Preparation method of nitrogen and phosphorus doped porous carbon for oxygen reduction electrocatalysis in wide pH range

An electrocatalysis and phosphorus doping technology, which is applied in the preparation/purification of carbon, circuits, electrical components, etc., can solve the problems of insufficient research on oxygen reduction electrocatalysts in fuel cells, and achieve a simple and feasible preparation process and good flake morphology. Beneficial and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

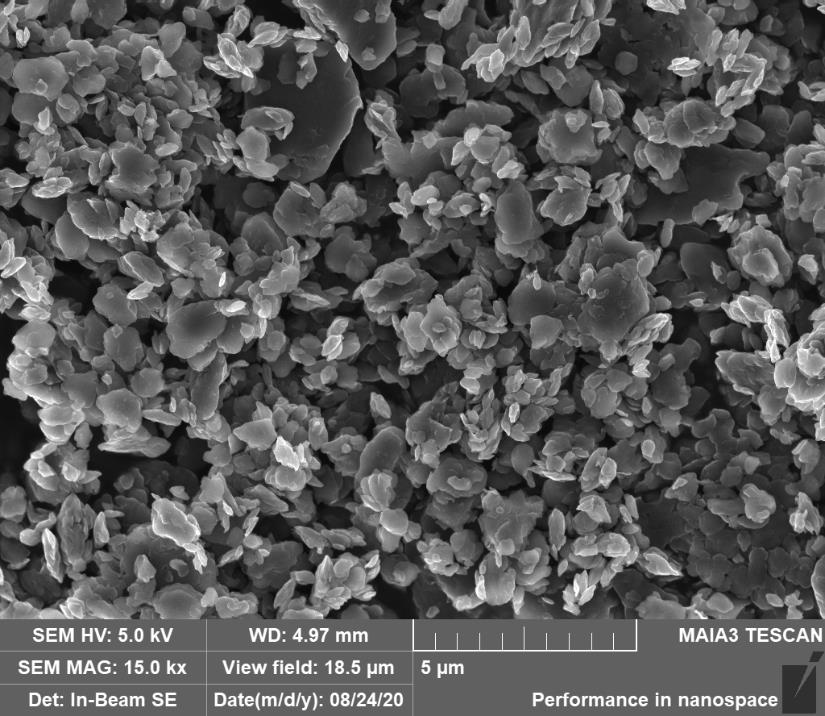

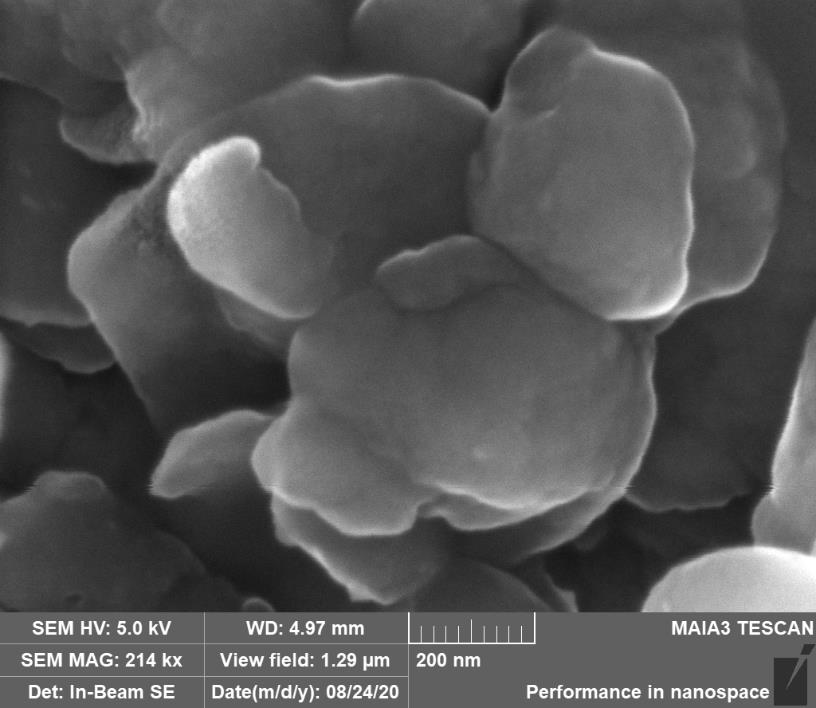

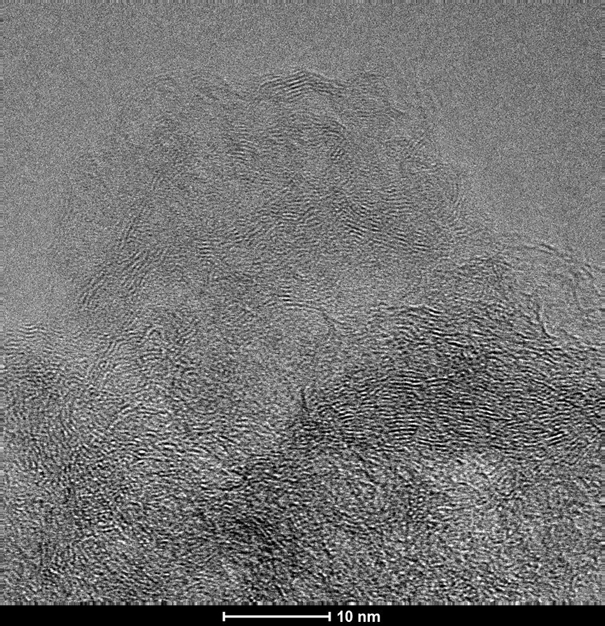

[0059] Weigh the pretreated coal and phosphoric acid according to the mass ratio of 1:4, add water to dilute and ultrasonically mix, the specific ultrasonic parameters are 25 Hz (5 min), 33 Hz (10 min), 40 Hz (5 min), 59 Hz (10 min), the total time is 0.5h, and then dried and transferred to a tube furnace, under a nitrogen atmosphere at 3 ℃ min –1 The heating rate was carbonized at 900 °C for 1 h, and after the carbonization was completed, it was taken out, pickled, filtered, washed with water, and dried to obtain phosphorus-doped carbon P 4 C-900: Weigh phosphorus-doped carbon, melamine and potassium hydroxide according to the mass ratio of 1:4:2, grind and mix them, transfer them to a tube furnace, and heat them at 3 °C min under a nitrogen atmosphere. –1 The heating rate was carbonized at 900 ℃ for 2 h to obtain the secondary carbonized product; the secondary carbonized product was mixed with 1mol L –1 Pickle with dilute hydrochloric acid solution for 1-3 h, filter, wash w...

Embodiment 2

