Preparation method of Ti-Mn porous anode material for electrolysis of manganese dioxide

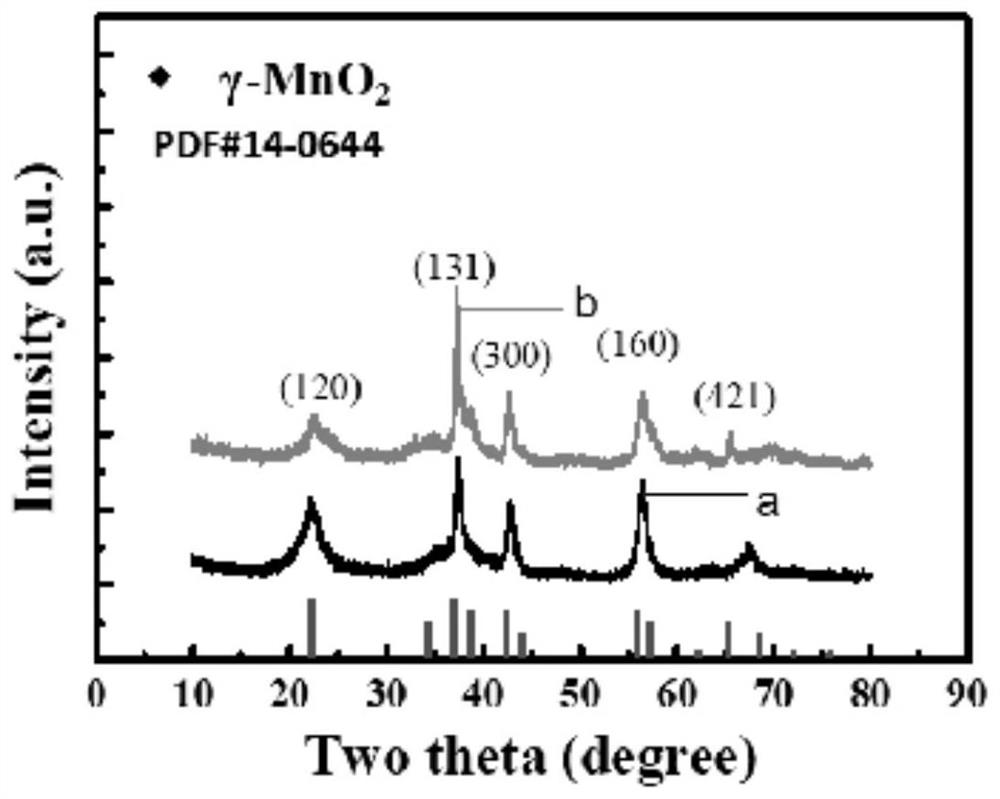

A technology of electrolytic manganese dioxide and porous anode, which is applied in electrode coatings, electrodes, electrolytic components, etc., can solve the problem that the mechanical properties of manganese permeated titanium plates are greatly affected, the preparation cost of manganese permeated titanium plate anodes is high, and the composition of Ti-Mn is inconsistent. stability and other issues, to achieve good anti-passivation ability, good anode electrocatalytic activity, and rich pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

