Irradiation sterilization method of seasoning powder

A technology for irradiation sterilization and seasoning powder, which is applied in the fields of food science, food preservation, application, etc., can solve the problems of in-depth research on the method of irradiation sterilization of seasoning powder, and achieves that the method of irradiation sterilization is simple and easy to implement and improves the consumption of food. Safety, efficacy in preventing and treating chronic diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

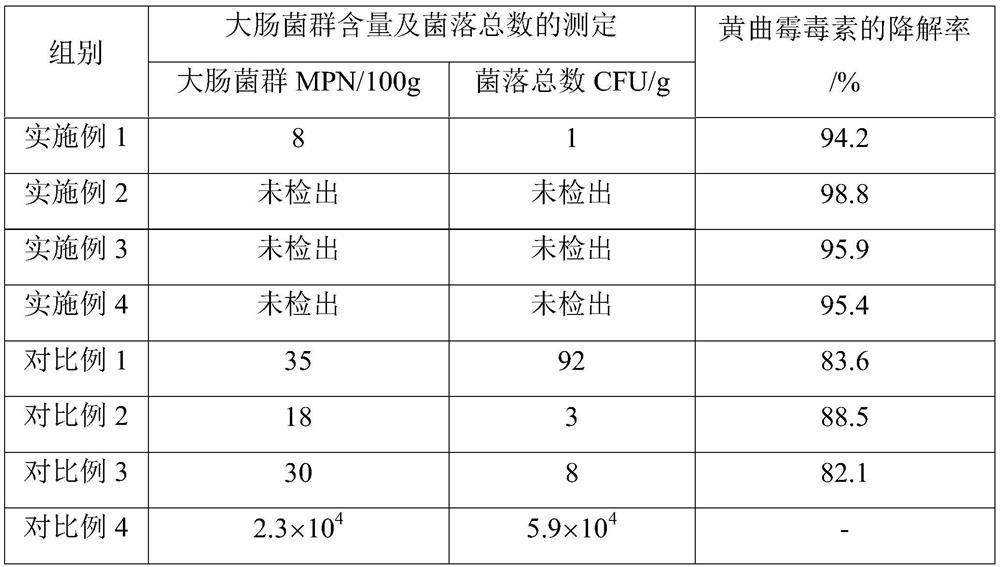

Examples

Embodiment 1

[0027] Embodiment 1, a kind of radiation sterilization method of seasoning powder

[0028] Include the following steps:

[0029] S1) Add carboxymethyl chitosan, glycyrrhizin, and seasoning powder to purified water that is 3 times the total mass of the claimed material in turn, mix them, and homogenize under high pressure at 25 MPa for 1 min, spray dry, the inlet temperature of spray drying is 85 ° C, and the outlet The temperature is 50°C, the feeding speed is 8rpm, and the mixed powder is obtained;

[0030] S2) Put the mixed powder in step S1 into a polyethylene packaging bag, vacuumize, then fill the packaging bag with nitrogen, and seal it by thermoplastic method to obtain the pretreated mixed powder;

[0031] S3) Put the pretreated mixed powder of step S1 in the center of the tray, then place the tray on the circulation car, turn on the electron beam accelerator for irradiation treatment for 20 minutes, the irradiation dose is 6kGy, and the irradiation thickness is 10cm. ...

Embodiment 2

[0033] Embodiment 2, a kind of radiation sterilization method of seasoning powder

[0034] Include the following steps:

[0035] S1) Add carboxymethyl chitosan, glycyrrhizin, and flavoring powder to the purified water which is 3 times the total mass of the claimed material in turn, mix them, homogenize under high pressure at 30MPa for 1min, spray dry, the inlet temperature of spray drying is 85°C, and the outlet The temperature is 50°C, the feeding speed is 8rpm, and the mixed powder is obtained;

[0036] S2) Put the mixed powder in step S1 into a polyethylene packaging bag, vacuumize, then fill the packaging bag with nitrogen, and seal it by thermoplastic method to obtain the pretreated mixed powder;

[0037] S3) Put the pretreatment mixed powder of step S1 in the center of the tray, then place the tray on the circulation car, turn on the electron beam accelerator for irradiation treatment for 25min, the irradiation dose is 6kGy, and the irradiation thickness is 10cm. The e...

Embodiment 3

[0039] Embodiment 3, a kind of radiation sterilization method of seasoning powder

[0040] Include the following steps:

[0041] S1) Add carboxymethyl chitosan, glycyrrhizin, and seasoning powder to purified water that is 3 times the total mass of the material in turn, mix them, and homogenize under high pressure at 25 MPa for 1 min, then spray dry. The inlet temperature of spray drying is 90°C, and the outlet The temperature is 45°C, the feeding speed is 10rpm, and the mixed powder is obtained;

[0042] S2) Put the mixed powder in step S1 into a polyethylene packaging bag, vacuumize, then fill the packaging bag with nitrogen, and seal it by thermoplastic method to obtain the pretreated mixed powder;

[0043] S3) Put the pretreatment mixed powder of step S1 in the center of the tray, then place the tray on the circulation car, turn on the electron beam accelerator for irradiation treatment for 20 minutes, the irradiation dose is 7kGy, and the irradiation thickness is 10cm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com