Sandwich structure heat dissipation film based on graphene, semiconductor device and preparation method thereof

A technology of graphene film and heat dissipation film, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., to achieve good heat dissipation effect, ensure service performance and life, and the effect of easy implementation of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 1) The preparation process of CVD graphene is as follows:

[0039] Remove the oxides on the surface of the metal substrate, wash and dry it, put it into a growth furnace, feed methane and hydrogen, and grow in the temperature range of 1000°C-1300°C for 30-60 minutes to obtain CVD graphene.

[0040] 2) Preparation of redox graphene

[0041] Take 1-2 mg of graphene oxide, put it into 10 ml of deionized water and shake it for 10-60 minutes, and then sonicate for 4-24 hours to obtain a uniformly dispersed graphene oxide dispersion. Graphene oxide is reduced by a reducing agent to obtain redox graphene.

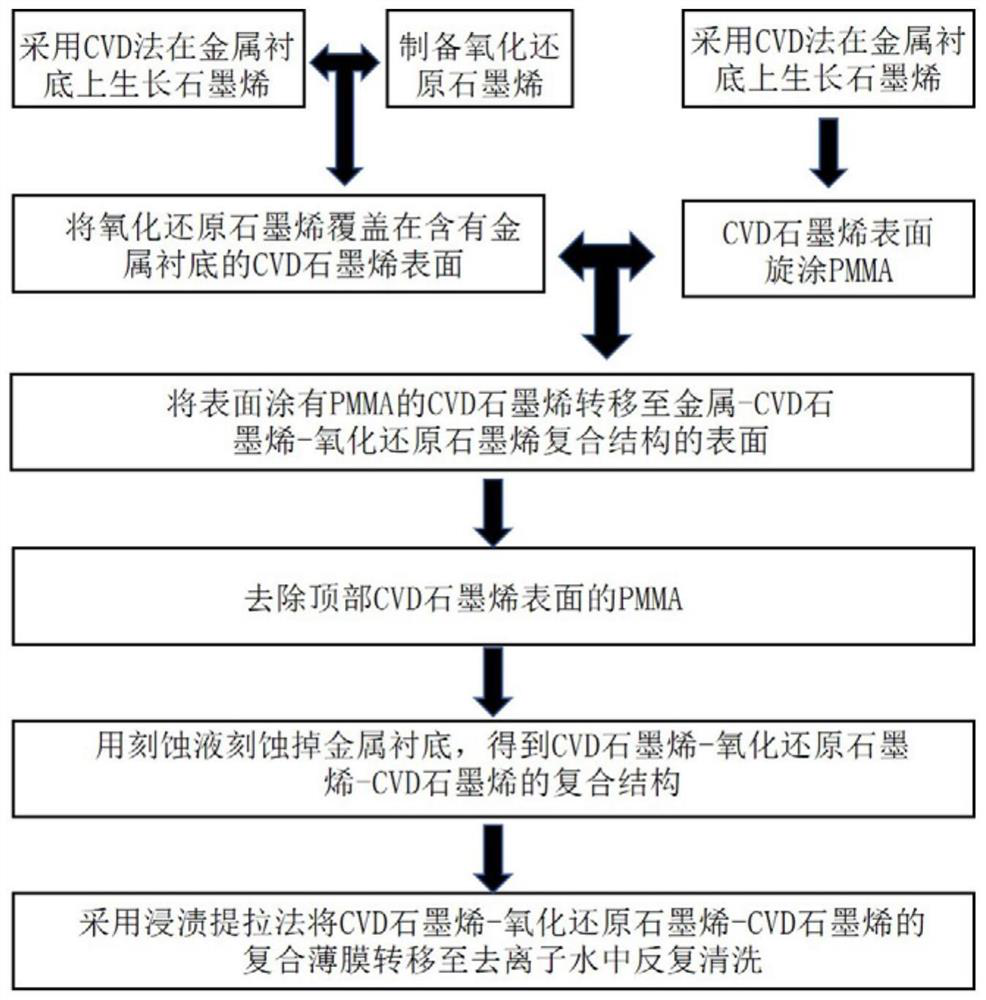

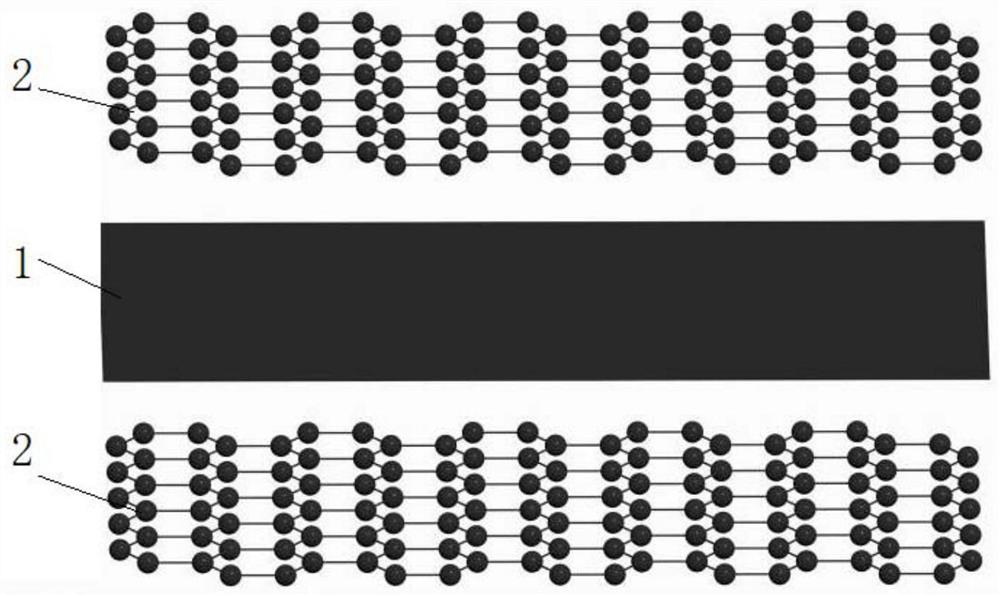

[0042]3) Preparation of sandwich structure composite film

[0043] 3.1) Covered redox graphene

[0044] Structure B was obtained by covering a layer of redox graphene on CVD graphene with a metal substrate. Among them, to cover the redox graphene on the CVD graphene, it is necessary to ensure the flatness and uniformity of the redox graphite. If the flatness of the fil...

Embodiment 1

[0050] The present embodiment prepares the method for the sandwich structure heat dissipation film based on graphene, comprises the following steps:

[0051] 1) Preparation of CVD graphene:

