Seed production and dust removal mechanical equipment with good dust removal effect

A technology for mechanical equipment and seeds, applied in the field of dust removal machinery and equipment for seed production, can solve problems such as choking and operator confusion, and achieve the effect of preventing choking and facilitating feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

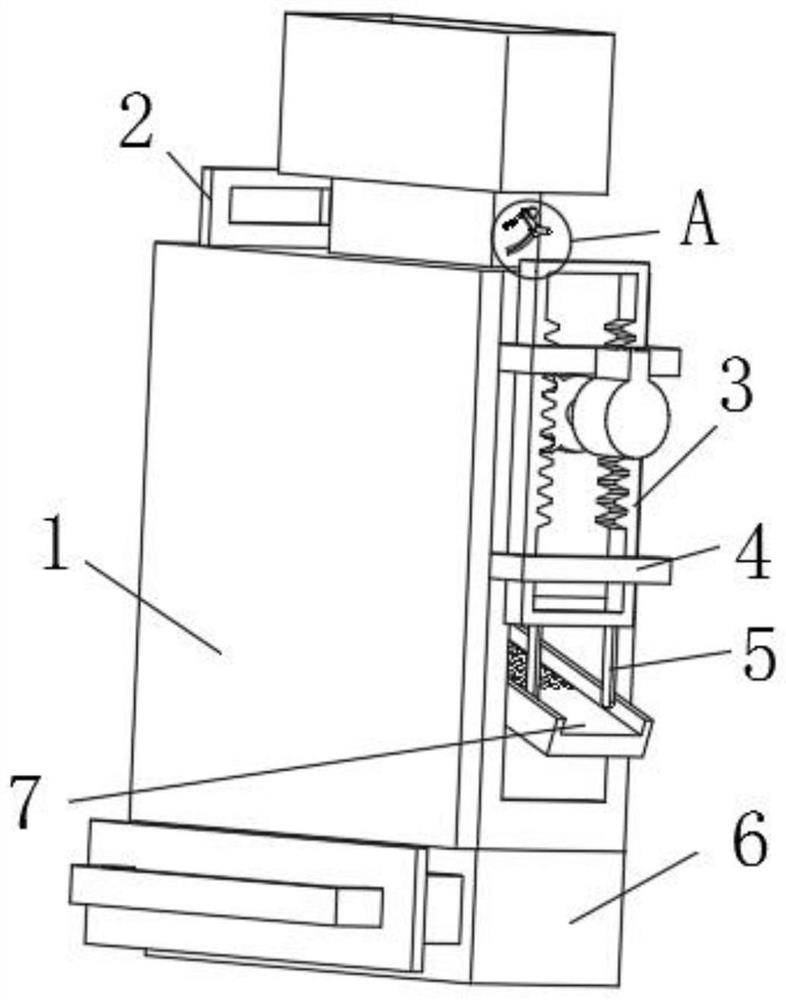

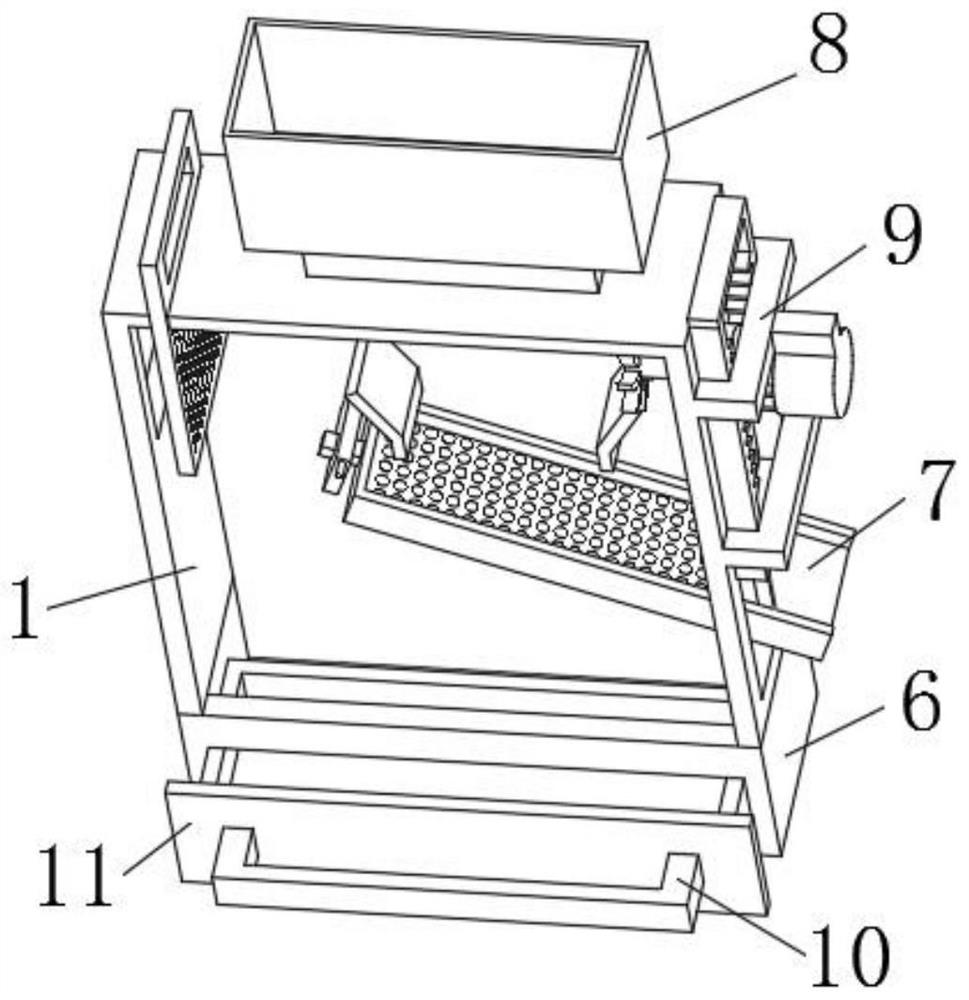

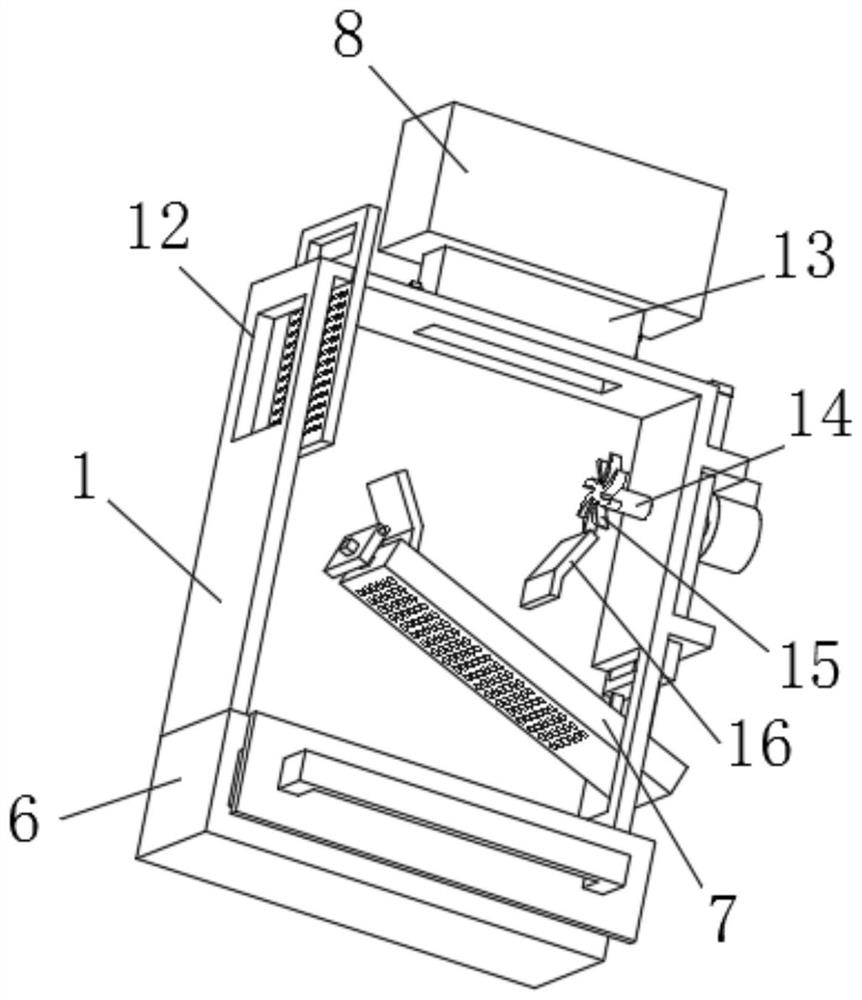

[0042] Example: Reference Figure 1-9 The shown dust removal mechanical equipment for seed production with good dust removal effect includes a dust removal box 1 on which a dust removal part, a screening part and a split feeding part are installed. Sliding slots, the top side of the dust removal box 1 is provided with sliding holes, the two sliding slots are connected with the sliding holes, and the same multi-layer adsorption filter screen 2 is slidably installed in the two sliding slots and the sliding holes, and the multi-layer adsorption filter screen 2 The bottom side of the multi-layer adsorption filter screen 2 includes two ordinary filter screen layers 26 and a dust adsorption filter screen layer 25, and the dust adsorption filter screen layer 25 is located in the middle of the two ordinary filter screen layers 26.

[0043] One side of the dust removal box 1 is fixedly installed with the first U-shaped pillar 4 and the second U-shaped pillar 9, and one side of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com