A kind of nanobubble isotope separation method and separation device and cascade

A technology for isotope separation and nanobubble, which is applied in the fields of nanotechnology, colloid and interface, and isotope separation technology, can solve problems such as the separation method of nanobubble isotopes, etc., and achieves the effect of low cost, simple process and fast production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Carbon Isotope Separation

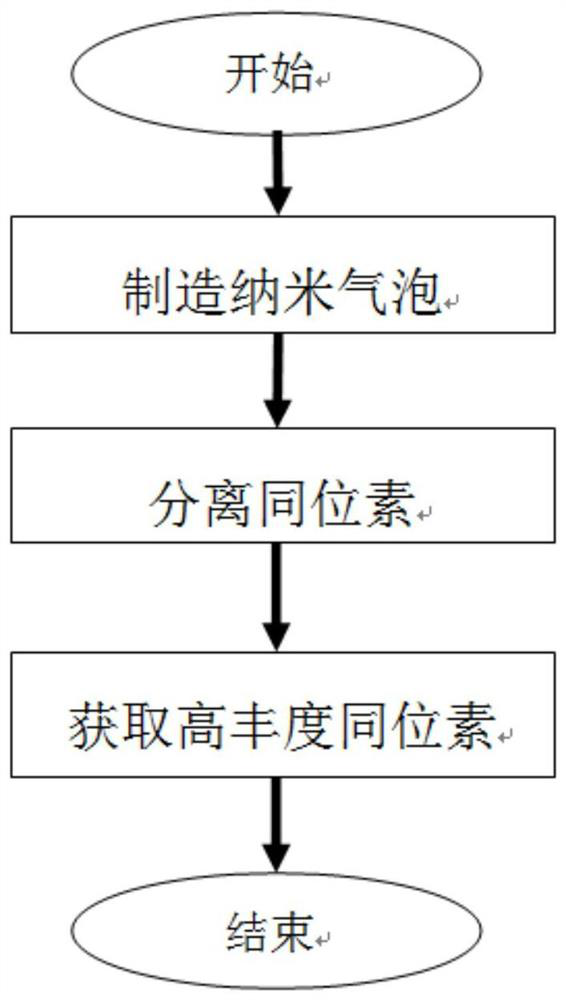

[0041] A nanobubble isotope separation method according to the present invention comprises the following steps:

[0042] Step 1: Make CO 2 nanobubbles

[0043] will CO 2 Mixing gas and water to produce CO containing nanobubble generator 2 Aqueous solutions of nanobubbles;

[0044] like figure 2 shown, the CO produced 2 Nanobubble particle size is in the range of 50-500nm, of which CO2 is less than 200nm 2 Nanobubbles account for more than 70%; CO 2 The density of nanobubbles is 10 8 bubbles / ml;

[0045] Step 2: Separation of carbon isotopes

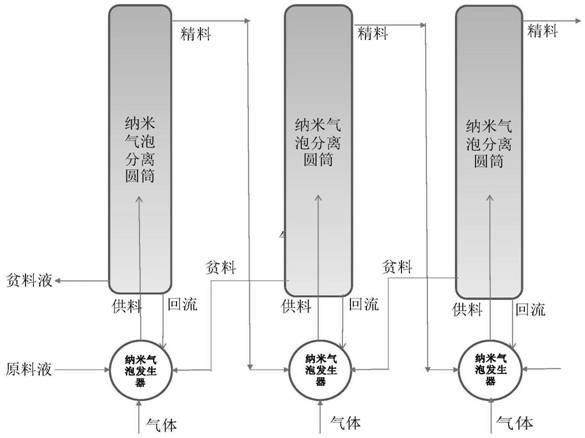

[0046] The CO-containing 2 The aqueous solution of nanobubbles is pumped into a 1-meter-high vertical separation cylinder, where the carbon isotope species to be separated are separated in CO. 2 In nanobubbles; CO 2 The nanobubbles rise with the water in the cylinder, and gradually fill the cylinder, forming a flocculent liquid column of white bubbles;

[0047] CO 2 The nanobub...

Embodiment 2

[0049] Example 2: Carbon Isotope Separation

[0050] A nanobubble isotope separation method according to the present invention comprises the following steps:

[0051] Step 1: Make CO 2 nanobubbles

[0052] will CO 2 The gas and water are mixed, and the CO is rapidly dispersed in the water by the nano-bubble generator 2 bubbles, making 0.1-100 microns of CO 2 Micron bubbles, and then use the pressure dissolved gas method to disperse the CO 2 Micro-bubbles further turn into CO 2 Nano-bubble, the particle size of the nano-bubble is 50-500nm, of which the nano-bubble less than 200nm accounts for more than 75%, and the density of the nano-bubble reaches 3×10 8 air bubbles / ml, and have a long lifespan in water, creating conditions for isotope separation.

[0053] Step 2: Separation of carbon isotopes

[0054] The CO-containing 2 The aqueous solution of nanobubbles is pumped into a 1-meter-high vertical separation cylinder, where the carbon isotope species to be separated ar...

Embodiment 3

[0056] Example 3: Separation of Lithium Isotopes

[0057] A nanobubble isotope separation method according to the present invention comprises the following steps:

[0058] Step 1: Make CO 2 nanobubbles

[0059] will CO 2 Gas and Li 2 SO 4 The solution is mixed, and the CO in the solution is quickly dispersed by the nanobubble generator 2 bubbles, making 50-100 microns of CO 2 Micron bubbles, and then use the pressure dissolved gas method to disperse the CO 2 Micro-bubbles further turn into CO 2 Nano-bubble, the particle size of the nano-bubble is 50-500nm, of which the nano-bubble less than 200nm accounts for more than 70%, and the density of the nano-bubble reaches 10 8 bubbles / ml or more, and in Li 2 SO 4 The longer lifetimes present in solution create conditions for isotope separation.

[0060] Step 2: Separation of Lithium Isotopes

[0061] The CO-containing 2 Li nanobubbles 2 SO 4 The solution is pumped into a vertical separation cylinder 10 meters high, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com