[0052] Clean the copper foil with ethanol, hydrochloric acid and deionized water to remove oxides on the surface, dry it and put it into the growth furnace. CVD graphene was obtained by feeding methane and hydrogen, and growing at 1200° C. for 60 minutes.

[0053] 2) Preparation of redox graphene

[0054] Take 1 mg of graphene oxide, put it into 10 ml of deionized water and shake it for 60 minutes, and then sonicate it for 4 hours to obtain a uniformly dispersed graphene oxide dispersion. Graphene oxide was reduced by hydrazine hydrate to obtain redox graphene.

[0055] 3) Preparation of sandwich structure composite film

[0056] 3.1) Covered redox graphene

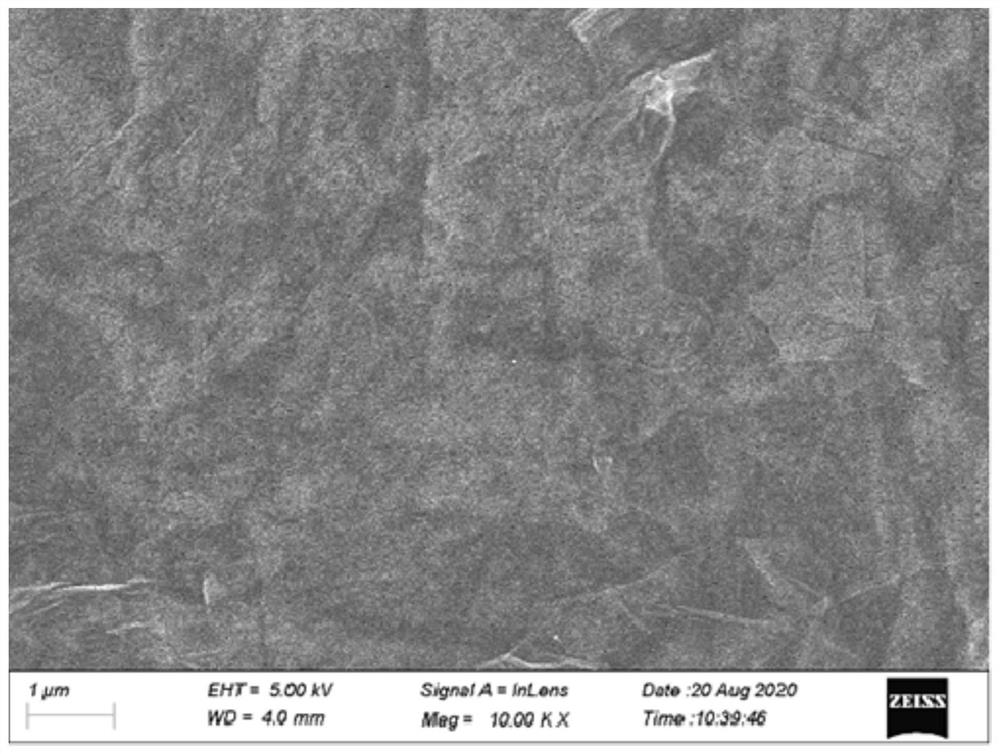

[0057] A layer of redox graphene was spin-coated on the surface of CVD graphene on copper foil at a rotation speed of 500-1500...

Embodiment 2

[0067] The present embodiment prepares the method for the sandwich structure heat dissipation film based on graphene, comprises the following steps:

[0068] 1) Preparation of CVD graphene:

[0069] Clean the copper foil with ethanol, hydrochloric acid and deionized water to remove oxides on the surface, dry it and put it into the growth furnace. CVD graphene was obtained by feeding methane and hydrogen, and growing at 1200° C. for 60 minutes.

[0070] 2) Preparation of redox graphene

[0071] Take 1.5 mg of graphene oxide, put it into 10 ml of deionized water and shake it for 60 minutes, and then sonicate it for 4 hours to obtain a uniformly dispersed graphene oxide dispersion. Graphene oxide was reduced by hydrazine hydrate to obtain redox graphene.

[0072] 3) Preparation of sandwich structure composite film

[0073] 3.1) Covered redox graphene

[0074] A layer of graphene oxide is spin-coated on the surface of CVD graphene on copper foil at a speed of 1000 rpm. of mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com