Composite mildew-proof silane modified polyether sealant and preparation method and application thereof

A technology of silane-modified polyether and anti-mildew silane, which is applied in the direction of polyether adhesives, adhesives, adhesive types, etc., and can solve the problem of decreased storage stability of rubber materials, poor compatibility of anti-mold agents, and anti-mold time. Short and other problems, to achieve the effect of improving mechanical properties, excellent mechanical properties, shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

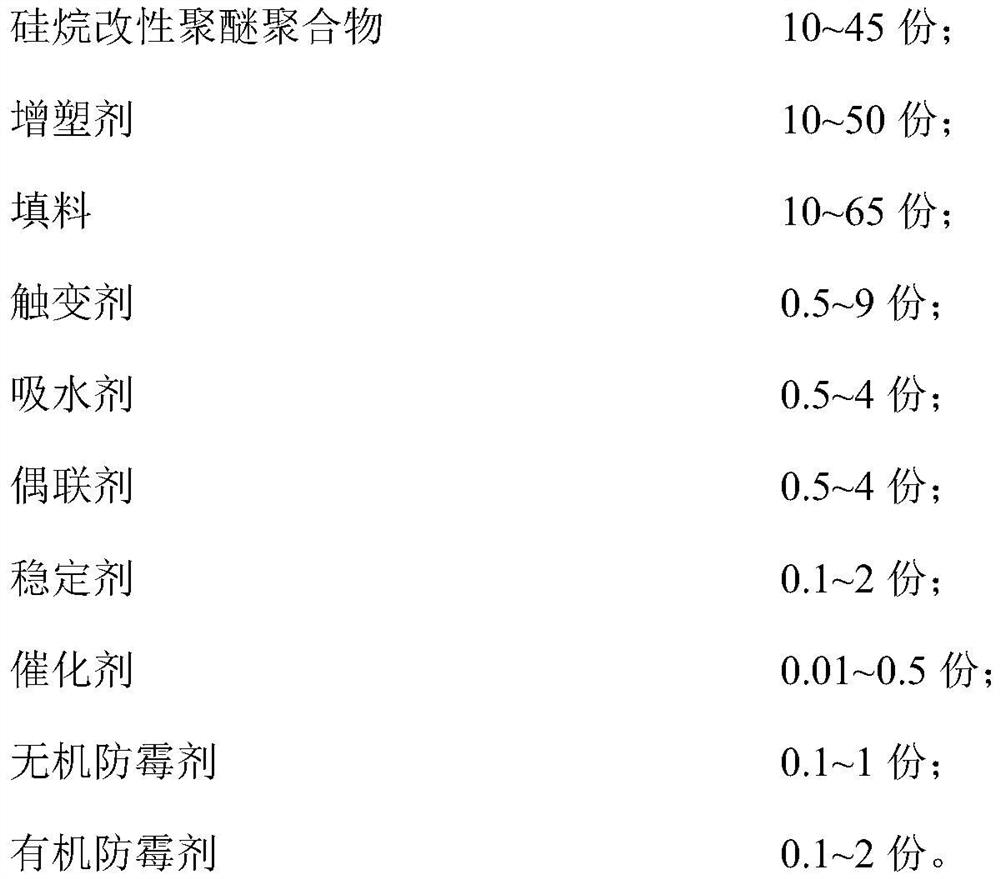

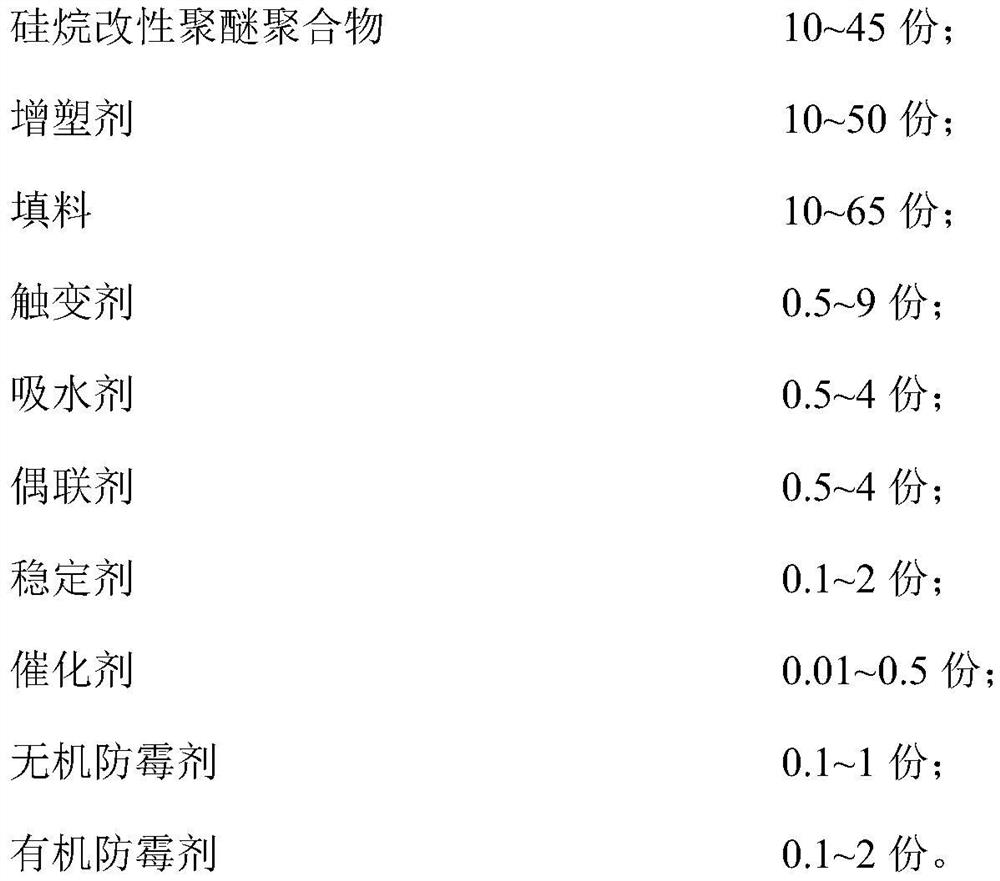

[0038] A kind of compound anti-mold silane modified polyether sealant (hereinafter referred to as anti-mold glue), comprising the raw materials of the following table:

[0039] Raw material composition and mass parts in the embodiment 1 of table 1

[0040]

[0041] The preparation method of anti-mildew glue is as follows:

[0042] (1) Mix the plasticizer, filler and stabilizer according to the formula, heat up to 120°C while stirring, decompress and vacuumize, heat and stir for 3 hours to remove moisture;

