Novel HIT and EB material matched organic light-emitting device

An electroluminescent device and electroluminescent technology, applied in the field of semiconductors, can solve the problems of large HOMO energy level difference, affecting device performance, affecting device life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

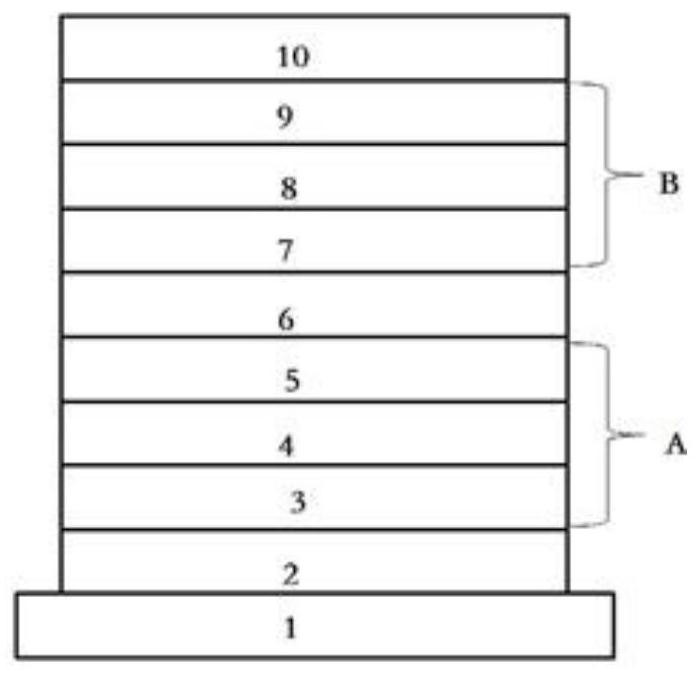

[0109] Hole injection layer 1: Use the OLED Chuster Deposition System (manufacturer: CHOSHU INDUSTRY Co.LTD.) evaporation equipment of model 1504-10117-01-0 to place the hole transport host material HI1 and the P-type dopant material P1 on the Two evaporation sources, at a vacuum degree of 1.0E -5 Under Pa pressure, control the evaporation rate of HIT1 as Control the evaporation rate of P-type dopant material 1 as Co-distilled together to obtain HI1 of the present invention.

[0110] Hole injection layer 2: repeat the preparation process of hole injection layer preparation example 1, the difference is that HIT1 is replaced by HIT3 to obtain HI2.

[0111] Hole injection layer 3: Repeat the preparation process of hole injection layer preparation example 1, except that HIT1 is replaced by HIT11 to obtain HI3.

[0112] Hole injection layer 4: Repeat the preparation process of hole injection layer preparation example 1, except that HIT1 is replaced by HIT15 to obtain HI4.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com