Laser spot shaping device and method for preparing single cladding layer

A technology of laser spot and shaping device, which is applied in optics, coatings, optical components, etc., can solve the problems of uneven heating of circular Gaussian spot, low thickness of single-layer cladding layer, and high lap rate, so as to improve cladding. Efficiency, widening lateral coverage, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

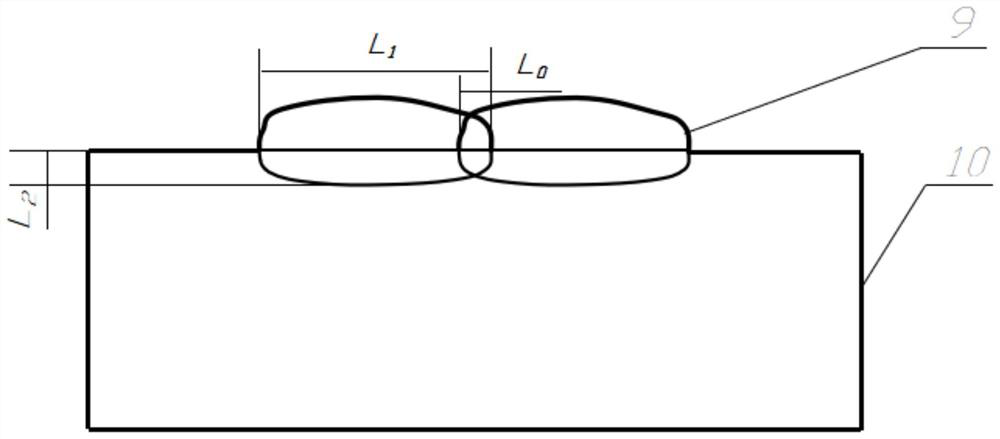

[0054]Step S1: The 9Cr2MO base 10 having a size of 100 mm × 100 mm × 20 mm is prepared, and the surface of the substrate 10 is prepared, and the surface stain and the oxide pretreatment are removed;

[0055]Step S2: Place the substrate 10 in a thermostat of 350 ° C for 0.5 h, preheating;

