Pull rod type multipurpose steel trestle abutment and construction method thereof

A construction method and multi-purpose technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of complex concrete stress, difficulty in demolition, high cost, etc., achieve high-quality and stable design and construction, and small subsequent settlement , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

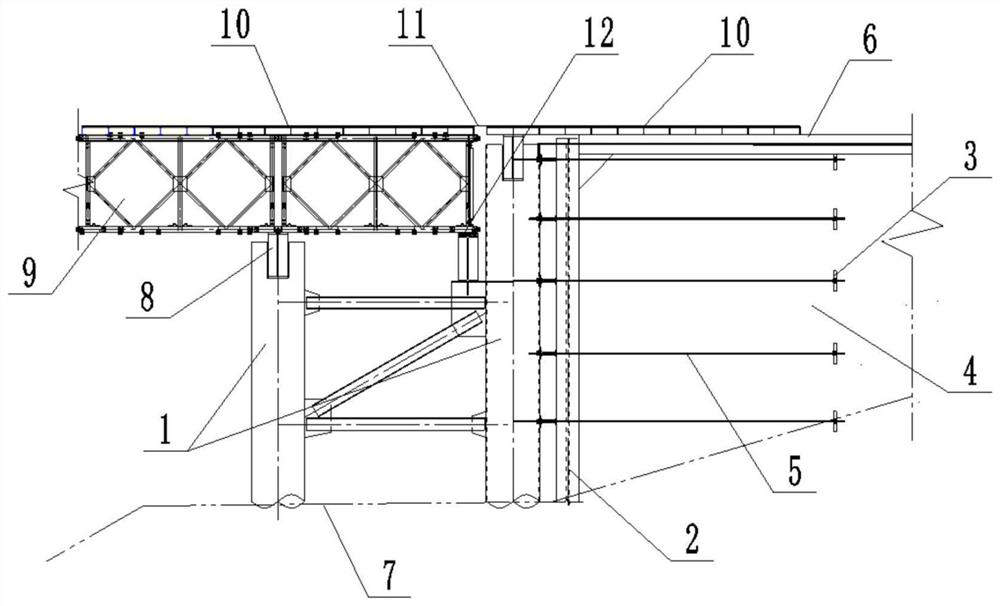

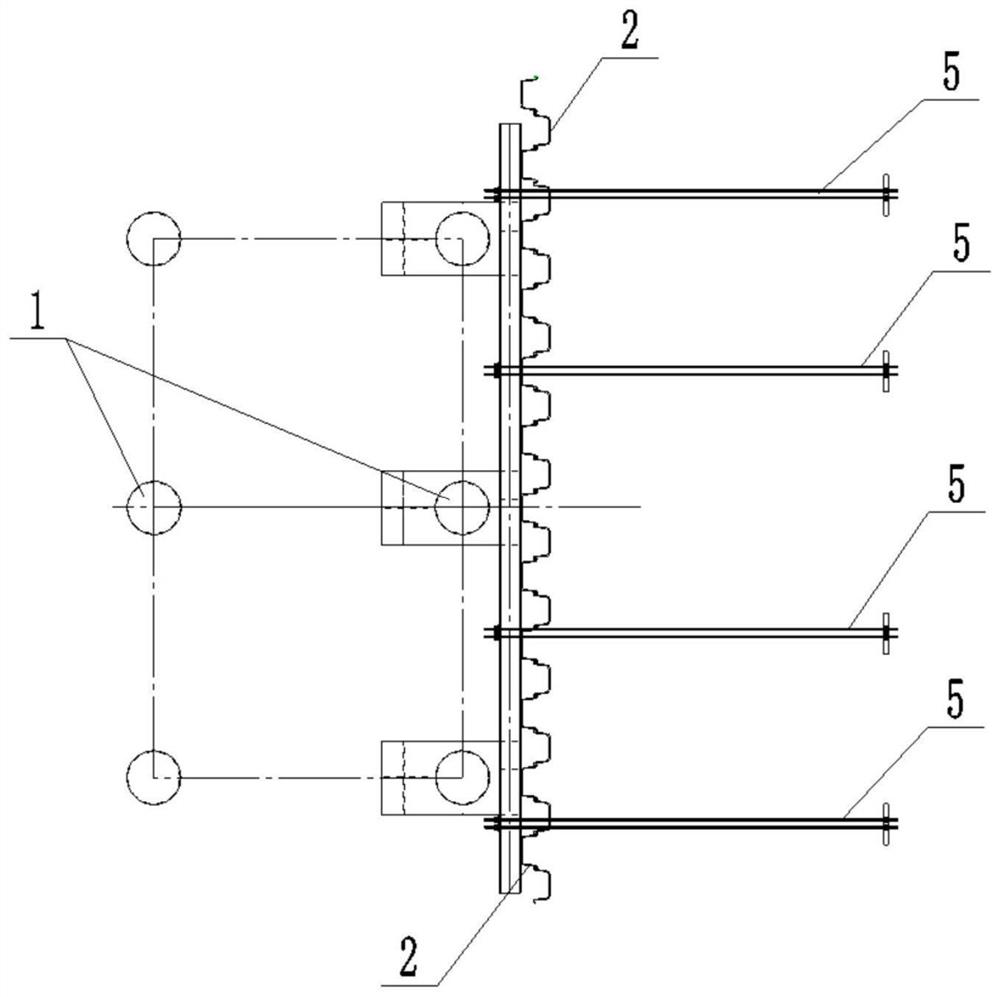

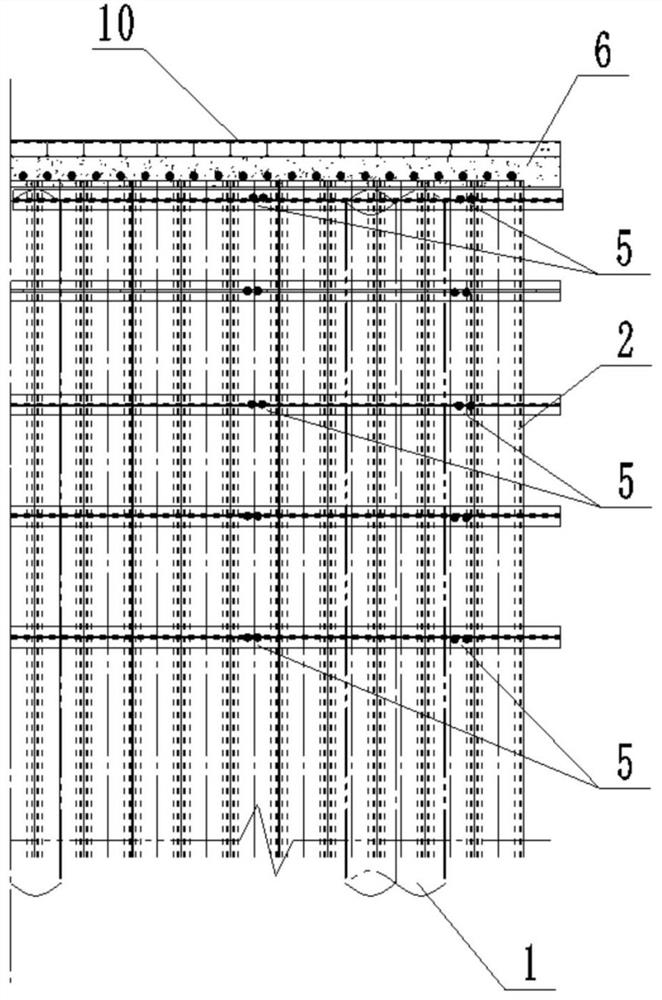

[0022] Such as Figure 1 to Figure 3 As shown, it is a schematic diagram of the longitudinal section, lower plane and 1 / 2 longitudinal section of a pull-rod type multi-purpose steel trestle abutment of the present invention, including double-row steel pipe piles 1, soil retaining steel sheet piles 2, reverse tension steel sheets 3, Abutment back filler 4, pull screw 5 and abutment strapping plate 6.

[0023] The double-row steel pipe pile 1 is a double-row steel pipe pile 13 with a spacing of 3m set according to the width of the trestle bridge. Round steel pipes or I-beams are arranged between the steel pipe piles 13 as the double-row steel pipe pile connection system 14, and the interior is filled with fine sand. Or concrete to enhance its rigidity and lateral stability, such as Figure 4 As shown, it is a detailed schematic diagram of the overlapping platform of the steel pipe pile 13 of the present invention.

[0024] The soil retaining steel sheet pile 2 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com