Method for grinding a bevel gear

A bevel gear, grinding technology, applied in the direction of grinding machine parts, components with teeth, gear tooth manufacturing devices, etc., can solve the problems of reduced machining accuracy, time-consuming, etc. The effect of conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

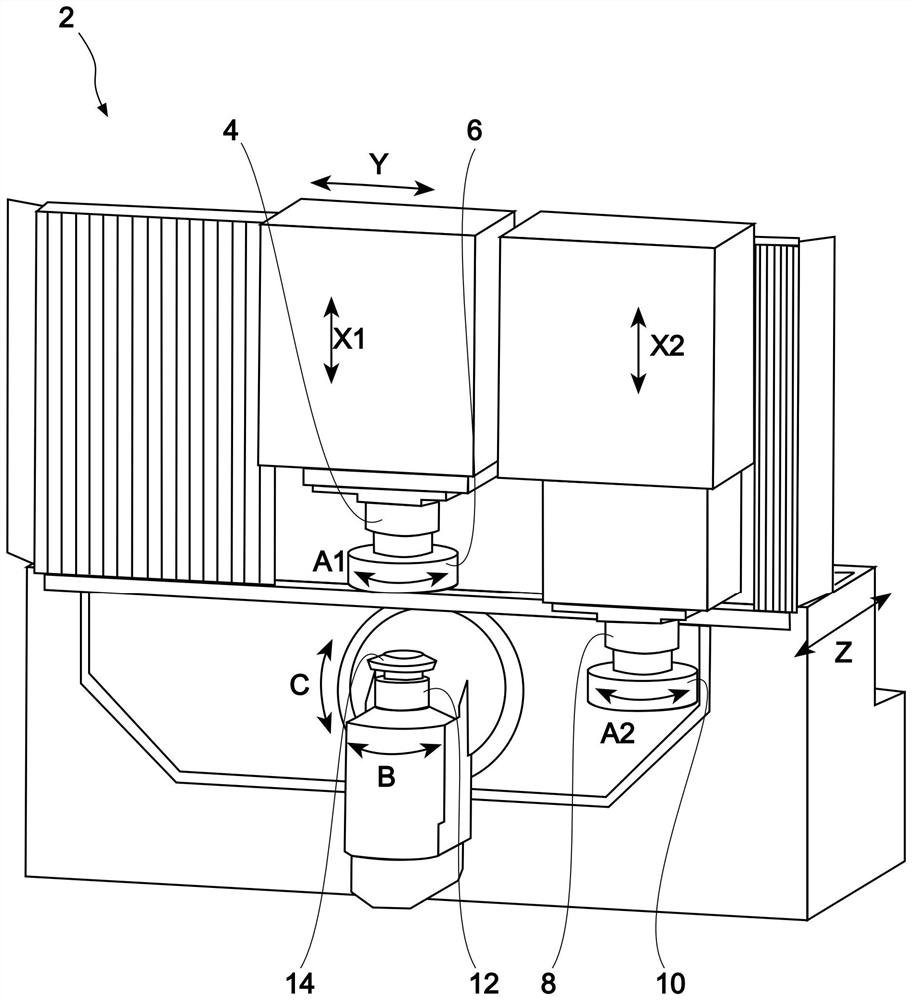

[0058] figure 1 A twin-spindle machine tool 2 is shown, which is a bevel gear grinding machine 2 . The twin-spindle machine tool 2 has a first tool spindle 4 . A first grinding tool 6 is fastened to the first tool spindle 4 . The twin-spindle machine tool 2 has a second tool spindle 8 . A second grinding tool 10 is fastened to the second tool spindle 8 .

[0059] The first tool spindle 4 is designed to drive a first grinding tool 6 in rotation (axis of rotation A1 ). The first tool spindle 4 is movable in translation along the axes X1, Y and Z, respectively.

[0060] The second tool spindle 8 is designed to drive a second grinding tool 10 in rotation (axis of rotation A2 ). The second tool spindle 8 is movable in translation along the axes X2, Y and Z, respectively.

