Vanadium extraction converter and top-bottom combined blowing method

A technology for converters and top-blown oxygen lances, applied in the manufacture of converters, etc., can solve problems such as inability to achieve large flow bottom blowing, shortened life, easy to corrode, etc., to avoid serious reduction in life, reduce corrosion, fully uniform and rapid stirring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The invention relates to a vanadium extraction converter and a top-bottom compound blowing method.

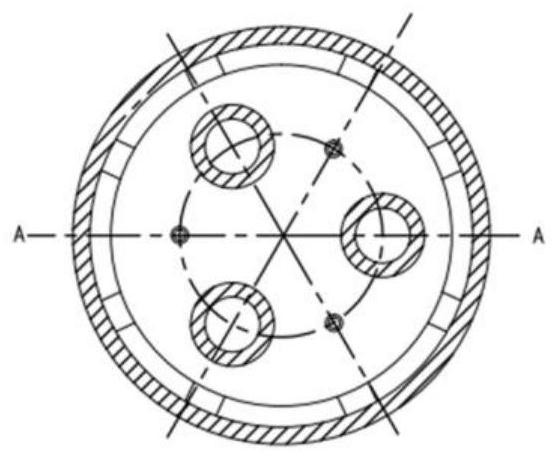

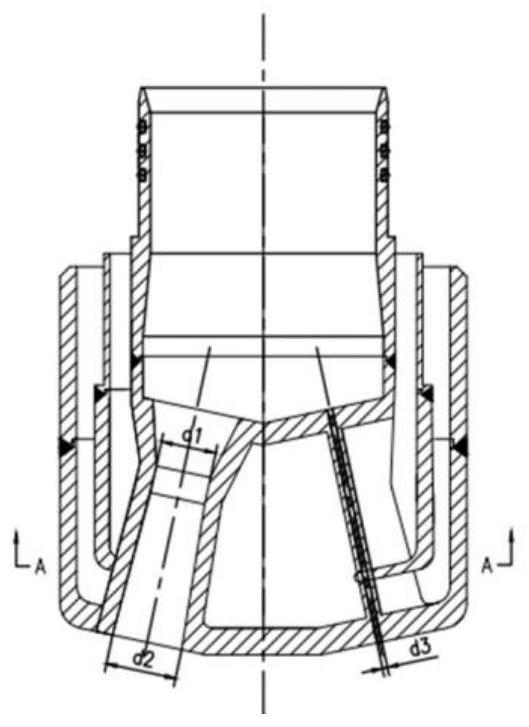

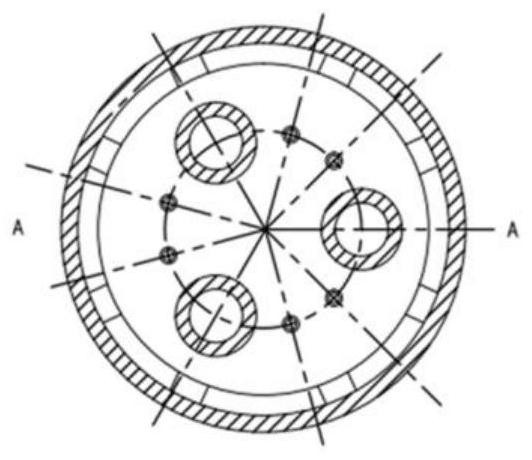

[0075] The bottom blowing element consists of three layers of coaxial sleeves, the inner pipe is fed with nitrogen, the methane gas is passed between the inner wall of the middle pipe and the outer wall of the inner pipe, and the nitrogen gas is passed between the inner wall of the outer pipe and the outer wall of the middle pipe. The difference between the inner diameter of the outer tube and the outer diameter of the middle tube ΔD 1 =4mm, the difference between the inner diameter of the middle tube and the outer diameter of the inner tube ΔD 2 = 4mm, the inner diameter of the inner tube ΔD 3 = 6mm. Outer tube diameter D1 = 26mm, wall thickness 2mm; middle tube outer diameter D2 = 18mm, wall thickness 2mm; inner tube outer diameter D3 = 10mm, wall thickness 2mm. The corresponding bottom blowing flow rate is: outer tube 8Nm 3 / h·t, middle tube 0.8Nm 3 / h·t, inner t...

Embodiment 2

[0083] The invention relates to a vanadium extraction converter and a top-bottom compound blowing method.

[0084] The bottom blowing element consists of three layers of coaxial sleeves, the inner pipe is fed with nitrogen, the methane gas is passed between the inner wall of the middle pipe and the outer wall of the inner pipe, and the nitrogen gas is passed between the inner wall of the outer pipe and the outer wall of the middle pipe. Nitrogen gas is passed between the inner wall of the outer tube and the outer wall of the middle tube. The difference between the inner diameter of the outer tube and the outer diameter of the middle tube ΔD 1 =5mm, the difference between the inner diameter of the middle tube and the outer diameter of the inner tube ΔD 2 = 3mm, the inner diameter of the inner tube ΔD 3 = 4 mm. Outer tube diameter D1 = 24mm, wall thickness 2mm; middle tube outer diameter D2 = 15mm, wall thickness 2mm; inner tube outer diameter D3 = 8mm, wall thickness 2mm. T...

Embodiment 3

[0092] The invention relates to a vanadium extraction converter and a top-bottom compound blowing method.

[0093] The bottom blowing element consists of three layers of coaxial sleeves, the inner pipe is fed with nitrogen, the methane gas is passed between the inner wall of the middle pipe and the outer wall of the inner pipe, and the nitrogen gas is passed between the inner wall of the outer pipe and the outer wall of the middle pipe. Nitrogen gas is passed between the inner wall of the outer tube and the outer wall of the middle tube. The difference between the inner diameter of the outer tube and the outer diameter of the middle tube ΔD 1 =6mm, the difference between the inner diameter of the middle tube and the outer diameter of the inner tube ΔD 2 =6mm, the inner diameter of the inner tube ΔD 3 = 4 mm. Outer tube diameter D1 = 28mm, wall thickness 2mm; middle tube outer diameter D2 = 18mm, wall thickness 2mm; inner tube outer diameter D3 = 8mm, wall thickness 2mm. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com