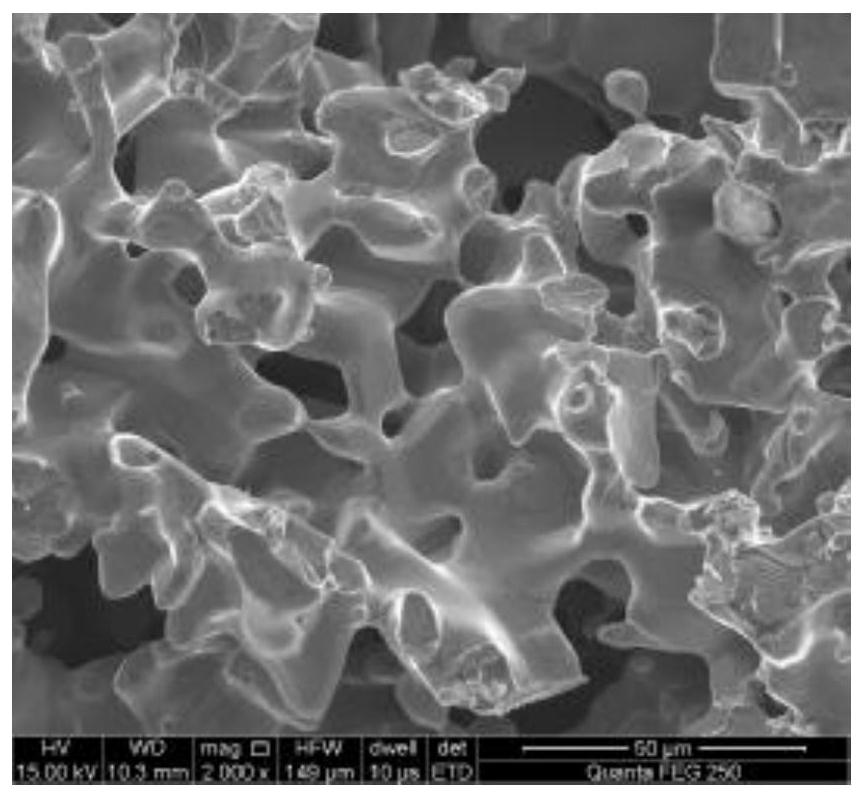

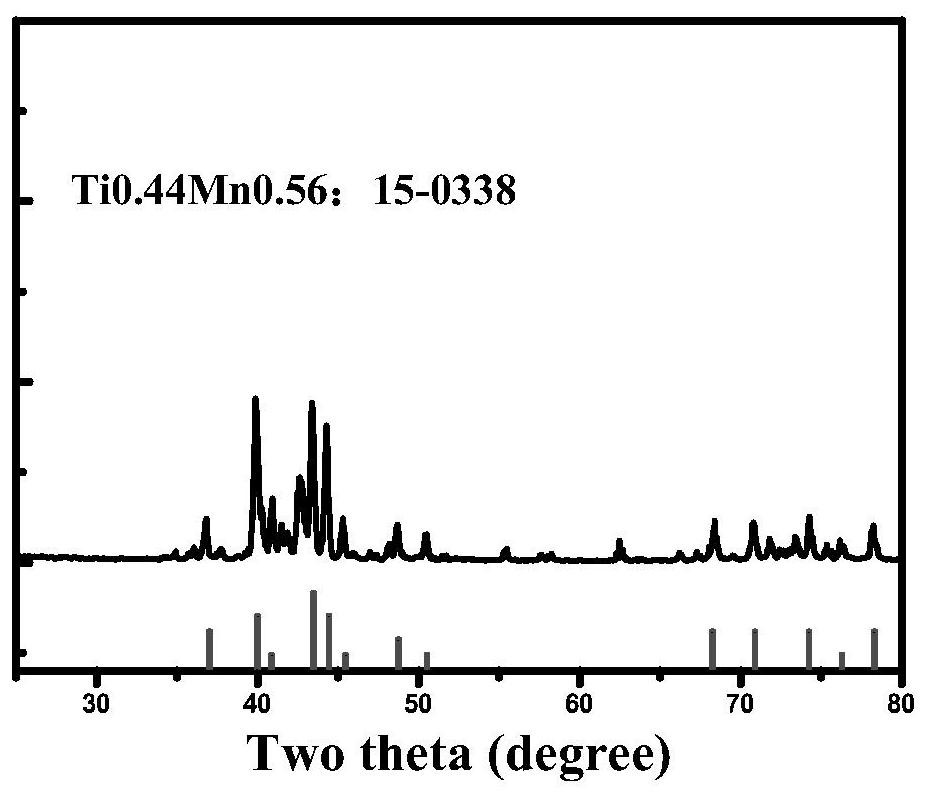

[0025] Example 1: 100g Ti powder (-400 mesh, purity>99.8 wt.%) and 130g electrolytic Mn powder (-400 mesh, purity>99.8 wt.%) were mixed for 24 hours under nitrogen protection, and 8.0g glycerin was taken Mix with 80mL ethanol, then fully mix Ti / Mn mixed powder with glycerin / ethanol mixed solution to granulate; take the granulated Ti / Mn mixed powder and press to form, the pressure is 120 MPa, and the preform thickness is 4.2mm. Place the preform in a vacuum sintering furnace, raise the temperature to 350°C at a rate of 3°C / min, and then hold it for 3 hours, then raise the temperature to 500°C at a rate of 3°C / min and hold it for 2 hours to ensure the stable decomposition of the polymer binder; Subsequently, the temperature was raised to 1100 °C at a rate of 2 °C / min for 3.5 hours, and the cooling period was set at 1000 °C for 3 hours to obtain a Ti-Mn metal porous anode material. The average pore diameter is 22.5μm, the open porosity is 41.0%, and the bending strength is 48MPa....

Embodiment 2

[0027] Example 2: 100g Ti powder (-400 mesh, purity>99.8 wt.%) and 130g electrolytic Mn powder (-400 mesh, purity>99.8 wt.%) were mixed for 24 hours under nitrogen protection, and 8.0g glycerin was taken Mix with 80mL of ethanol, then fully mix the Ti / Mn mixed powder with glycerin / ethanol mixed solution to granulate; take the granulated Ti / Mn mixed powder and press to form, the pressure is 150 MPa, and the thickness of the preform is 3.9mm. Place the preform in a vacuum sintering furnace, raise the temperature to 350°C at a rate of 3°C / min, and then hold it for 4 hours, then raise the temperature to 500°C at a rate of 3°C / min and hold it for 3 hours to ensure the stable decomposition of the polymer binder; Subsequently, the temperature was raised to 1100 °C at a rate of 2 °C / min for 3.5 hours, and the cooling period was set at 1000 °C for 3 hours to obtain a Ti-Mn metal porous anode material. The average pore diameter is 18.7μm, the open porosity is 39.8%, and the bending stre...

Embodiment 3

[0028]Example 3: 100g Ti powder (-400 mesh, purity>99.8 wt.%) and 130g electrolytic Mn powder (-400 mesh, purity>99.8 wt.%) were mixed for 24 hours under nitrogen protection, and 8.0g glycerin was taken Mix with 80mL ethanol, then fully mix the Ti / Mn mixed powder and glycerin / ethanol mixed solution to granulate; take the granulated Ti / Mn mixed powder and press to form, the pressure is 200 MPa, and the thickness of the preform is 3.5mm. Place the preform in a vacuum sintering furnace, raise the temperature to 350°C at a rate of 3°C / min, and then hold it for 4.5 hours, then raise the temperature to 500°C at a rate of 3°C / min and hold it for 3.5 hours to ensure the stable decomposition of the polymer binder; Subsequently, the temperature was raised to 1100 °C at a rate of 2 °C / min for 3.5 hours, and the cooling period was set at 1000 °C for 3 hours to obtain a Ti-Mn metal porous anode material. The average pore diameter is 15.5μm, the open porosity is 37.0%, and the bending stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com