Lactic acid-producing caproiciproducens derived from pit mud for white spirit brewing and application of lactic acid-producing caproiciproducens

A technology of caproic acid bacteria and inoculum, which is applied in the field of winemaking and achieves the effects of good acid-base tolerance, easy cultivation and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

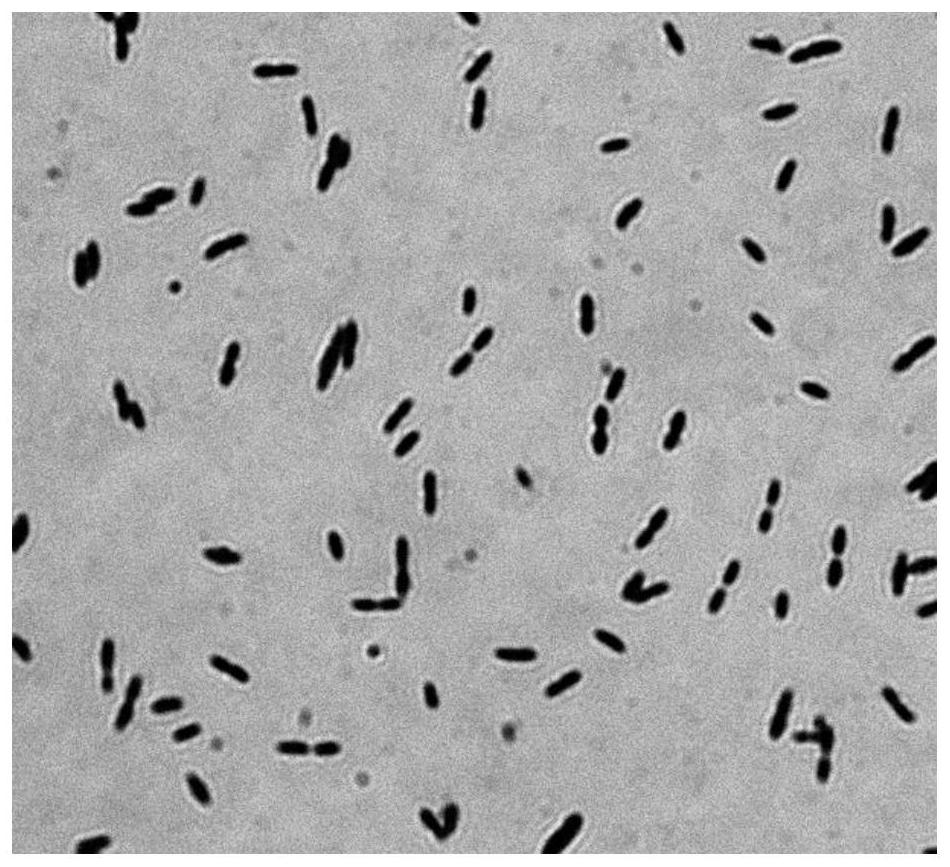

[0044] Example 1: Isolation and Identification of Lactobacillus Caproiciproducens sp.JNLZ26

[0045] (1) Isolation and purification of caproic acid bacteria strains

[0046] Take 1g sample from pit mud and add it to Clostridium glucose liquid culture medium. After culturing for 20 days, inoculate 10% (v / v) inoculation amount into Clostridium glucose liquid medium again, and the growth of bacteria is obvious. Afterwards, the bacterial suspension was diluted and spread on the Clostridium glucose solid medium, cultivated at 37°C for 5-7 days, picked a typical single colony, inoculated into the Clostridium glucose liquid medium for cultivation, and measured the ethanol in the system after 2-3 days. Acid content, screening single bacteria with higher concentration of caproic acid. Repeat the liquid culture and dilution coating operations to isolate and purify the strains and obtain a single colony for identification.