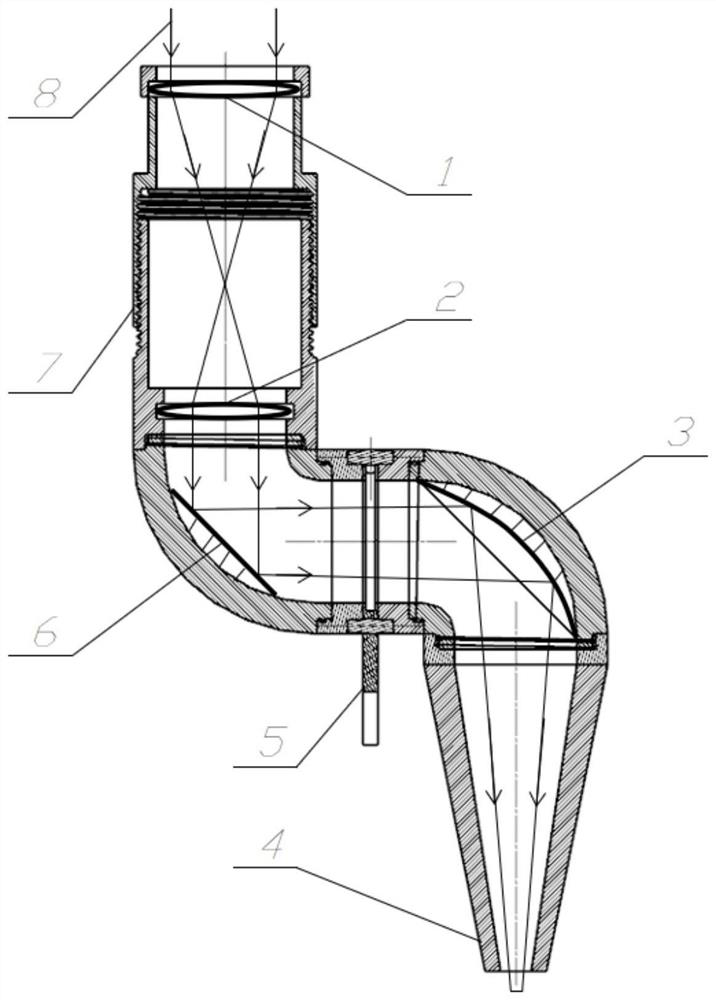

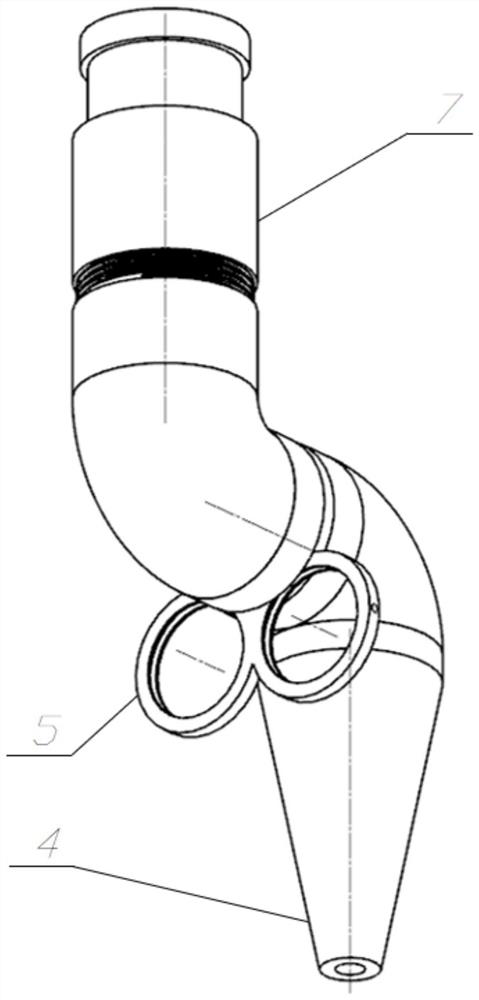

[0056]Step S3: Set the laser welding process parameter: the laser output power is 4000W, the scanning speed is 300mm / min, the amount of powder is 15 g / min, the extraction is 68mm, the argon gas flow is 20L / min, the road is lapsed The rate is 10%, and the laser beam is bleed, and the laser beam is generated, and a flat rectangular spot of 3 mm × 1 mm is formed.

[0057]Step S4: 5% of the WC ceramic particle reinforcement phase was added to the Fe based alloy powder having a powder particle size of 50 μm, and the molten coating was carried out by a single layer of a single layer, the synchronous powder feed mode, so that the alloy powder was reacted with the substrate 10, resulting in a sample ;

[0058]S...

Embodiment 2

[0062]Step S1: The 9Cr2MO base 10 having a size of 100 mm × 100 mm × 20 mm is prepared, and the surface of the substrate 10 is prepared, and the surface stain and the oxide pretreatment are removed;

[0063]Step S2: Place the substrate 10 in a thermostat of 350 ° C for 0.5 h, preheating;

[0064]Step S3: Set the laser welding process parameter: the laser output power is 4000W, the scanning speed is 300mm / min, the amount of powder is 15 g / min, the extraction is 68mm, the argon gas flow is 20L / min, the road is lapsed The rate is 20%, and the laser beam is generated by the laser photometric shaping device, and a flat top square spot of 2 mm × 2 mm is formed;

[0065]Step S4: Add 10% WC ceramic particle reinforcement phase to the FE-based alloy powder having a powder particle size of 70 μm, and is subjected to a single layer, a synchronous powder feed mode, so that the alloy powder is reacted with the substrate 10 to obtain a sample. ;

[0066]Step S5: In order to further improve the surface ...

Embodiment 3

[0070]Step S1: The 9Cr2MO base 10 having a size of 100 mm × 100 mm × 20 mm is prepared, and the surface of the substrate 10 is prepared, and the surface stain and the oxide pretreatment are removed;

[0071]Step S2: Place the substrate 10 in a thermostat of 350 ° C for 0.5 h, preheating;

[0072]Step S3: Set the laser welding process parameter: the laser output power is 4000W, the scanning speed is 300mm / min, the amount of powder is 15 g / min, the extraction is 68mm, the argon gas flow is 20L / min, the road is lapsed The rate is 50%, and the laser beam is generated by the above laser photometric shaping device, and the flat-top circular spot of R = 1 mm is formed.

[0073]Step S4: Add 15% WC ceramic particle reinforcement phase in a Fe base alloy powder having a powder particle size of 90 μm, and is subjected to a single layer, a synchronous feed powder, so that the alloy powder is reacted with the substrate 10 to obtain a sample. ;

[0074]Step S5: In order to further improve the surface l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com