A collagen microfiber hemostatic material and its preparation method and use method

A technology of hemostatic material and collagen material, applied in application, pharmaceutical formulation, surgery and other directions, can solve the problems of non-dispersibility, large collagen fiber size, collagen material denaturation, etc., to maintain biological activity, fast hemostasis, and good hemostasis effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

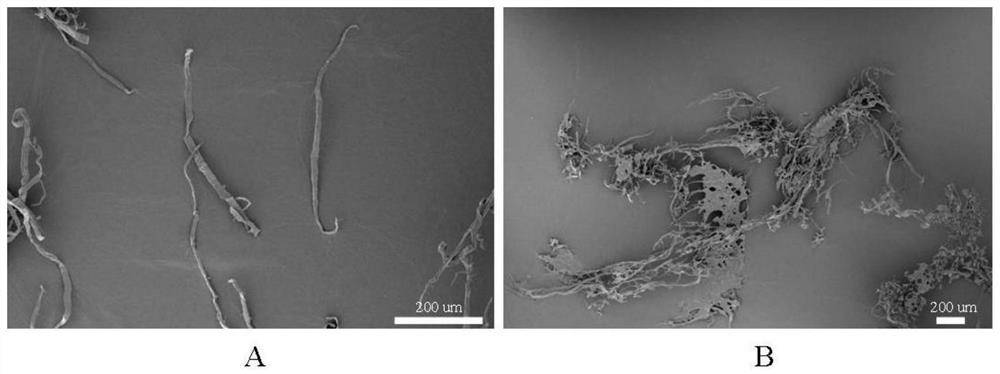

Image

Examples

Embodiment 1

[0035] A preparation method of collagen microfiber hemostatic material, wherein, the following steps are included in sequence:

[0036] (1) High-speed shearing of the cross-linked 5g collagen sheet on a high-speed pulverizer, wherein the rotating speed of the high-speed pulverizer is 30000r / min, and the pulverization time is 30s;

[0037] (2) uniformly dispersing the collagen microfiber raw material in step (1) in 500 g of deionized water to prepare a collagen microfiber suspension;

[0038] (3) filtering the collagen microfiber suspension in step (2) through a 30-150 mesh screen, screening to obtain a collagen microfiber raw material with a length of 100-500um, and dispersing in water to prepare a collagen microfiber suspension;

[0039] (4) adding 50 mg of fibrinogen and 2 mg of calcium chloride to the collagen microfibril suspension in step (3);

[0040] (5) adding 5 mg glutaraldehyde and 10 mg NHS ester to the collagen microfibril suspension in step (4), and the reaction ...

Embodiment 2

[0045] A preparation method of collagen microfiber hemostatic material, wherein, the following steps are included in sequence:

[0046] (1) High-speed shearing of 10g collagen film on a high-speed pulverizer, wherein the rotating speed of the high-speed pulverizer is 20000r / min, and the pulverization time is 20s;

[0047] (2) uniformly dispersing the collagen microfiber raw material in step (1) in 100,000 g of deionized water to prepare a collagen microfiber suspension;

[0048] (3) filtering the collagen microfiber suspension in step (2) through a 16-40 mesh screen, screening to obtain a collagen microfiber raw material with a length of 400-1000um, and dispersing in water to prepare a collagen microfiber suspension;

[0049] (4) adding 0.5 mg prothrombin and 0.01 mg platelet cofactor I to the collagen microfibril suspension in step (3);

[0050] (5) adding 2g ethylene oxide and 1g proanthocyanidin in step (4) collagen microfiber suspension, the reaction time is 60min;

[00...

Embodiment 3

[0055] A preparation method of collagen microfiber hemostatic material, wherein, the following steps are included in sequence:

[0056] (1) High-speed shearing of 2g collagen sponge on a high-speed pulverizer, wherein the rotating speed of the high-speed pulverizer is 60000r / min, and the pulverization time is 10s;

[0057] (2) uniformly dispersing the collagen microfiber raw material in step (1) in 500 g of deionized water to prepare a collagen microfiber suspension;

[0058] (3) filtering the collagen microfiber suspension in step (2) through a 80-1000 mesh screen, screening to obtain a collagen microfiber raw material with a length of 10-200um, and dispersing it in water to prepare a collagen microfiber suspension;

[0059] (4) adding 1 mg of prothrombinase to the collagen microfibril suspension in step (3);

[0060] (5) adding 0.02g carbodiimide and 5g genipin in step (4) collagen microfiber suspension, the reaction time is 120min;

[0061] (6) the collagen microfibril su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com