Low-temperature sintered zirconia ceramic substrate

A zirconia ceramic, low-temperature sintering technology, applied in ohmic resistance heating, application, tobacco and other directions, to achieve the effects of stable use performance, reduced use cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

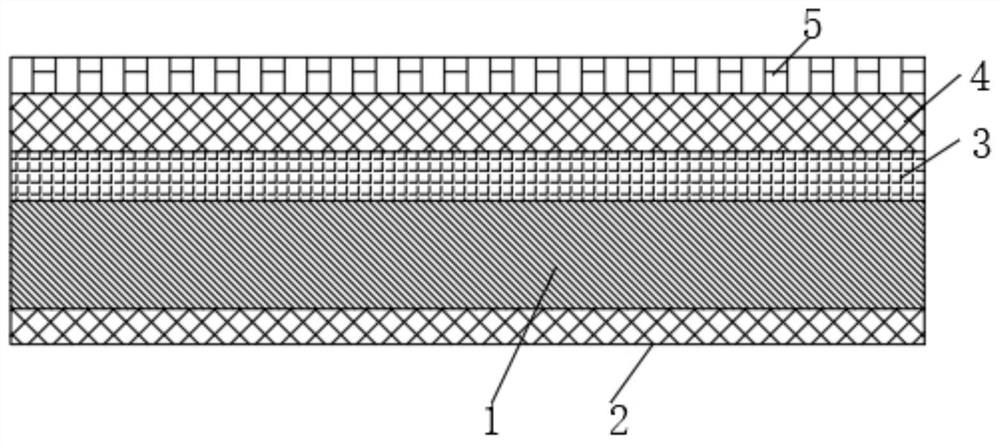

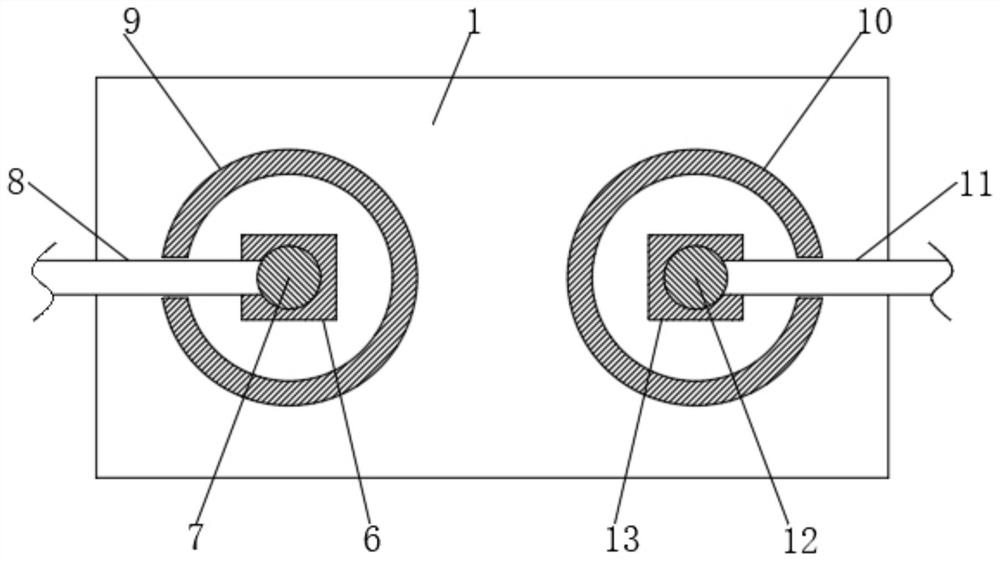

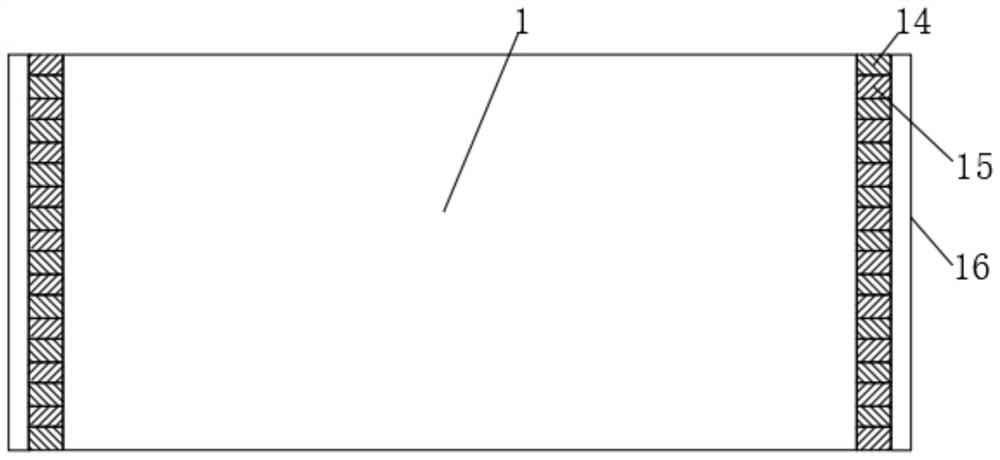

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides a low-temperature sintered zirconia ceramic substrate, including a zirconia ceramic substrate 1, a first insulating layer 2 is fixedly connected to the bottom of the zirconia ceramic substrate 1, and one side of the upper surface of the zirconia ceramic substrate 1 is A first metal protection sheath 9 is fixedly connected, and a first welding pad 6 is arranged inside the first metal protection sheath 9. The bottom of the first welding pad 6 is fixedly connected with a zirconia ceramic substrate 1, and the upper surface of the first welding pad 6 A first circular fixed plate 7 is fixedly connected, one side of the first circular fixed plate 7 is fixedly connected with a first lead wire 8, and the upper surface of the zirconia ceramic substrate 1 is fixedly connected with the first metal protective sheath 9 in a symmetrical position. There is a second metal protection sheath 10, the inside of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com