[0043] (2) Cool down to 40°C, fill with nitrogen and / or dry air to release the vacuum to normal pressure, and then prepare the dehydrated glue;

[0044] (3) Add silane-modified polyether polymer, thixotropic agent, inorganic anti-mold agent and organic anti-mold agent to the dehydrated mortar, stir for 10 minutes, decompress and vacuumize to remove air and moisture, and stir for 30 minutes to make the raw materials well mixed;

[0045] (4) Vacuum under reduced pressur...

Embodiment 2

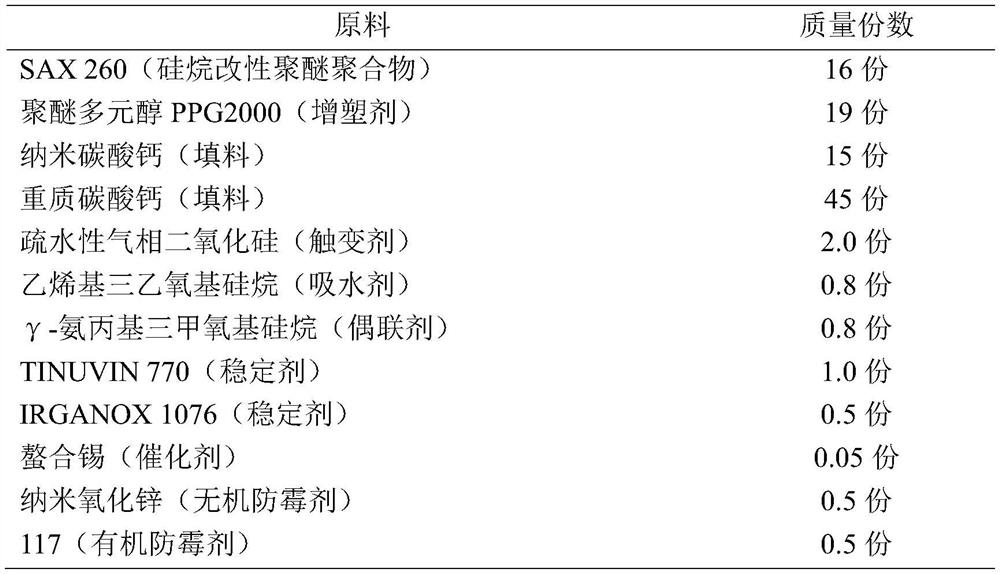

[0048] A kind of mold-proof glue, comprises the raw material of following table:

[0049] Raw material composition and mass parts in the embodiment 2 of table 2

[0050]

[0051] The preparation method of mold-proof glue is the same as embodiment 1.

Embodiment 3

[0053] A kind of mold-proof glue, comprises the raw material of following table:

[0054] Raw material composition and mass parts in the embodiment 3 of table 3

[0055]

[0056]

[0057] The preparation method of mold-proof glue is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com