Galvanic pile box body and manufacturing method thereof

A manufacturing method and box technology, applied in the field of electric stack boxes, can solve the problems of low efficiency and high cost of additional support devices, and achieve the effect of solving troublesome disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

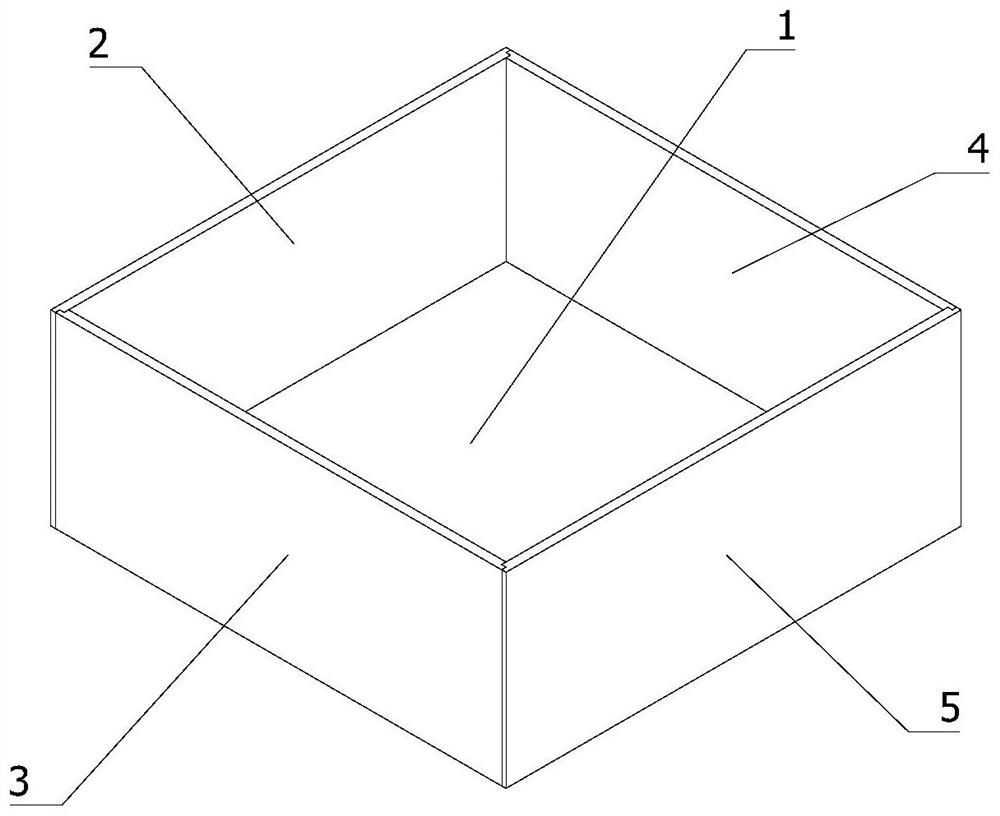

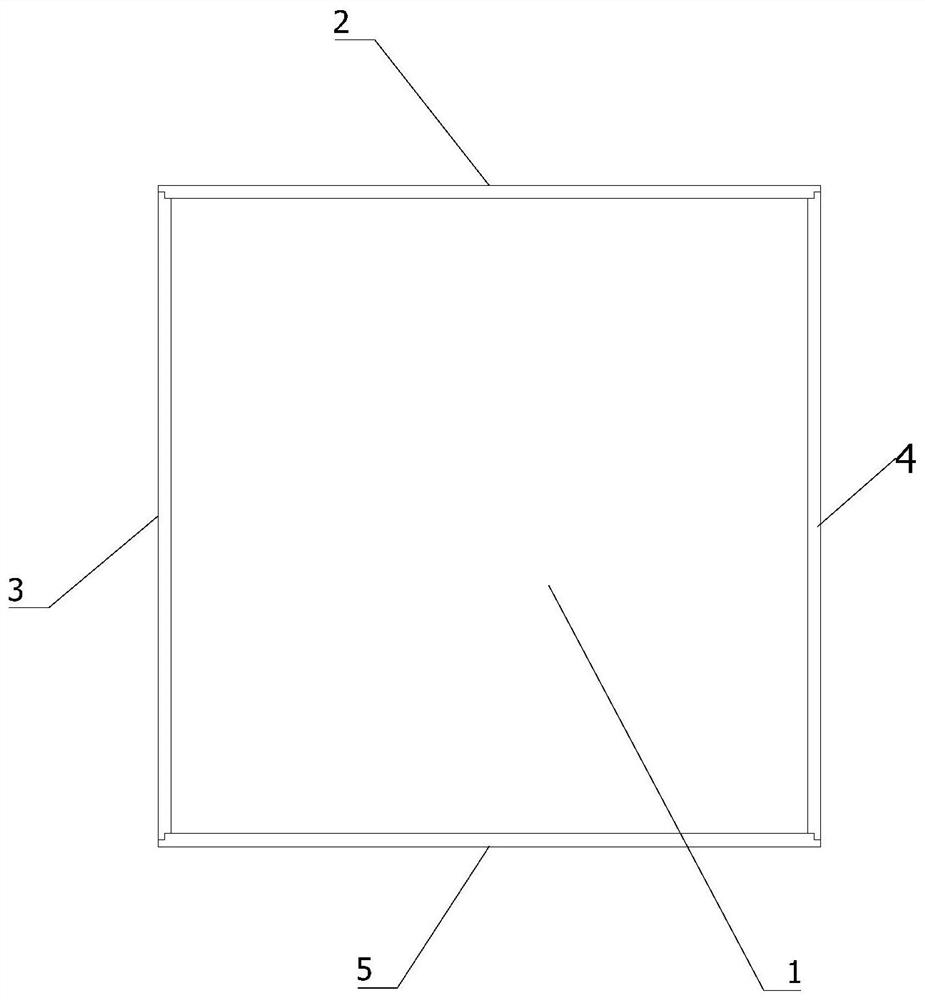

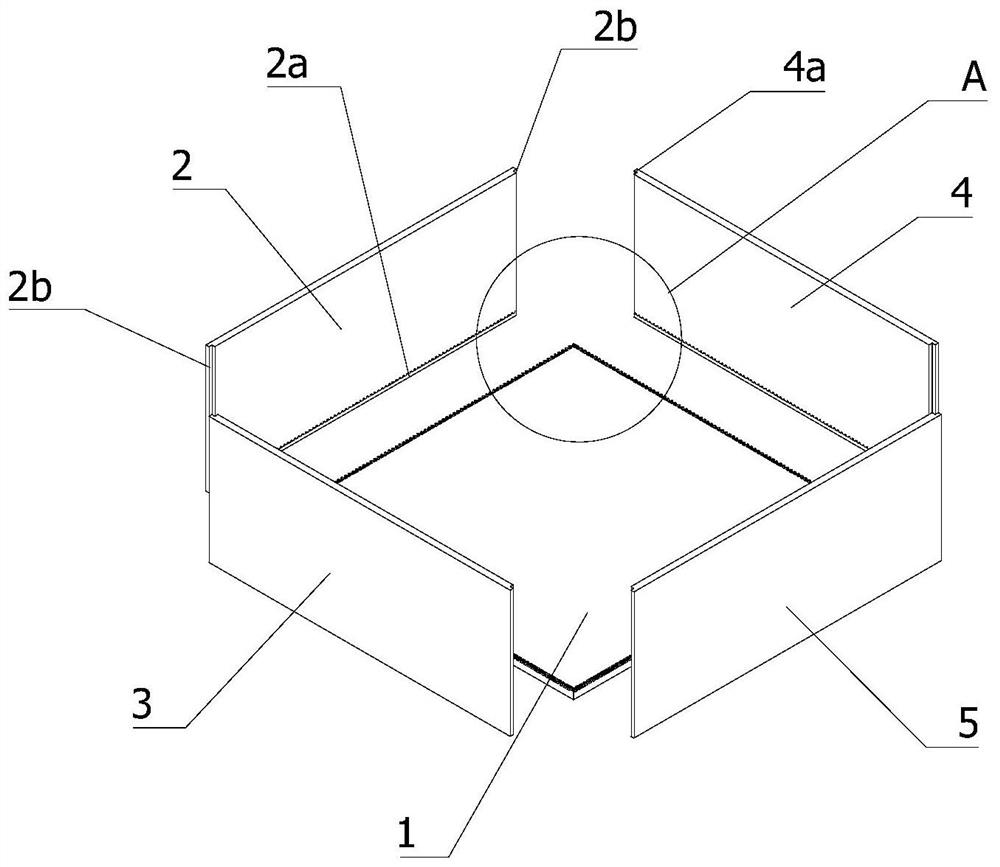

[0053] Such as Figure 1-7 As shown, the present embodiment provides a stack box, the stack box is an aluminum alloy stack box, which includes a bottom plate 1, and two pairs of side plates facing each other, a front plate 2 and a rear plate 5, The left side plate 3 and the right side plate 4, the above-mentioned side plates and bottom plates are all aluminum alloy plate bodies, the advantages of aluminum alloy are light weight, high strength, and easy to process; wherein, the bottom plate is a rectangular plate arranged horizontally, and each side plate is respectively Vertically arranged rectangular boards; preferably, each pair of side boards has a first step structure on both side edges, that is, respectively includes a first step structure 2b of the front board, a first step structure 3a of the left side board, and a first step structure 3a of the right side board. The first stepped structure 4a of the side plate and the first stepped structure 5a of the rear plate; the t...

Embodiment 2

[0075] This embodiment provides an aluminum alloy stack box, which differs from the stack box provided in Example 1 in that only the two side edges of the pair of side plates have a first stepped structure, and the two sides of the two pairs of side plates have a first stepped structure. The side edges are clamped to each other, specifically, the pair of side plates that do not have the first step structure on the edge are clamped into the first step structure embedded in the two side edges of the other pair of side plates, and there is a weld at the joint; The bottom edges of the two pairs of side plates all have a second step structure, and the second step structure is respectively clamped on the edge of the bottom plate, and there is a weld at the joint; it can be understood that the edge does not have the first step structure. The bottom edge of the pair of side plates is the same as the length of the first step structure snapped into the two side edges of the other pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com