Production strain for producing lactic acid monomer by using sucrose as raw material and obtaining method thereof

A technology for the production of bacterial strains and lactic acid monomers, applied in the fields of fermentation engineering and genetic engineering, can solve problems such as the inability to efficiently utilize sucrose, achieve the effects of improving economic benefits and industrial structure, optimizing production technology, and expanding raw material supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Free secreted expression of sucrase

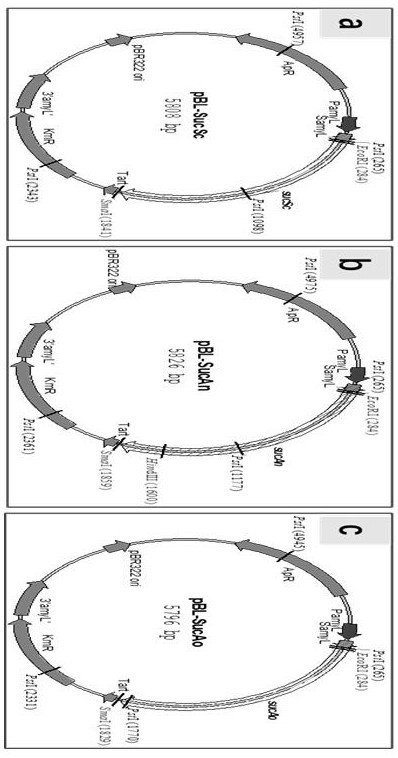

[0053] Codon optimization and chemical synthesis were carried out on the sucrase coding genes derived from Saccharomyces cerevisiae, Aspergillus niger and Aspergillus oryzae (respectively shown in SEQ ID NO.1, 3, 5), and the synthetic gene sequences were amplified by PCR (primers See Table 1), PCR amplification products were used Eco After digestion with RI, clone into pBL-WZX to obtain the recombinant expression plasmid pBL-SucSc (attached figure 1 a), pBL-SucAn (attached figure 1 b) and pBL-SucAo (attached figure 1 c).

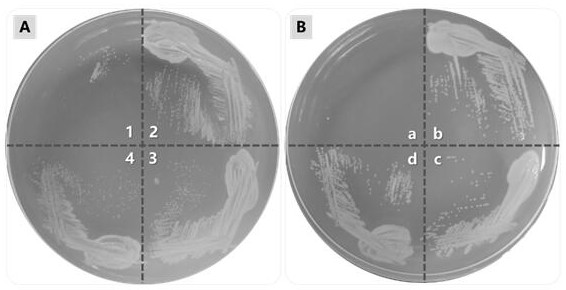

[0054] The expression plasmids pBL-SucSc, pBL-SucAn and pBL-SucAo were respectively transformed into the lactic acid monomer production strain CGMCC 11059 to obtain the corresponding recombinant bacteria SEC168D, SEC168D1 and SEC168D2; transformed into the lactic acid monomer production strain CGMCC 11060 to obtain the corresponding The recombinant strains SEC168L, SEC168L1 and SEC168L2.

[0055...

Embodiment 2

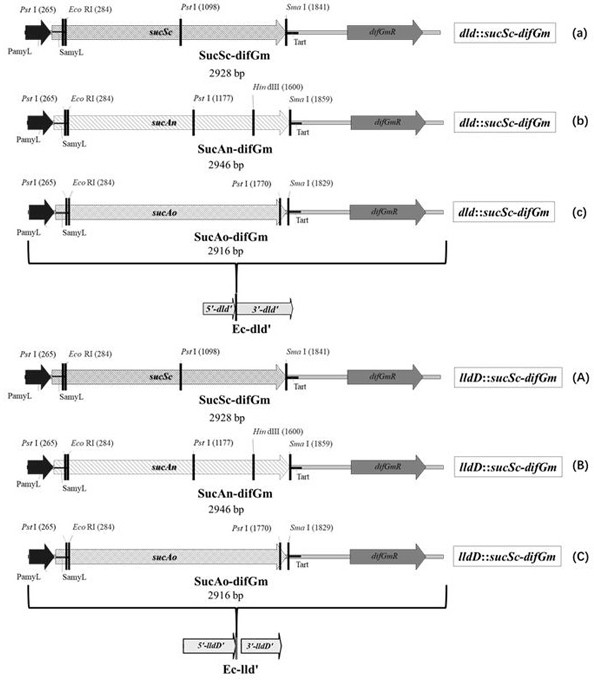

[0060] Example 2 Integrate, secrete and express sucrase

[0061] Use primers Pec1 and Pec2 (Table 1) to amplify the recombinant secreted and expressed invertase constructed in Example 1, respectively. sucSc , sucAn and sucAo Expression cassette, including promoter, signal peptide sequence, sucrase coding gene and terminator sequence.

[0062] Using Escherichia coli chromosomal DNA as a template, primers P7 and P8 (Table 1) were used to amplify about 0.9 kb dld gene fragment, with Eco Removal of RV dld The about 0.4 kb fragment in the middle of the gene will be derived from the pSK-difGm dif Gm cloned into it, obtained with dld recombined fragments of homology arms dld :: dif Gm; the sucrase obtained above sucSc , sucAn and sucAo expression cassette insertion dif outside of Gm Stu I site, to obtain the site-directed integration expression cassette expressing sucrase dld :: sucSc- difGm (attached image 3 a), dld :: sucSc-difGm (attached ...

Embodiment 3

[0067] Example 3 Production of Lactic Acid Monomers from Sucrose by Recombinant Bacteria under Feeding Process

[0068] Inoculate the seed solution (secondary seed solution) of lactic acid producing strains into 150 mL of M9 liquid medium supplemented with 0.5 wt.% sucrose, and culture it on a shaker at 37°C and 200 r / min for 10 h, then take the culture solution According to the initial OD value of 0.3, the inoculum was inoculated in the M9 liquid medium with a sucrose concentration of 30 g / L. After inoculation, the initial volume of the 50 L fermenter was 25 L, the temperature was controlled at 37 ° C, the ventilation rate was 1.5 vvm, and the stirring The rotation speed was 1000 r / min, and the pH was maintained at 6.5 with ammonia water; when the cell concentration reached OD600 of 30, the ventilation was turned off, the stirring speed was 200 r / min, and the fermentation temperature was controlled at 40°C. The total amount of sucrose added is about 240 g / L) added to the ferm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com