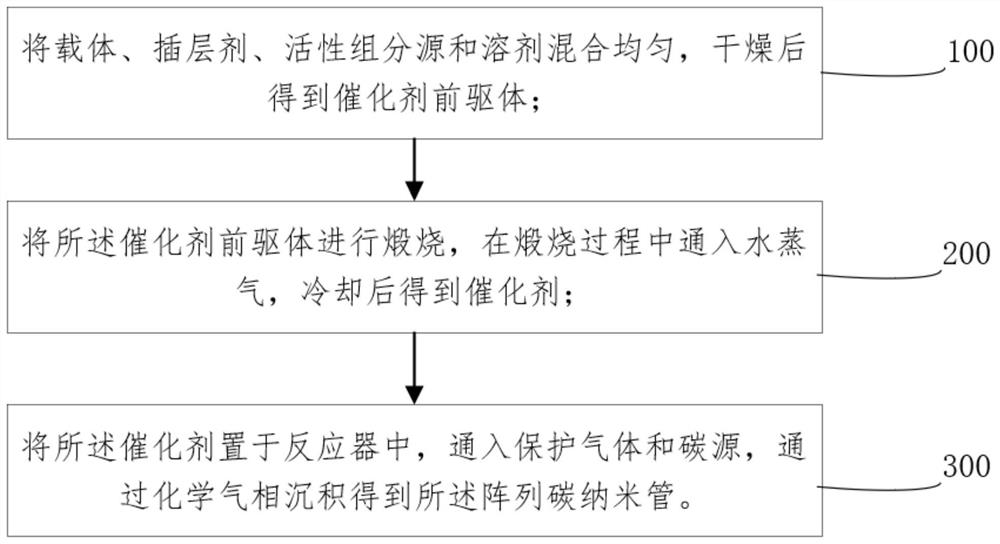

[0034] see figure 1 , which is a flowchart of a method for preparing arrayed carbon nanotubes provided in an embodiment of the present application, including:

[0035] Step 100: uniformly mixing the carrier, intercalation agent, active component source and solvent, and drying to obtain a catalyst precursor;

[0036] Step 200: calcining the catalyst precursor, injecting water vapor during the calcining process, and obtaining the catalyst after cooling;

[0037] Step 300: Put the catalyst in the reactor, pass through the protective gas and carbon source, and obtain the arrayed carbon nanotubes by chemical vapor deposition.

[0038] In the embodiment of the present application, in step 100, the carrier has a layered structure. In some embodiments of the present application, the carrier includes one or more of expanded graphite, mica stone, hydrotalcite (LDH), montmorillonite, kaolin and rectorite. The layered carrier has a large specific surface area and has a high loading cap...

Embodiment 1

[0060] A method for preparing an array of carbon nanotubes, comprising the steps of:

[0061] (1) Add 30g hydrotalcite to 150mL water, stir for 0.5h, then add 20g sodium dodecylbenzenesulfonate, stir at 25°C for 12h to form a uniform suspension; mix 48g cobalt nitrate hexahydrate and 8g nitric acid hexahydrate Lanthanum was added to the suspension, stirred and filtered to obtain a filter residue. Dry the filter residue at 100°C to obtain a catalyst precursor.

[0062] (2) The catalyst precursor was calcined in a muffle furnace at 550°C for 2h, preactivated by passing water vapor at 550°C for 30min, and cooled to room temperature to obtain the catalyst.

[0063] (3) Add 0.3 g of catalyst into the quartz boat, then move to the fixed-bed reactor, raise the temperature to 750 °C at 10 °C / min under the atmosphere of nitrogen protection gas, stop feeding nitrogen and switch to feeding ethylene. React at 750° C. for 30 minutes to obtain a crude carbon nanotube array.

[0064] (4) ...

Embodiment 2

[0068] A method for preparing an array of carbon nanotubes, comprising the steps of:

[0069] (1) In a mixed solution of 200mL water and ethanol (V 水 :V 乙醇 =1:1) by adding 30g of expanded graphite and 25g of cetyltrimethylammonium bromide, stirring at 40°C for 12h to form a uniform suspension; adding 50g of nickel nitrate and 6g of tungsten nitrate into the suspension, stirring and filtering to obtain filter residue. Dry the filter residue at 100°C to obtain a catalyst precursor.

[0070] (2) The catalyst precursor was calcined in a muffle furnace at 500°C for 3h, preactivated by passing water vapor at 500°C for 60min, and cooled to room temperature to obtain the catalyst.

[0071] (3) Add 0.5 g of catalyst into the quartz boat, then move to the fixed-bed reactor, raise the temperature to 650 °C at 15 °C / min under the atmosphere of nitrogen protection gas, stop feeding nitrogen and switch to feeding methane. React at 650° C. for 30 minutes to obtain a crude carbon nanotube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com