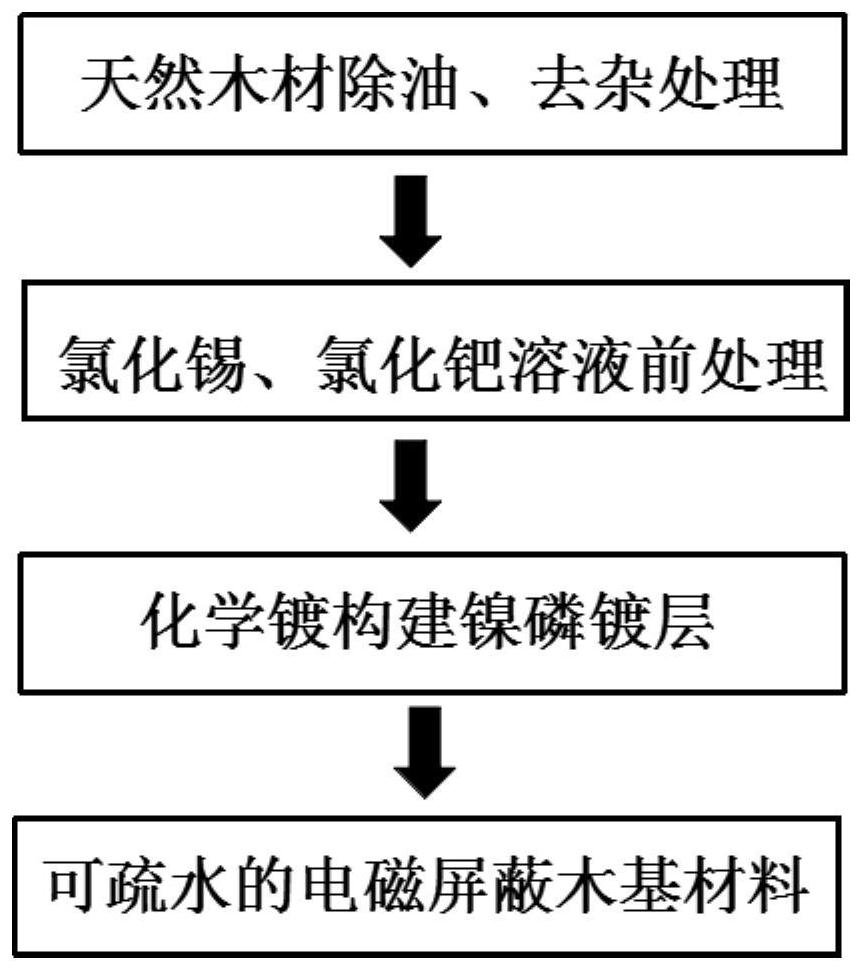

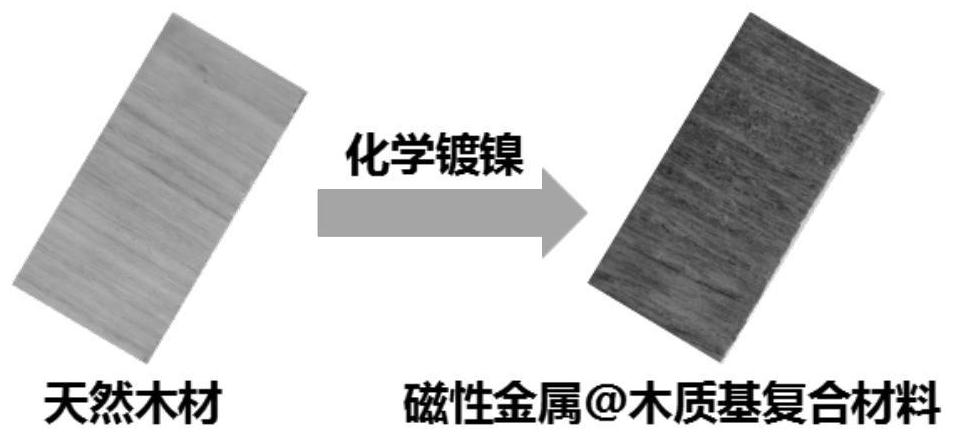

Preparation process of electromagnetic shielding material for constructing hydrophobic coating on the surface of wood-based materials

A technology of electromagnetic shielding materials and hydrophobic coatings, which is applied in metal material coating technology, magnetic field/electric field shielding, coatings, etc., can solve the problems of reducing the magnetic properties of chemical coatings, unsuitability, and poor bonding of wood substrates to achieve high-efficiency electromagnetic coatings. Effects of shielding properties, simple operation, and excellent superhydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

