Fabricated house stable in structure

A prefabricated and stable technology, applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve the problems of insufficient assembly stability and difficulty in popularization and application, and achieve enhanced stability, guaranteed stability, and reduced vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

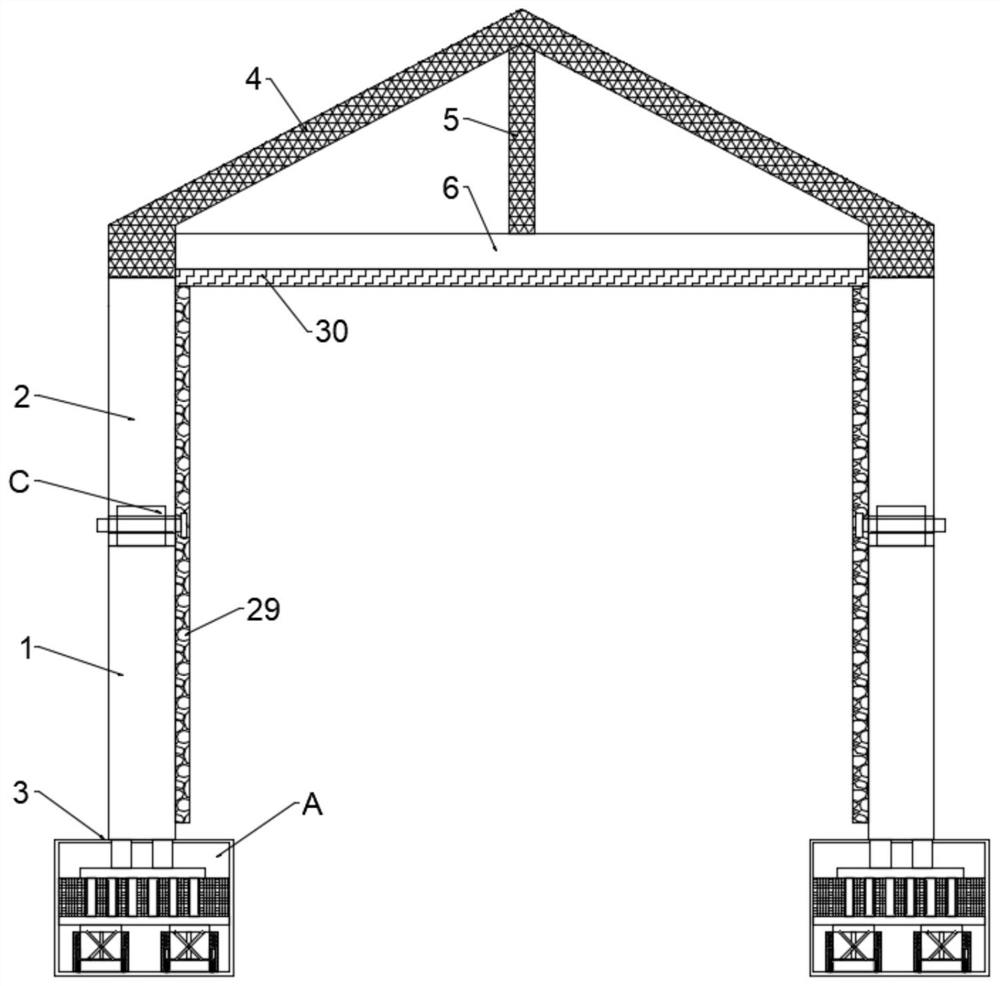

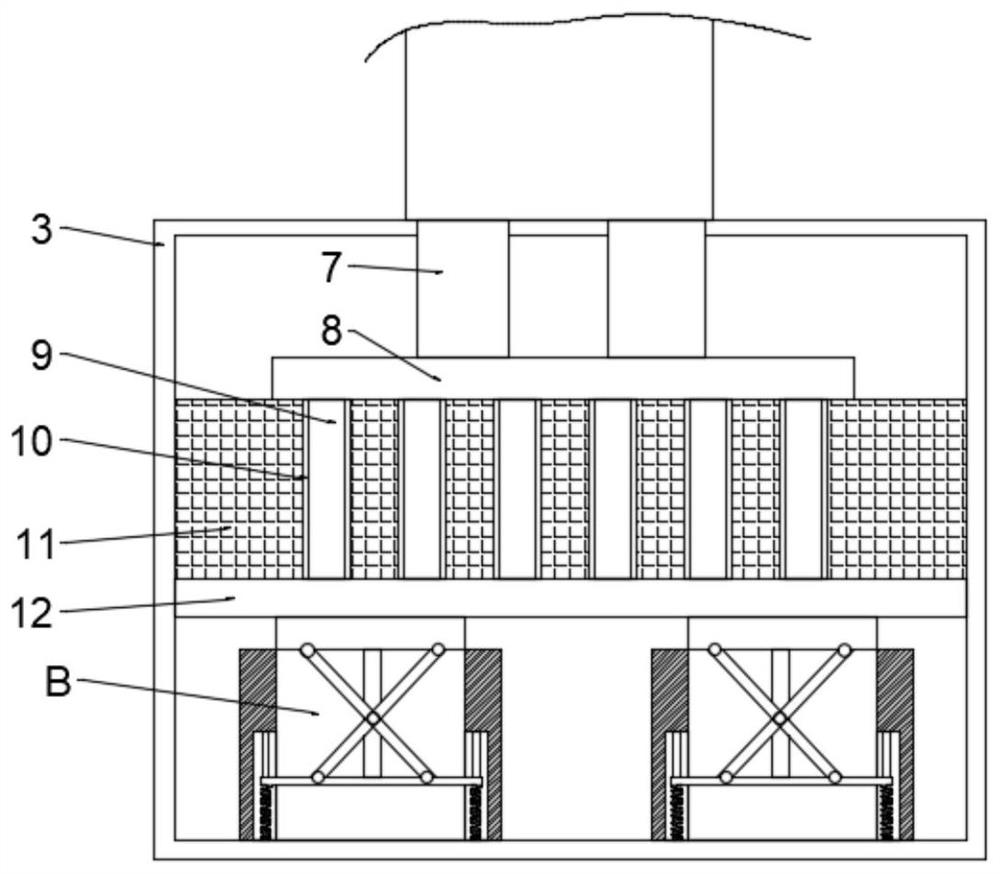

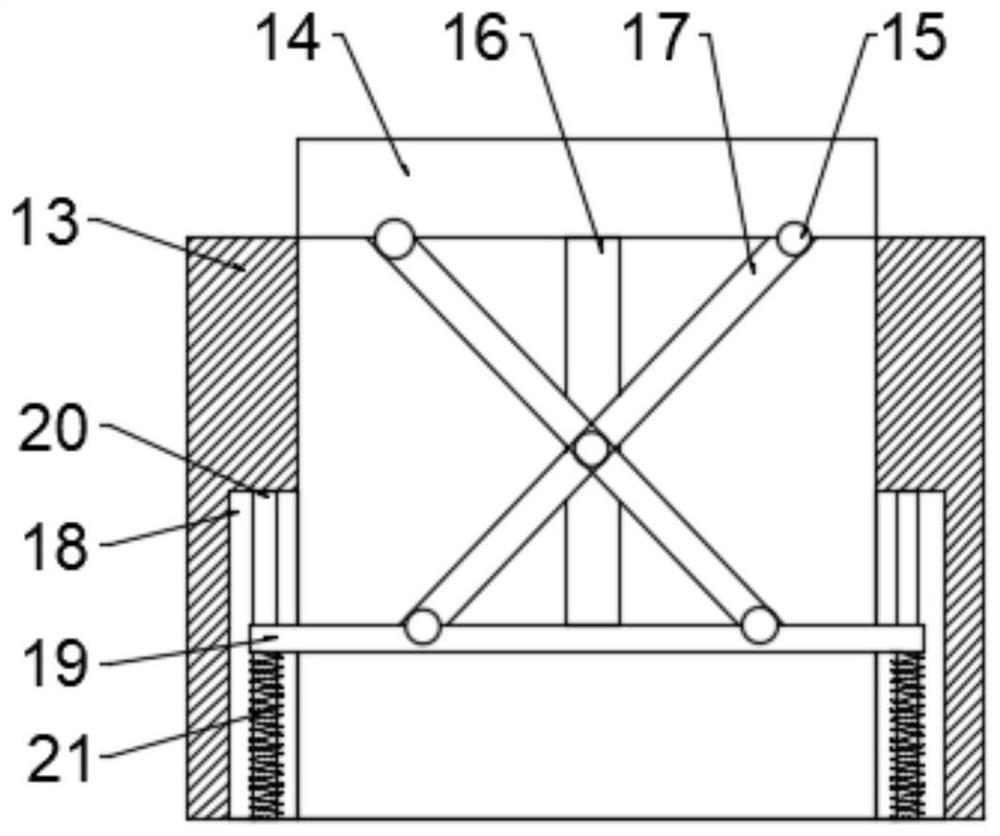

[0030] See Figure 1 ~ 5 A stable assembly house, including the first pillar 1, the first strut 1 fixed to the connecting card 22, which is disposed in the limit slot 23, the limit slot 23 is disposed Next, the second pillar 2 is fixedly coupled to the first pillar 1, the second strut 2 fixedly connected to the top 4 of the first pillar 1, the first pillar 1 and the second pillar 2 about the room The top 4 is configured, and the beam 6 is disposed below 4, and the cross member 6 is fixed to the second pillar 2, and the block 22 is provided with a through hole 24, the through hole 24 runs through the second The strut 2, the block 22 and the limit slot 23 are provided with an expansion screw 25, and the first strut 1 is provided with a mounting base 3, and the device can be better secured by mounting the base 3. The stability between the first struts 1 and the second pillar 2 connection can be enhanced by the expansion screw 25, and the device is prevented from shaking.

[0031] The...

Embodiment 2

[0037] See Figure 1 ~ 7 A stable assembly house, including the first pillar 1, further comprising the second card slot 31 and a fixed block 32, the first strut 1 fixed to the connecting block 22, and the block 22 is set to limit Inside the groove 23, the limit slot 23 is disposed below the second pillar 2, the second strut 2 fixed to the first strut 1, the second strut 2 away from the first pillar 1 fixed connection to the roof 4, The first strut 1 and the second strut 2 are arranged in respective symmetry of the top 4 left and right, and the top 4 is provided with a beam 6, and the beam 6 is fixed to the second pillar 2, and the block 22 is provided. The through hole 24, the through hole 24 runs through the second pillar 2, the block 22, and the limit slot 23, the through hole 24, which is provided with an expansion screw 25, and the first pillar 1 is provided with a mounting base 3, passed The mounting base 3 can fix the device better, and the stability between the first struts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com