Hot isostatic pressing sintering preparation method of tungsten oxide-based ceramic target material

A hot isostatic pressing sintering and ceramic target technology, which is applied in metal material coating process, vacuum evaporation coating, sputtering coating, etc., can solve the problems that tungsten oxide-based ceramic target materials cannot be prepared, and achieve Effect of promoting lattice collapse, improving sintering activity, and improving n-type conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] 1. Preparation of doped submicron tungsten oxide-based powder:

[0085] 1) Prepare raw materials: prepare ammonium metatungstate with a purity ≥ 99.99%, and the doping source element components in this embodiment are calculated as Mo:Li:Zr=5:10:1 according to the molar ratio; prepare MoO with the corresponding element ratio 2 , Li 2 O, ZrO 2 Doping source powder, purity ≥ 99.99%; the mass ratio of ammonium metatungstate added to doping source powder is 87:13.

[0086] It is also feasible to purchase other elemental metals, alloy inorganic salts, and organic salts of corresponding elements for the doping source powder, and the effect is similar.

[0087] 2) preparing a premix solution, fully dissolving pure water, organic monomer acrylamide, and crosslinking agent N'N'-methylenebisacrylamide in a weight ratio of 100:10:1 to form a premix solution;

[0088] 3) Preparation of slurry: Add the pure ammonium metatungstate prepared in step 1) and the doping source powder to...

Embodiment 2

[0104] The difference between this example and Example 1 is that the mass fraction of tungsten in the powder is 85% based on tungsten oxide, and the mass fraction of the doping source is 15%. : Zr=10:5:1;

[0105] The remaining steps are the same as in Example 1. The relative density of the obtained tungsten oxide-based ceramics measured by the drainage method is 98.5%, the average grain size is 4.5 μm, the doping elements enter the ceramic lattice, and there is no obvious second phase. The electrical conductivity of the ceramic body is 15S / cm.

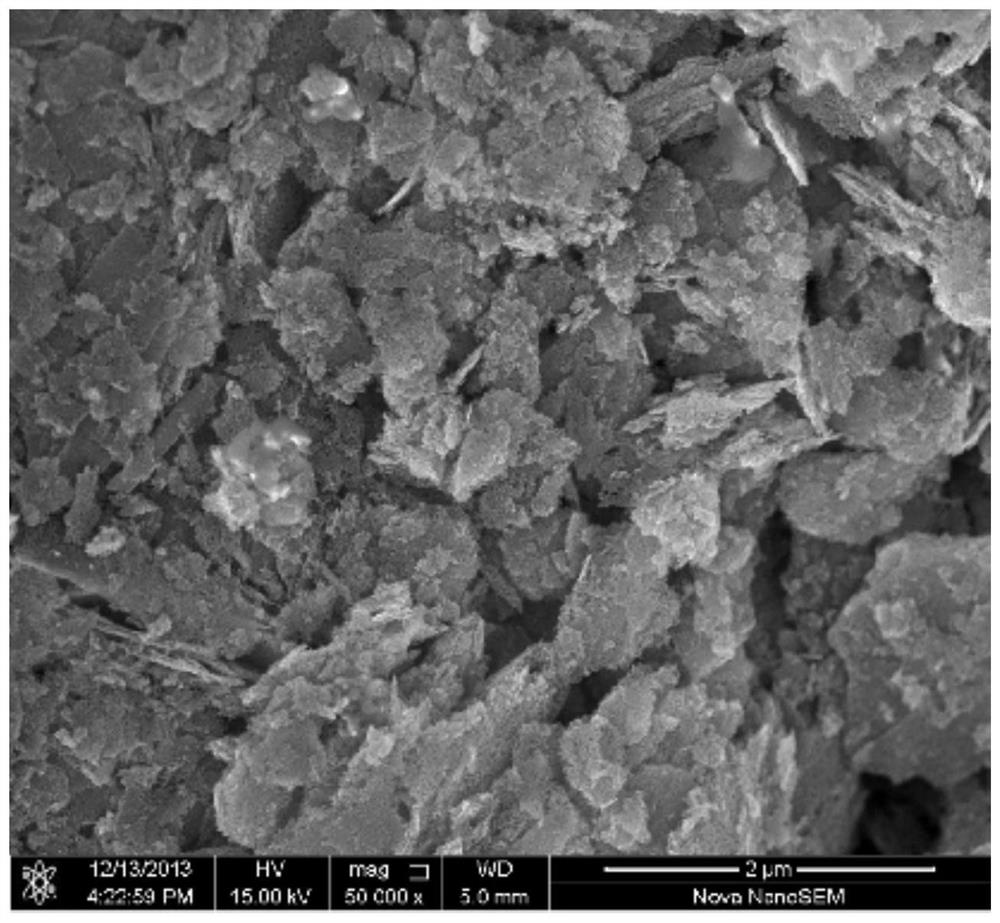

[0106] The electron micrographs of the ceramics prepared in this embodiment are as follows: Figure 5 shown.

Embodiment 3

[0108] 1. Preparation of doped submicron tungsten oxide-based powder:

[0109] 1) Prepare raw materials: prepare ammonium metatungstate with a purity ≥99.99%, and the doping source element components of this embodiment are calculated as Ti:Mo:Zr=10:1:1 according to the molar ratio; prepare the oxidation of the corresponding element ratio Titanium, molybdenum oxide, zirconia doping source powder, purity ≥ 99.999%; the mass ratio of added ammonium metatungstate to doping source powder is 92.2:7.8.

[0110] It is also feasible to purchase other elemental metals, alloy inorganic salts, and organic salts of corresponding elements for the doping source powder, and the effect is similar.

[0111] 2) To prepare a premix solution, the pure water and the organic monomer are a combination of polyvinyl alcohol and polyacrylic acid, wherein the ratio of polyvinyl alcohol to polyacrylic acid is 1:1, and the crosslinking agent is polyethylene glycol, polyethylene glycol A combination of alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com