Aluminum-based gradient component multi-bypass premelting-TIG efficient forming device and method

A pre-melting and gradient technology, applied in the direction of improving energy efficiency, welding accessories, process efficiency, etc., can solve the problems of high time cost, low economic expectations, affecting the promotion and application of lightweight and high-performance functionally graded components, etc. The effect of low cost, cost reduction, and shortening of forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0028] The technical scheme that the present invention solves the problems of the technologies described above is:

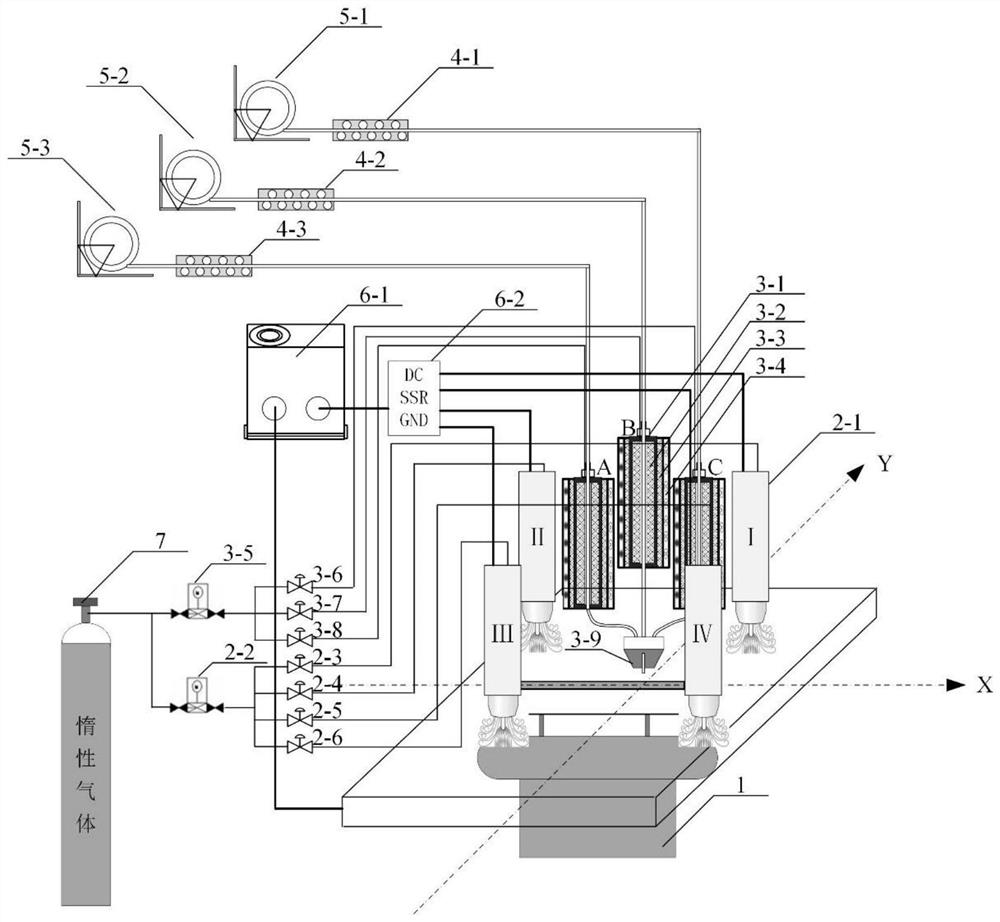

[0029] like figure 1 Shown:

[0030] The patent of the present invention discloses a metal material gradient structure multi-bypass premelting-TIG high-efficiency forming device, which includes at least three metal premelting units, namely, premelting unit A, premelting unit B and premelting unit C; and four TIG welding torch head, that is, No. Ⅰ TIG welding torch head, No. Ⅱ TIG welding torch head, No. Ⅲ TIG welding torch head and No. Ⅳ TIG welding torch head; also includes inert gas shielding gas device, stepping wire feeding unit, pulse argon arc welding machine.

[0031] Among them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com