Polyester resin composition, preparation method and application thereof

A technology of polyester resin and composition, which is applied in the field of polyester resin composition and its preparation, and can solve the problems of polluting the environment, impracticability, and low flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

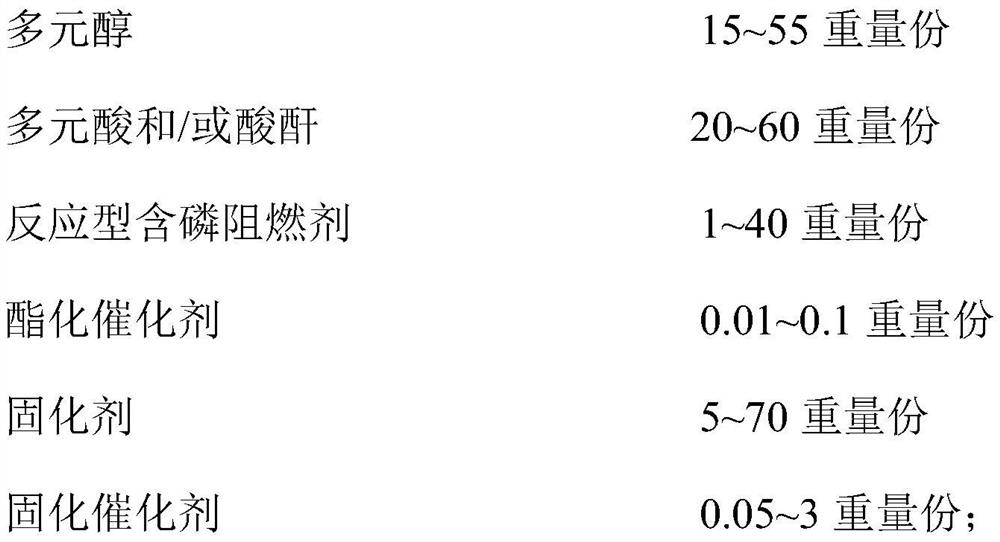

Method used

Image

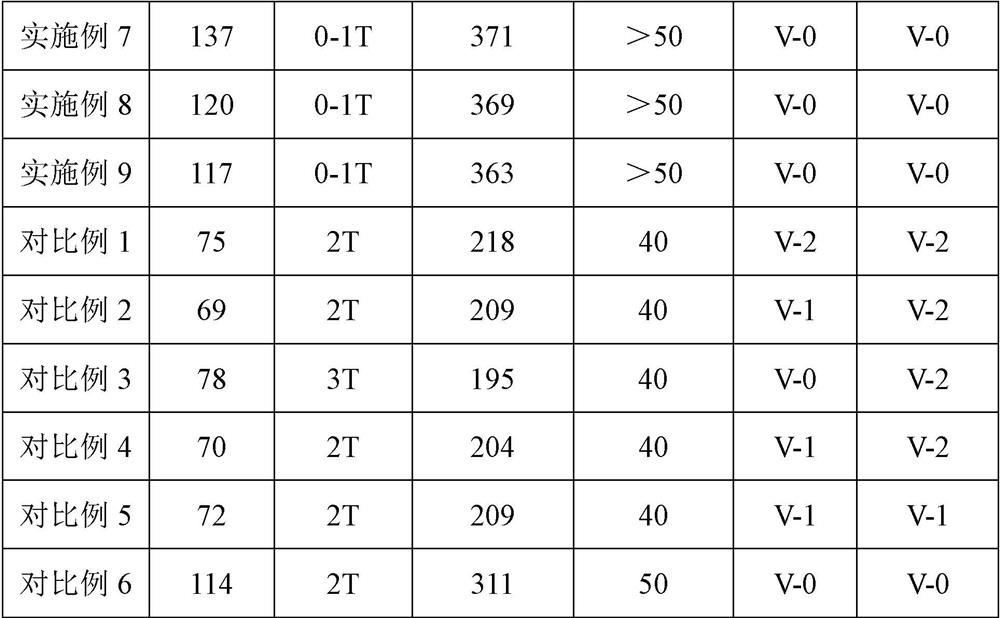

Examples

preparation example 1

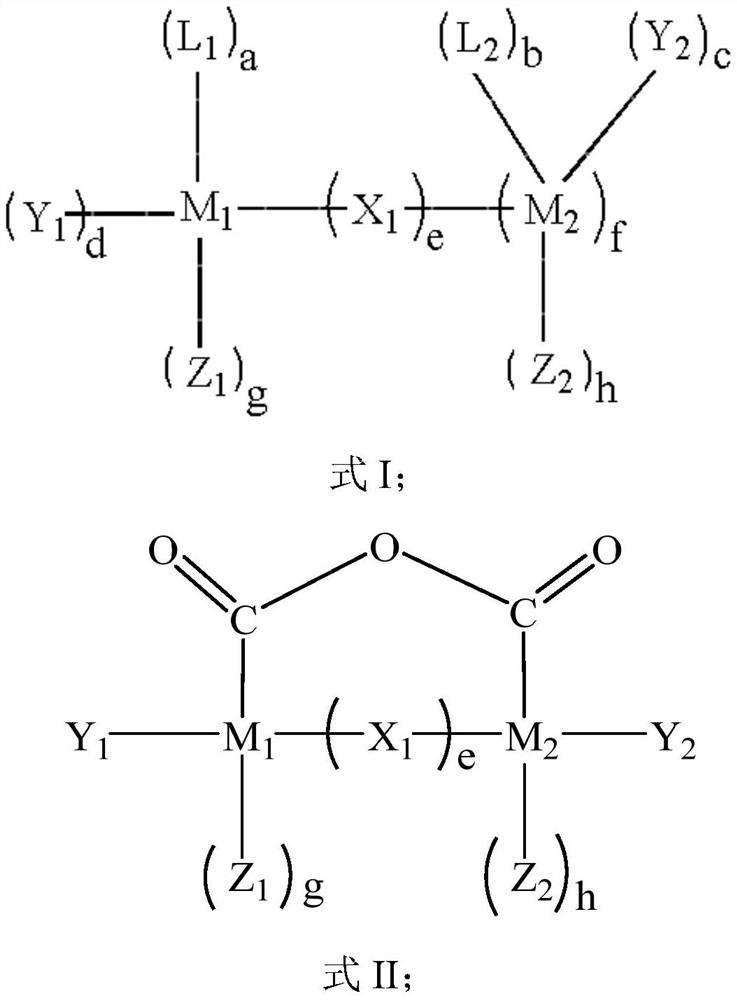

[0112] A reactive phosphorus-containing flame retardant with a carboxyl group, the structure is as follows:

[0113]

[0114] The preparation method is as follows:

[0115] (1) Add 0.5mol dimethyl hydroxymethyl phosphite, 0.5mol 3-[(2-hydroxyethyl)amino]propanol, 100mL ethanol, 0.05mol sodium hydroxide and 0.05g DMAP into the reaction kettle, and heat up Return to ethanol, react under stirring for 24 hours, wash with water until neutral after the reaction, and obtain an aqueous solution of the hydroxyl product;

[0116] (2) Add 30g of potassium permanganate to a 500mL beaker, adjust the pH to 9.8 with NaOH, place the potassium permanganate solution in an ultrasonic cleaner (set temperature at 45°C, ultrasonic power at 100W), and then Add the aqueous solution of the hydroxyl product obtained in step (1) dropwise to the potassium permanganate solution in the environment, and keep the reaction temperature at about 45° C.; when the reaction temperature begins to drop, heat the...

