Alignment method of SE imbricated cell printing system

A printing system and printing position technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of increased probability of hidden cracks and decreased appearance quality of shingled batteries, simplifying the alignment process, preventing hidden cracks in slices, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

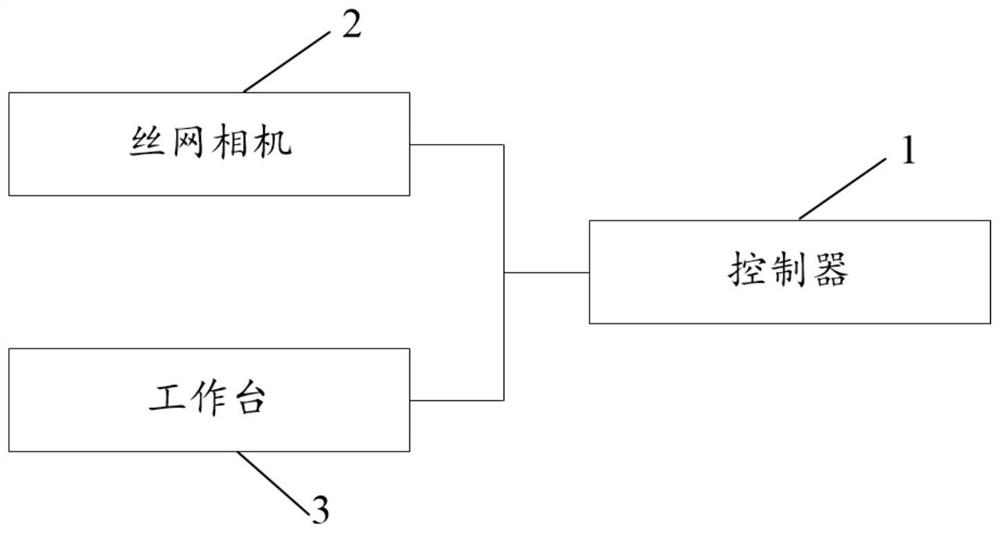

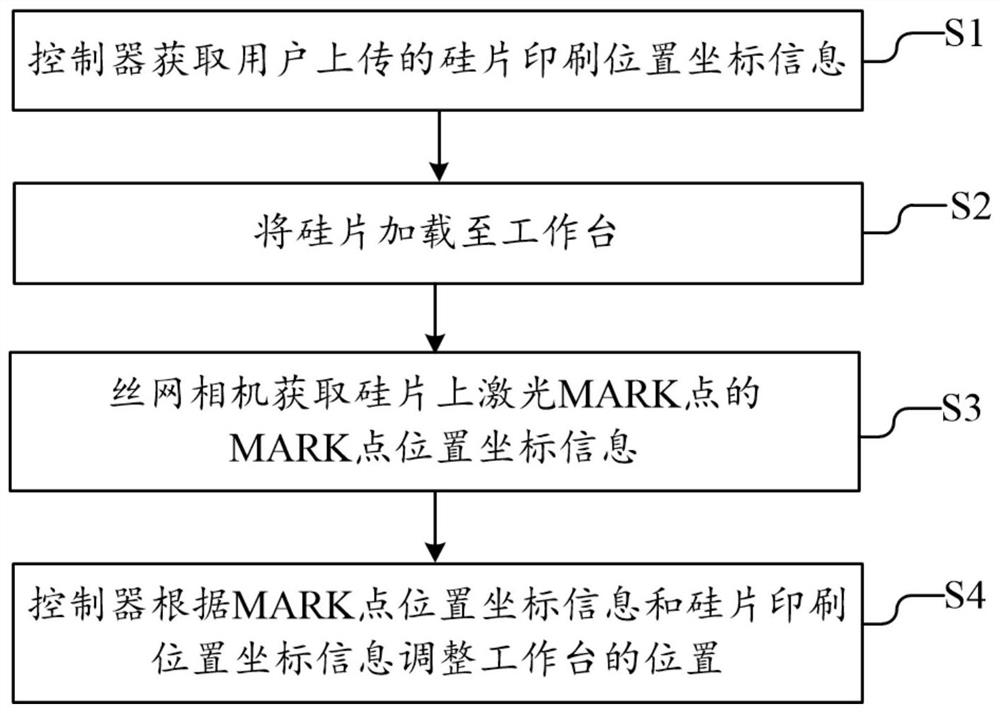

[0044] refer to figure 1 , as the first aspect of the present invention, the SE shingled battery electrode printing system includes a controller 1, a workbench 2 and a screen camera 3, and the screen camera 3 is arranged above the workbench 1; the silicon wafer 4 to be printed is placed on the workbench.

