Ultra-high performance liquid chromatography detection method for mannose in honey

An ultra-high performance liquid chromatography and chromatographic detection technology is applied in the field of ultra-high performance liquid chromatography detection of mannose in honey, and achieves the effects of high efficiency, increased pretreatment difficulty and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

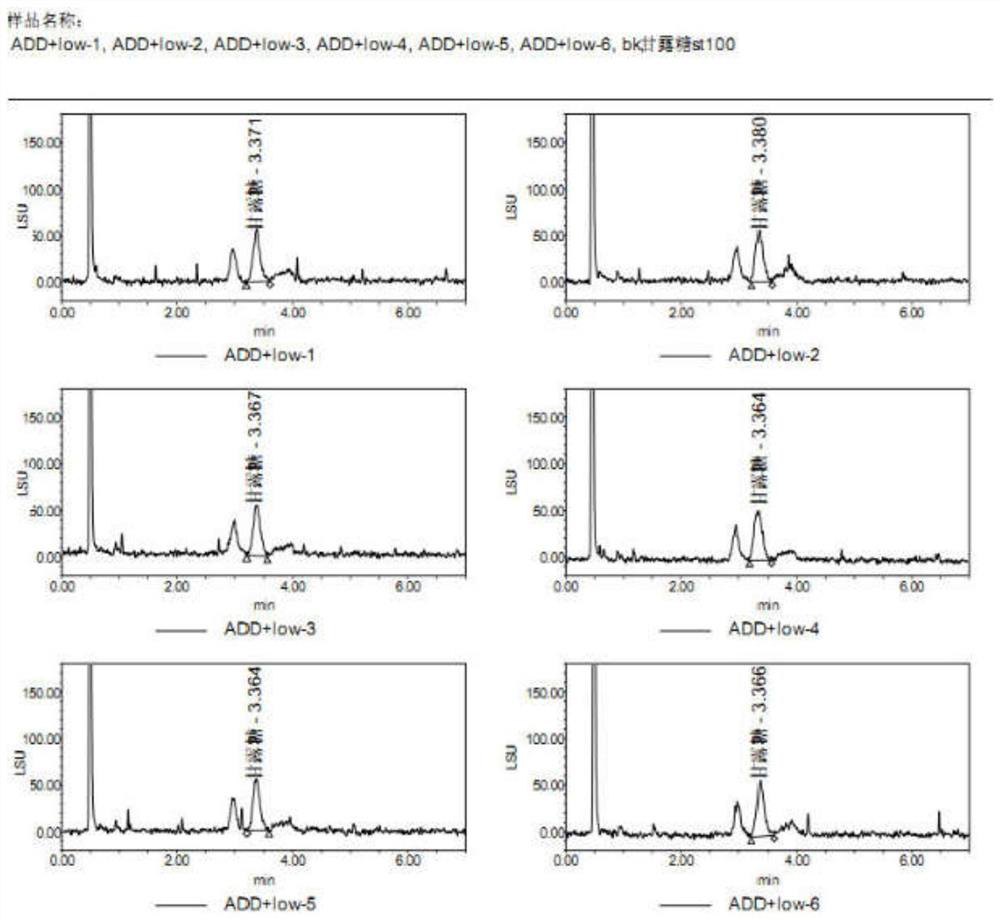

Examples

Embodiment 1

[0041] An ultra-high performance liquid chromatography detection method for mannose in honey, said method comprising:

[0042] 1. Instruments and reagents

[0043] Ultra-high performance liquid chromatography; American Waters-I-class UPLC equipped with evaporative light scattering detector detection;

[0044] Standard substance: mannose, purity 99.6%

[0045] Acetonitrile: chromatographically pure;

[0046] Triethylamine: chromatographically pure;

[0047] The water used in this method is primary water.

[0048]2. Liquid chromatography conditions:

[0049] Column: Waters ACQUITY BEH Amide 1.7μm 2.3×100mm

[0050] Mobile phase: 0.2% ETA acetonitrile solution + water = 84 + 16

[0051] Evaporative photodetector conditions: gain: 200; drift tube temperature: 65°C; carrier gas pressure: 30psi;

[0052] Column temperature: 35°C

[0053] Flow rate: 0.3mL / min

[0054] Injection volume: 3μL

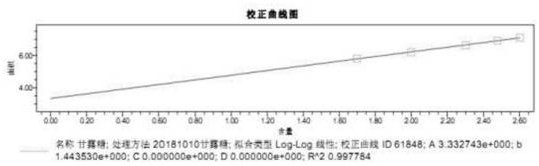

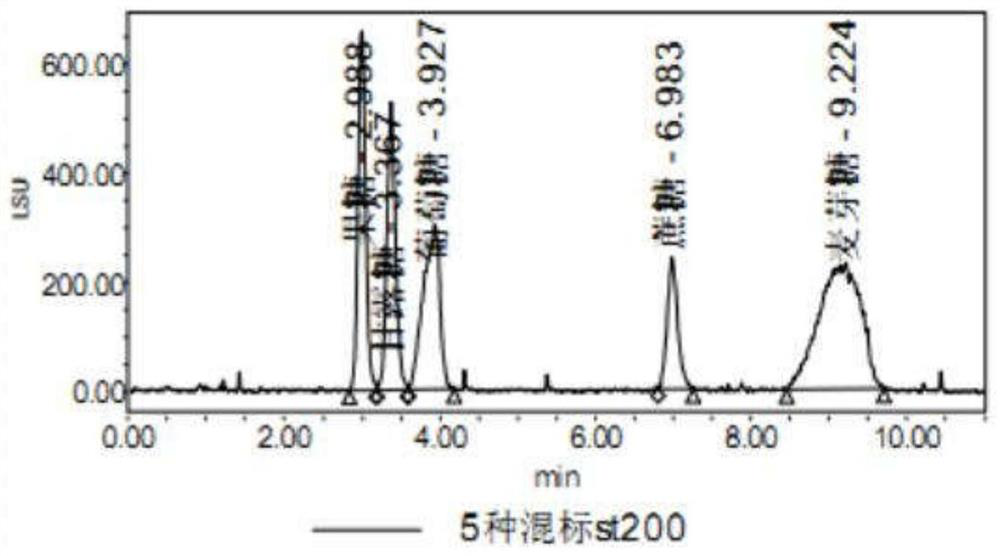

[0055] 3. Linear equation and standard chromatogram

[0056] Standard stock solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com