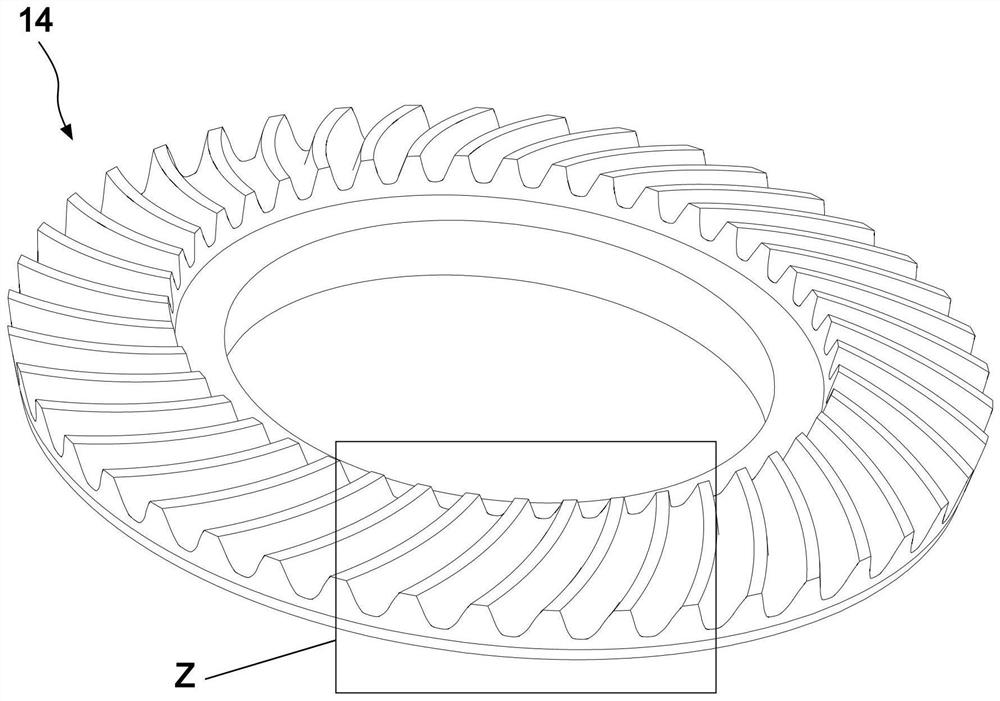

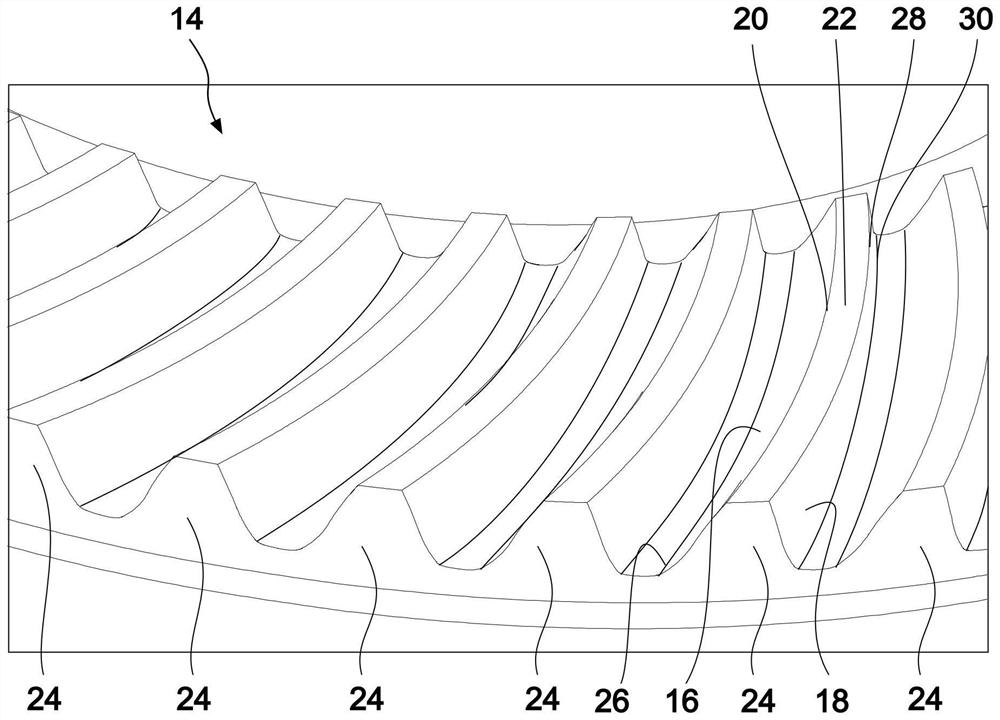

[0061] A pre-toothed and hardened bevel gear 14 or bevel gear workpiece 14 is fastened to the workpiece spindle 12 of the twin-spindle machine tool 2 . The terms bevel gear and bevel gear workpiece are use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com