[0061] The pretreated coal, melamine and potassium hydroxide were weighed at a mass ratio of 1:4:2, ground and mixed, transferred to a tube furnace, and heated at 3 °C for min under a nitrogen atmosphere. –1 The heating rate was carbonized at 900 °C for 2 h, and after the carbonization was completed, it was taken out, pickled, filtered, washed with water, and dried to obtain nitrogen-doped carbon N 4 C-900; Nitrogen-doped carbon and phosphoric acid were weighed at a mass ratio of 1:4, diluted with water and mixed ultrasonically. The specific ultrasonic parameters were 25 Hz (5 min), 33 Hz (10 min), 40 Hz (5 min) , 59Hz (10 min), total time 0.5 h, post-dried and transferred to tube furnace, 3 ℃ min under nitrogen atmosphere –1 The heating rate was carbonized at 900 ℃ for 1 h to obtain the secondary carbonized product; the secondary carbonized product was mixed with 1 mol L –1 Pickle with dilute hydrochloric acid solution for 1-3 h, filter, wash with water until the filtrate is...

Embodiment 3

[0063] The pretreated coal, melamine and potassium hydroxide were weighed at a mass ratio of 1:4:2, ground and mixed, transferred to a tube furnace, and heated at 3 °C for min under a nitrogen atmosphere. –1 The heating rate was carbonized at 900 °C for 2 h, and after the carbonization was completed, it was taken out, pickled, filtered, washed with water, and dried to obtain nitrogen-doped carbon N 4 C-900; Weigh nitrogen-doped carbon and phosphoric acid according to the mass ratio of 1:4, mix them directly, dry them and transfer them to a tube furnace. –1 The heating rate was carbonized at 900 ℃ for 1 h to obtain the secondary carbonized product; the secondary carbonized product was mixed with 1 mol L –1 Pickle with dilute hydrochloric acid solution for 1-3 h, filter, wash with water until the filtrate is neutral, and dry to obtain nitrogen and phosphorus doped porous carbon material N 4 P 4 C-900-d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com