Preparation method of biodegradable composite material

A technology of biodegradable and composite materials, applied in the field of preparation of biodegradable composite materials, can solve the problems of thermal insulation performance and antibacterial performance without any contribution, impact strength and elongation at break cannot meet the needs and other problems, and achieve antibacterial properties. Excellent effect, easy to scale production, and strong fresh-keeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

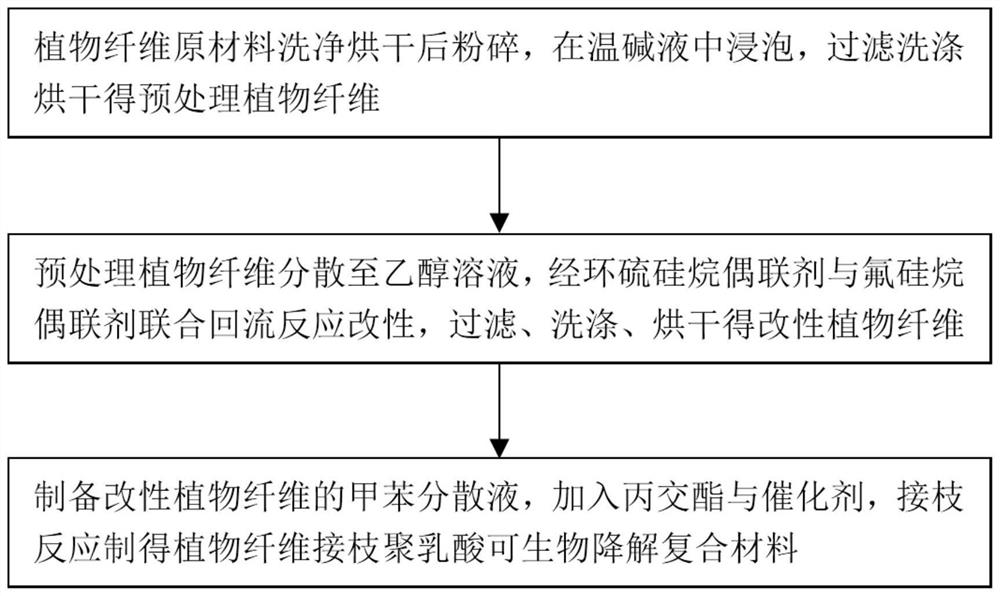

Method used

Image

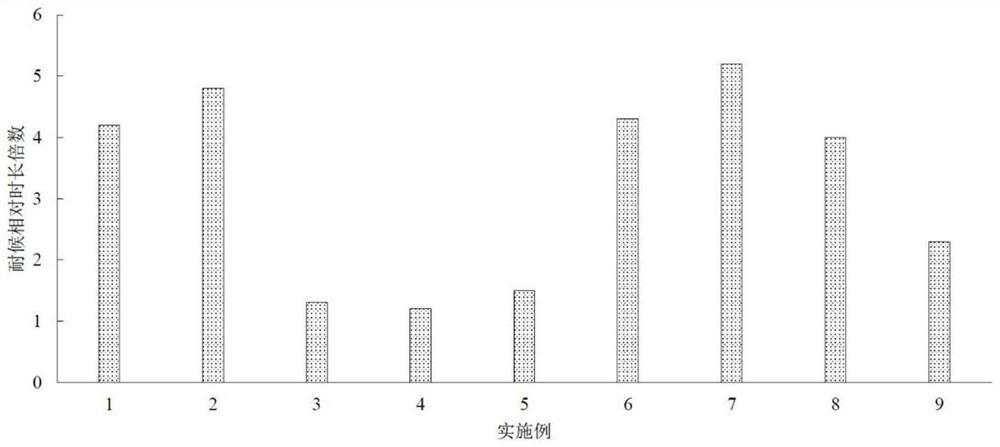

Examples

Embodiment 1

[0067] Embodiment 1: a kind of food packaging material:

[0068] S110: Clean and dry the wheat straw, crush it until it passes through a 200-mesh sieve to obtain plant fiber powder, soak it in 2% sodium hydroxide solution at 35°C for 5 hours, filter it, wash it until the lotion is neutral, and dry it to obtain pretreatment plant fibres;

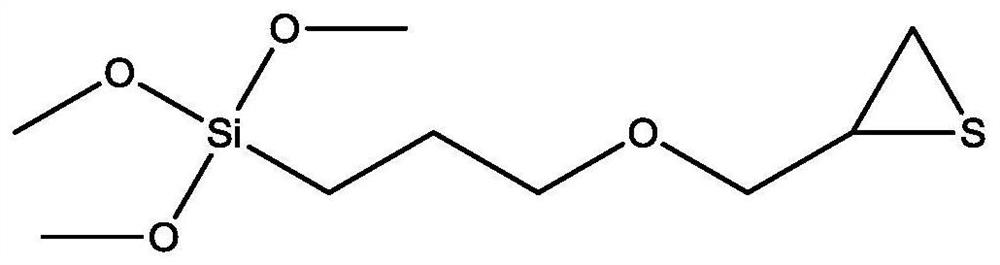

[0069] S120: Add 100g of pretreated plant fibers to 500mL of 80% ethanol solution, heat to 50°C under stirring at 300r / min to disperse evenly, add 1g of epithiosilane coupling agent represented by formula (1) and 0.3g of tridecafluorooctyl base trimethoxysilane, heated to 80°C for reflux reaction for 1 hour, filtered, washed with water until the lotion was neutral, and dried at 55°C to constant weight to obtain modified plant fibers;

[0070] S130: Ultrasonic dispersion of modified plant fiber with acetone, centrifugal washing three times, then adding toluene for ultrasonic dispersion, centrifugal washing three times, to obtain a toluene dis...

Embodiment 2

[0072] Embodiment 2: Another kind of food packaging material:

[0073] S110: Clean and dry corn stalks, crush them until they pass through a 200-mesh sieve to obtain plant fiber powder, soak them in 5% sodium hydroxide solution at 35°C for 5 hours, filter them, wash until the lotion is neutral, and dry them to obtain pretreatment plant fibres;

[0074] S120: Add 100g of pretreated plant fibers to 500mL of 75% ethanol solution, heat to 50°C under stirring at 300r / min to disperse evenly, add 0.6g of epithiosilane coupling agent represented by formula (1) and 0.6g of tridecafluoro Octyltriethoxysilane, heated to 82°C for reflux reaction for 1 hour, filtered, washed with water until the lotion was neutral, dried at 55°C to constant weight to obtain modified plant fibers;

[0075] S130: Ultrasonic dispersion of modified plant fiber with acetone, centrifugal washing three times, then adding toluene for ultrasonic dispersion, centrifugal washing three times, to obtain a toluene disp...

Embodiment 3

[0077] Embodiment 3: Another kind of food packaging material:

[0078] S110: same as S110 of embodiment 1;

[0079] S120: Add 100g of pretreated plant fibers to 500mL of 80% ethanol solution, heat to 50°C under stirring at 300r / min to disperse evenly, add 0.6g of epithiosilane coupling agent shown in formula (1), heat up to 80°C and reflux React for 1 hour, filter, wash with water until the lotion is neutral, and dry at 55°C to constant weight to obtain modified plant fibers;

[0080] S130: same as S130 of embodiment 1;

[0081] S140: Same as S140 in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com