preparation example 2

[0119]A reactive phosphorus-containing flame retardant with a carboxyl group, the structure is as follows:

[0120]

[0121] The preparation method is as follows:

[0122] Add 1 mol of dimethyl phosphite and 0.5 mol of hexadienedioic acid into the reactor, stir and mix well in 300 mL of glacial acetic acid at 60°C under the protection of nitrogen; then add 1 mmol of platinum catalyst in glacial acetic acid solution dropwise into the reactor The reaction was continued at 60°C for 15 h; the product was isolated and purified to obtain the target product with the above structure.

[0123] 1 H NMR (DMSO, 400MHz, TMS): δ11.91-12.42(br,2H,-COOH),3.55-3.76(d,12H,-CH 3 ),3.11-3.59(d,2H,-CH-),1.46-1.78(d,4H,-CH 2 -).

preparation example 3

[0125] A reactive phosphorus-containing flame retardant with a carboxyl group, the structure is as follows:

[0126]

[0127] The preparation method is as follows:

[0128] Add 1 mol of dimethyl phosphite and 1 mol of 5-vinyl isophthalic acid into the reactor, stir and mix well in 300 mL of glacial acetic acid at 65°C under nitrogen protection; then add 1 mmol of glacial acetic acid with platinum catalyst dropwise into the reactor Solution, continue to react at 65°C for 12h; separate and purify the product to obtain the target product with the above structure.

[0129] 1 H NMR (DMSO, 400MHz, TMS): δ12.19-12.87(br,2H,-COOH),7.87-8.05(m,3H,Pr-H),3.31-3.72(d,6H,-CH 3 ),2.71-3.05(m,1H,-CH-),1.31-1.52(d,3H,-CH 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com