High-temperature-resistant large-temperature-difference elastic-tough cement paste system and preparation method thereof

A cement slurry, large temperature difference technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problem of less research on high temperature resistant elastic and tough cement slurry system, the integrity of cement ring seal is easy to seal failure, long sealing It is difficult to guarantee the quality of cementing in the section, so as to prevent the decline of high temperature strength, improve the mechanical properties, and enhance the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

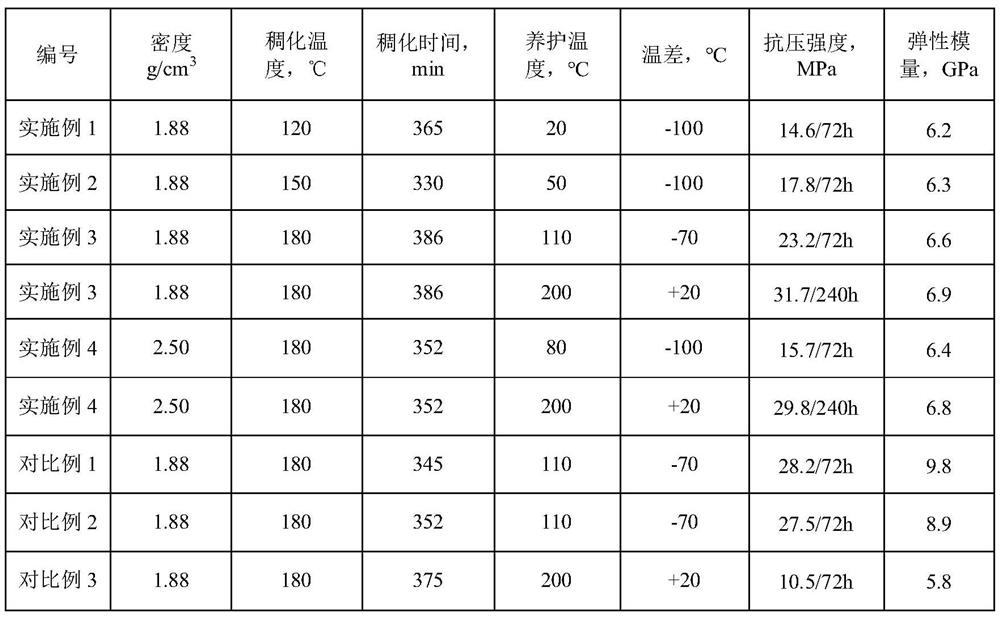

Examples

Embodiment 1

[0041] Weigh 600g of G-grade high sulfate-resistant oil well cement, 210g of strength-stabilizing material, 18g of expansion agent, 36g of elastic material, 0.6g of toughening material, 30g of fluid loss reducer, 15g of retarder, 9g of early strength agent, and defoamer 3g, fresh water 250g.

[0042] Among them: the G-grade high sulfur-resistant oil well cement is Jiahua G-grade high sulfate-resistant oil well cement, Sichuan Jiahua Cement Factory, G-grade high sulfate-resistant oil well cement;

[0043] The strength-stabilizing material is silicon powder (120 mesh);

[0044] The expansion agent is magnesium oxide;

[0045] The elastic material is an elastic particle (solid);

[0046] The toughening material is an organic toughening fiber;

[0047] The retarder AMPS-IA multi-polymer copolymer retarder;

[0048] The fluid loss reducer is an AMPS terpolymer fluid loss reducer;

[0049] The early strengthening agent is sodium metasilicate;

Embodiment 2

[0054] Weigh 600g of G-grade high sulfate-resistant oil well cement, 300g of strength-stabilizing material, 24g of expansion agent, 48g of elastic-resistant material, 6g of toughening material, 15g of fluid loss reducer, 18g of retarder, 6g of early strength agent, and defoamer 6g, fresh water 392g.

[0055] Among them: the G-grade high sulfur-resistant oil well cement is Jiahua G-grade high sulfate-resistant oil well cement;

[0056] The high-temperature strength stable material is compounded from silicon powder (120 mesh) and silicon powder (180 mesh), the mass ratio of the two is 2:3, and the two can be evenly mixed dry;

[0057] The expansion agent is magnesium oxide;

[0058] The elastic material is styrene-butadiene latex;

[0059] The toughening material is an inorganic mineral fiber;

[0060] The fluid loss reducer is an AMPS terpolymer fluid loss reducer;

[0061] Described set retarder is AMPS-IA multiple copolymer retarder;

[0062] The early strengthening agen...

Embodiment 3

[0066] Weigh 600g of G-grade high sulfur-resistant oil well cement, 360g of strength-stabilizing material, 30g of expansion agent, 60g of elastic material, 9g of toughening material, 12g of fluid loss reducer, 23g of large retarder, 9g of early strength agent, and 30g of interface enhancer , defoamer 9g, fresh water 300g.

[0067] Among them: the G-grade high sulfur-resistant oil well cement is Jiahua G-grade high sulfate-resistant oil well cement;

[0068] The high-temperature strength-stabilizing material is compounded of silicon powder (120 mesh), silicon powder (180 mesh), and microsilicon. The mass ratio of the three is 2:3:1, and the three can be evenly mixed dry;

[0069] The expansion agent is magnesium oxide;

[0070] The elastic material is styrene-acrylic latex;

[0071] The toughening material is an inorganic mineral fiber;

[0072] The fluid loss reducer is an AMPS terpolymer fluid loss reducer;

[0073] Described set retarder is AMPS-IA multiple copolymer ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com