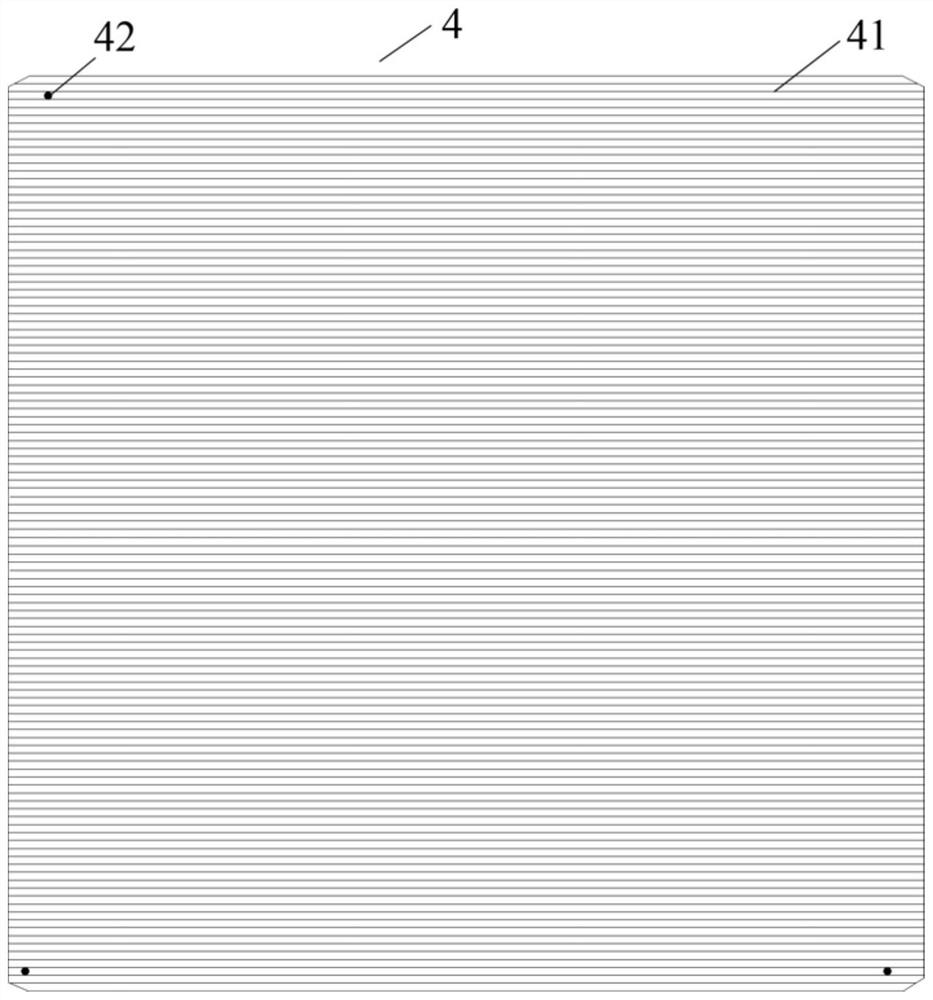

[0045] refer to figure 2 The front side of the silicon wafer 4 is provided with a plurality of sub-gate laser grooves 41 parallel to each other and three MARK points 42, and the three MARK points are distributed in a triangle. This distribution form can effectively determine the deviation between the silicon wafer 4 and the predetermined printing position. It provides a data basis for adjusting the placement angle of the silicon wafer 4 to ensure printing acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com