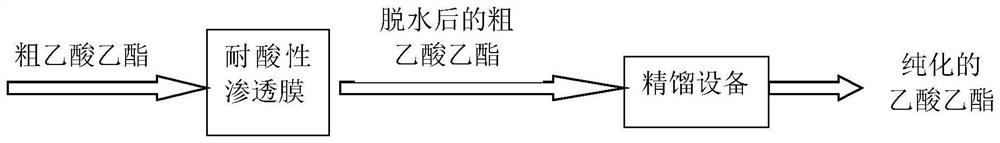

Method for purifying ethyl acetate

A technology of ethyl acetate and crude ethyl acetate, which is applied in the field of ethyl acetate, can solve the problems of non-recyclable, high energy consumption, and complicated operation, so as to reduce purification energy consumption, low energy consumption, and reduce purification cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The crude ethyl acetate is composed of ethyl acetate, water, and ethanol solvent. According to mass percentage, ethyl acetate accounts for 94wt%, water accounts for 3.5wt%, and ethanol accounts for 2.5wt%.

[0045] The acid-resistant permeable membrane is a silica membrane.

[0046] 100kg of crude ethyl acetate was separated and dehydrated through an acid-resistant permeable membrane at a flow rate of 5kg / h. After dehydration, the water content on the crude ethyl acetate side was 0.5wt%, and the water content on the permeate side of the membrane was 99.4wt%. Then, ethanol was removed from the dehydrated crude ethyl acetate through rectification, the temperature at the top of the rectification column was 76.8°C, and purified ethyl acetate was obtained from the bottom of the column according to the reflux ratio of 20:1.

[0047] In this example, the yield of ethyl acetate was 86.5%, and the purity was 99.93%.

Embodiment 2

[0049] Crude ethyl acetate is composed of ethyl acetate, water, ethanol, and toluene solvent. According to mass percentage, ethyl acetate accounts for 94wt%, water accounts for 3.5wt%, ethanol accounts for 2wt%, and toluene accounts for 0.5wt%.

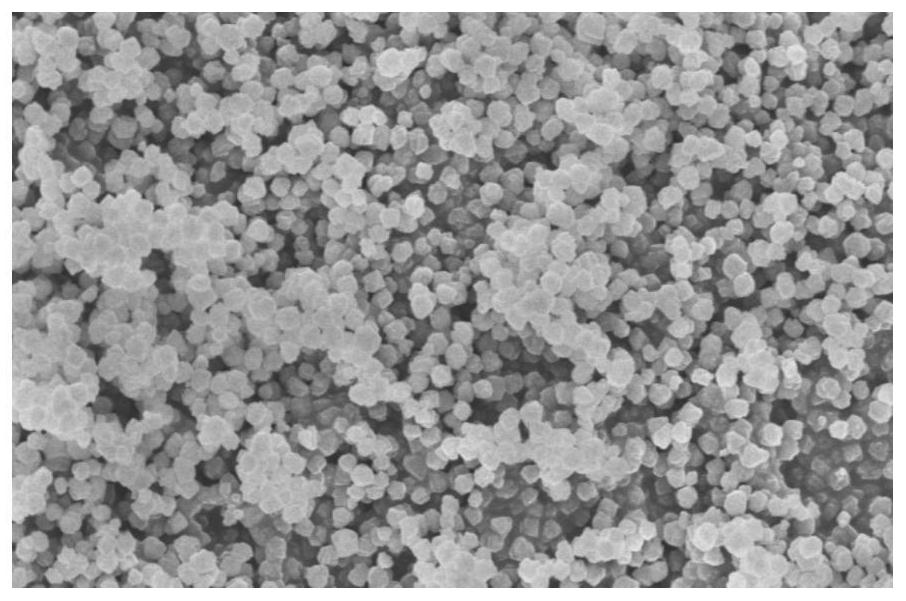

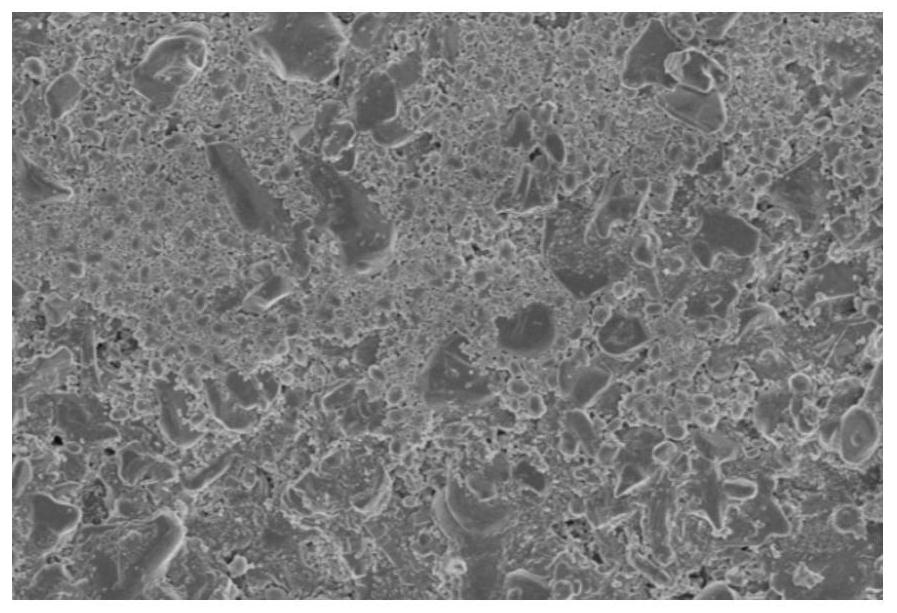

[0050] The acid-resistant permeable membrane is T / NaY zeolite molecular sieve composite membrane. Porous α-Al 2 o 3 A hollow ceramic fiber tube is used as a support carrier, with a diameter of 12 mm and an average pore diameter of 2 μm. The T / NaY zeolite molecular sieve composite membrane is prepared on the porous carrier.

[0051] The preparation method mainly includes two parts: firstly, a continuous NaY zeolite molecular sieve coating is prepared on a porous carrier to obtain a NaY zeolite molecular sieve coating modified carrier; then a T-type zeolite is prepared on the NaY zeolite molecular sieve coating modified carrier by a hydrothermal method. Molecular sieve membrane. Specifically include the following steps:

[0052] (1...

Embodiment 3

[0072] The crude ethyl acetate is composed of ethyl acetate, water, and ethanol solvent. According to mass percentage, ethyl acetate accounts for 94.5wt%, water accounts for 3.5wt%, and ethanol accounts for 2wt%.

[0073] The acid-resistant permeable membrane is a silicone membrane.

[0074] 100kg of crude ethyl acetate was separated and dehydrated through an acid-resistant permeable membrane at a flow rate of 160kg / h. After dehydration, the water content on the crude ethyl acetate side was 0.6wt%, and the water content on the permeate side of the membrane was 99.3wt%. Then, the dehydrated crude ethyl acetate was removed by rectification to remove ethanol. The temperature at the top of the rectification tower was 76.8°C, and purified ethyl acetate was obtained from the bottom of the tower according to the reflux ratio of 20:1.

[0075] In this example, the yield of ethyl acetate was 85.3%, and the purity was 99.99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com