Colloidal solution mixing device

A technology of mixing device and solution, applied in mixer, dissolving, transportation and packaging, etc., can solve the problems of affecting the uniformity of mixed products, incomplete mixing, poor mixing effect, etc. The effect of force space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

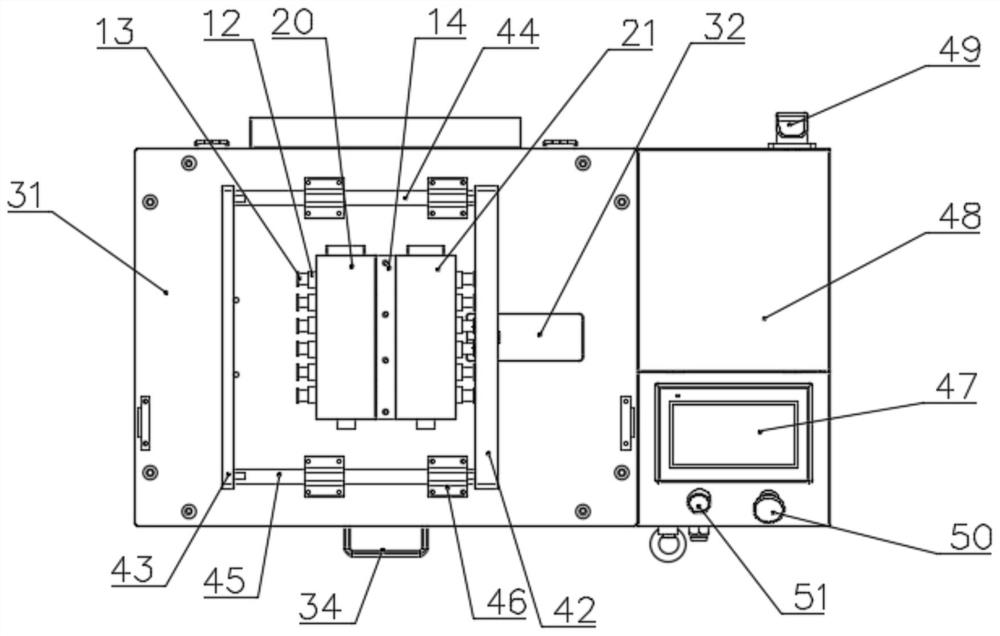

[0075] As an embodiment, the mixing device further includes a frame 3 on which a base 31 is installed, and each mixing chamber 1 is installed on the base 31 . Preferably, each mixing chamber 1 is detachably installed on the base 31 . The mixing chamber 1 is set to be detachably installed on the base 31. When the inside of the mixing chamber 1 is worn, it can be replaced in time; at the same time, the mixing chamber 1 can be disassembled from the base 31 for cleaning, thereby avoiding Clean dead corners; in addition, the mixing chamber 1 can be reused after thorough cleaning, saving costs.

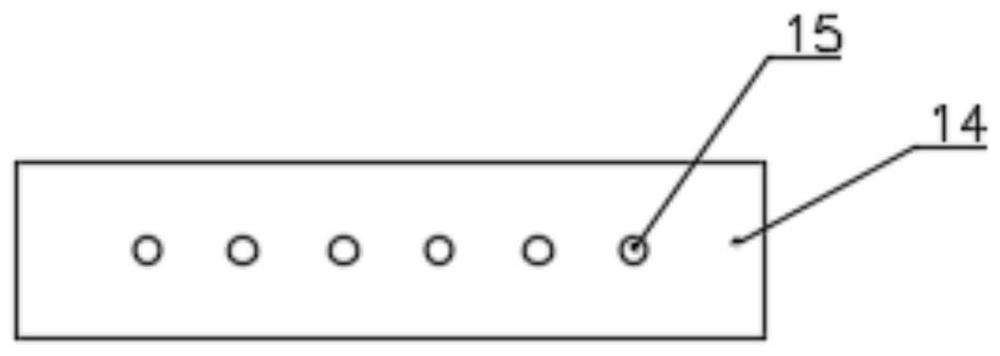

[0076] As an implementation manner, in order to facilitate cleaning and avoid cleaning dead ends, the liquid passing plate 14 is detachably mounted on the base 31 . Specifically, the liquid-passing plate 14 can be detachably installed on the base 31 by any means, such as bolts, quick clamps, etc., as long as the liquid-passing plate 14 can be detachably mounted on the base 31 . In this em...

Embodiment 2

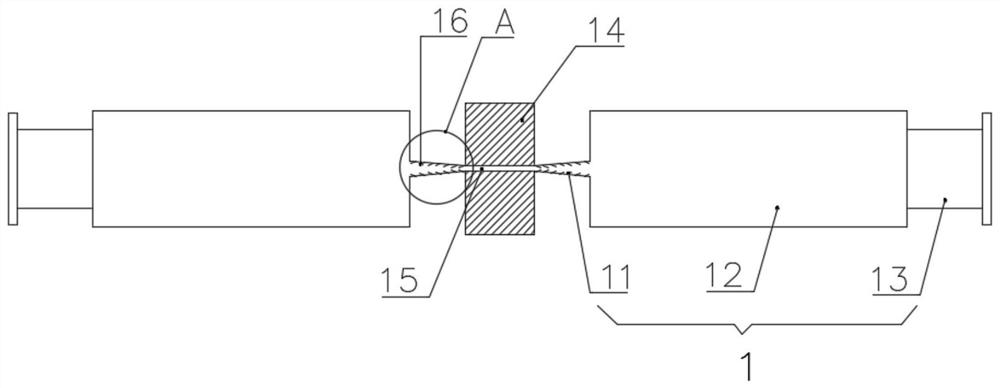

[0094]To produce different types of mixing chambers 1, change the inner diameter of the first cylindrical body 11 of the mixing chamber 1, the ratio of the inner diameter of the second cylindrical body 12 to the first cylindrical body 11, and the ratio of the side wall of the first cylindrical body 11 to the first cylindrical body 11. The joint of the two cylinders 12 is inclined inwardly towards the joint of the other first cylinder 11, the included angle between the scaly ribs 16 and the inner wall of the first cylinder 11 (the scaly ribs 16 face the same direction as the inner wall of the first cylinder 11). The second cylinder 12 connected to the first cylinder 11), the rest of the structures are the same, and the same batch of collagen is mixed for the same time in the different mixing chambers 1 obtained, and the rest of the test conditions are the same to obtain the collagen mixed solution. The pushing resistance of particle diameter and piston rod 13, test result is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com