[0047] (2) Strain identification

Embodiment 2

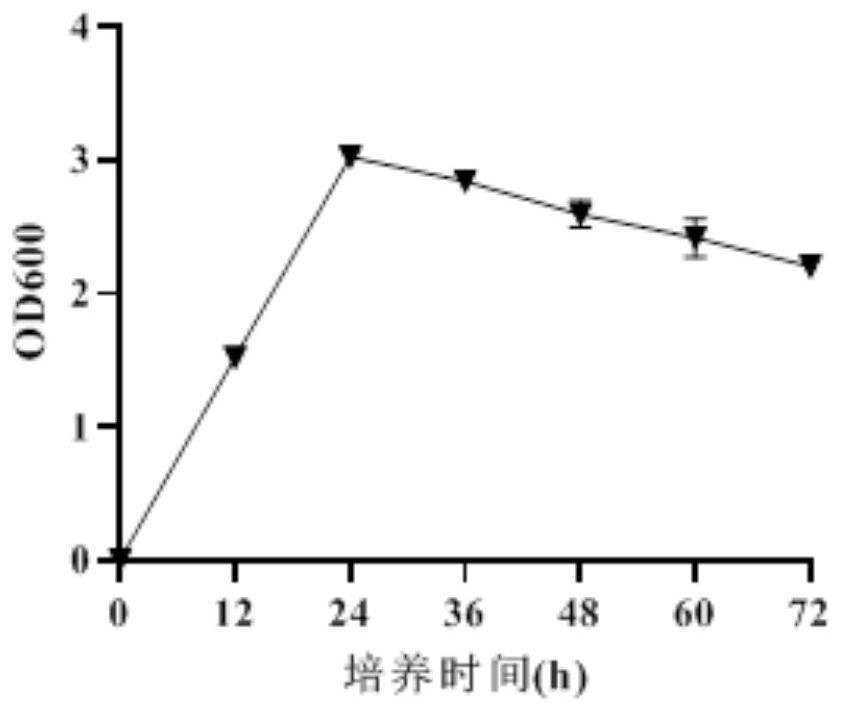

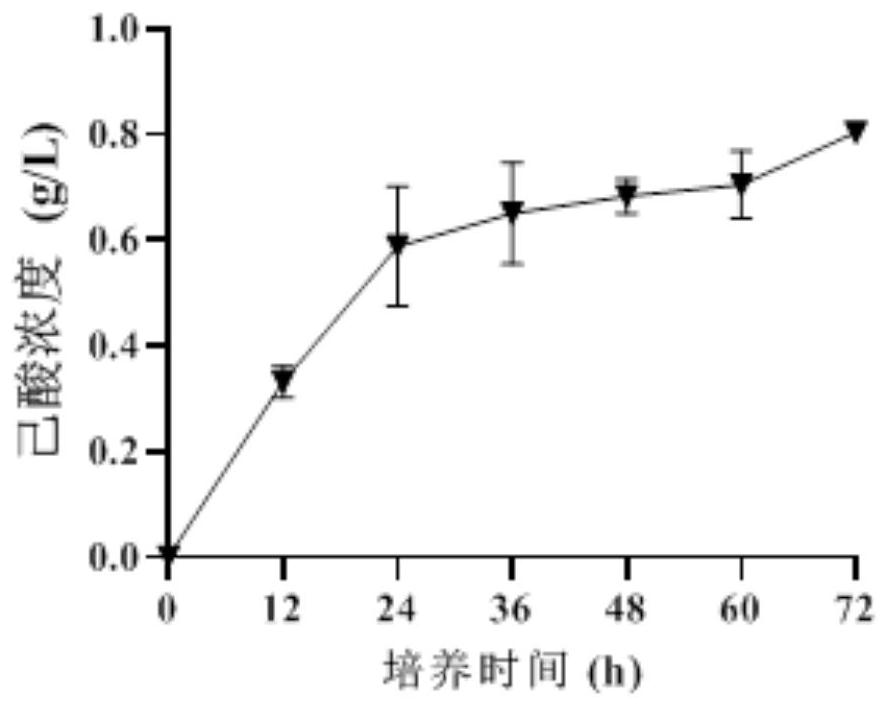

[0056] Embodiment 2: the fermentation culture of caproic acid bacterium Caproiciproducens sp.JNLZ26 and strain property

[0057] (1) the caproic acid bacterium Caproiciproducens sp.JNLZ26 that embodiment 1 is isolated is cultivated through the clostridium glucose liquid culture medium, as Figure 2-Figure 5 , grow 24h, OD 600 up to the maximum, the OD at this time 600 After 72 hours of fermentation, the consumption of glucose was 8.11g / L, the output of hexanoic acid was 0.81g / L, and the output of lactic acid was 11.3g / L.

[0058] (2) The nature of the strain

[0059] Salt-tolerant detection: the caproic acid bacteria Caproiciproducens sp.JNLZ26 that embodiment 1 isolates is based on the clostridium glucose medium, and the concentration gradient of NaCl in the setting medium is 0-8% (w / v), and the concentration interval is 1% (w / v).

[0060] The steps are as follows: respectively detect the bacterial growth of caproic acid bacteria Caproiciproducens sp. JNLZ26 in the medium...

Embodiment 3

[0065] Example 3: caproic acid bacteria Caproiciproducens sp.JNLZ26 applied to starch fermentation to produce lactic acid and caproic acid

[0066] Specific steps are as follows:

[0067] (1) Inoculate the caproic acid bacteria Caproiciproducens sp.JNLZ26 obtained in Example 1 into the Clostridium glucose liquid medium, and culture it for 24 hours at 37° C. to obtain the seed liquid;

[0068] (2) Take the seed solution obtained in step (1), inoculate it into soluble starch medium and ordinary starch medium respectively according to the inoculation ratio of 10% (v / v), and ferment for 60 hours at 37°C, and the volume of the fermentation culture system is 80mL .

[0069] The result is as Figure 8-Figure 9 As shown, caproic acid bacteria Caproiciproducens sp. JNLZ26 is in a vigorous growth period at 0-36h, and the bacterial body settles after 48-60h of fermentation.

[0070] After testing, caproic acid bacteria Caproiciproducens sp.JNLZ26 can ferment soluble starch to produce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com