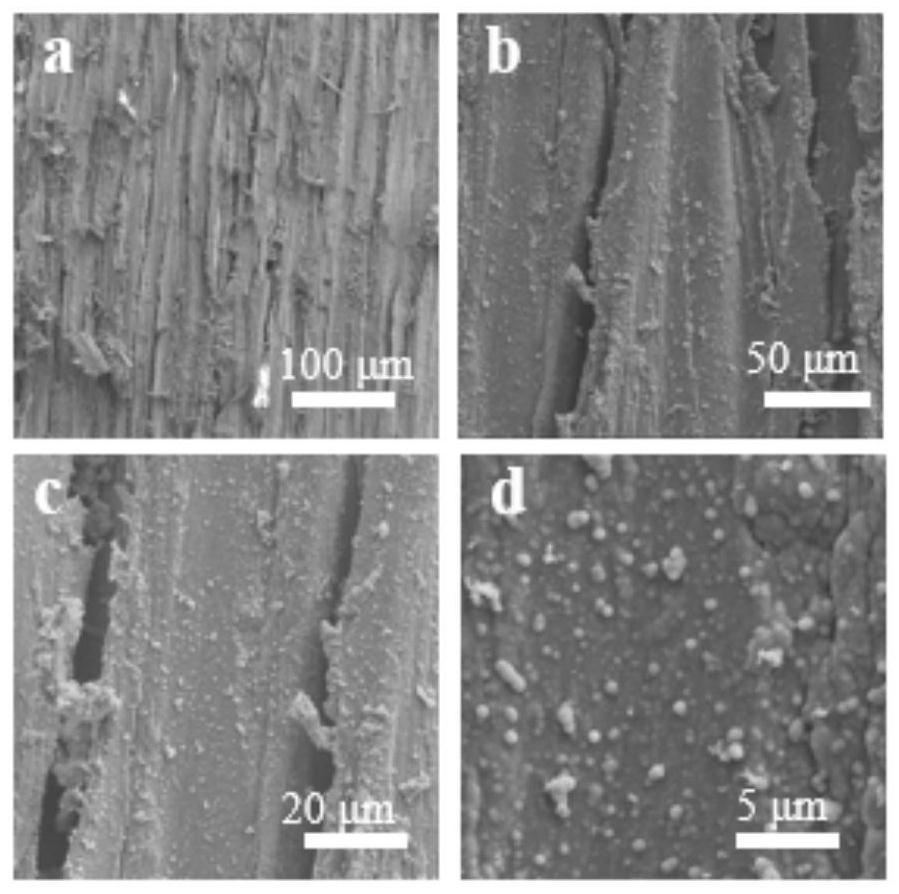

Embodiment 1

[0033] Step 1: Cut paulownia wood chips with a thickness of about 1.5mm into 50cm×50cm and place them in a drying oven, and dry them at 100°C for 24 hours to remove all moisture. Thereafter, the prepared wood was placed in an ethanol solution for ultrasonic treatment for 20 minutes, and then placed in an ultrapure aqueous solution at about 60 ° C for 20 minutes, so that it was treated three times alternately.

[0034] Step 2: Place the pretreated wood in the configured sensitizing solution (concentration of stannous chloride solution is 20g / L, 30% dilute hydrochloric acid 12mL / L), sensitize for 10min, and then use deionized water repeatedly Rinse for about 10 minutes.

[0035] Step 3: Place the sensitized wood in the prepared activation solution (concentration of palladium chloride solution is 0.5g / L, 30% dilute hydrochloric acid 25mL / L), activate for 10min, and then rinse repeatedly with deionized water About 10 minutes.

[0036] Step 4: Place the activated wood in the 500m...

Embodiment 2

[0040] Step 1: Place the cut 500cm×500×10cm fir block in a drying oven, and dry it at 120°C for 72 hours to remove the adsorbed water.

[0041] Step 2: Dip the dried fir pieces repeatedly in normal temperature ethanol solution and 70°C ultrapure water solution until the cleaning solution no longer has yellow turbid substances overflowing.

[0042] Step 3: Place the fir block through the degreasing treatment in the prepared 200mL sensitization solution (concentration of stannous chloride solution is 15g / L, 30% dilute hydrochloric acid 10mL / L), sensitize for 10min, and then use Rinse with deionized water for about 10 minutes.

[0043] Step 5: Place the sensitized wood in the prepared 200mL activation solution (concentration of palladium chloride solution is 0.3g / L, 30% dilute hydrochloric acid 20mL / L), activate for 10min, then use deionized water repeatedly Rinse for about 10 minutes.

[0044] Step 6: Place the activated wood in 500mL chemical plating solution (green solution)...

Embodiment 3

[0048] Step 1: Place the cut 200cm×200×5cm fir block in a drying oven, and dry it at 120°C for 72 hours to remove the adsorbed water.

[0049] Step 2: Put the dried Chinese fir block into a tube furnace for vacuum carbonization, the heating temperature is 600°C, the heating time is 2h, the heating rate is 5°C / min, and the protective atmosphere is argon.

[0050] Step 3: sensitization and activation are the same as in Example 2.

[0051] Step 4: Place the activated wood in 500mL chemical plating solution (green solution), configure the concentration of nickel sulfate solution to be 30g / L, the concentration of nickel chloride solution to be 60g / L, and the concentration of sodium hypophosphite solution to be 20g / L L, the concentration of sodium citrate solution is 80g / L, and the concentration of ammonium chloride solution is 40g / L. Use a dropper to take an appropriate amount of ammonia water and add it dropwise to the plating solution. The color changes from green to blue. Use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com