Flexible reinforced fiber concrete and preparation method thereof

A fiber-reinforced concrete and reinforced technology, which is applied in the field of concrete, can solve problems such as insufficient deformation capacity and high rigidity of concrete, and achieve the effects of improving compatibility, good deformation capacity, and realizing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

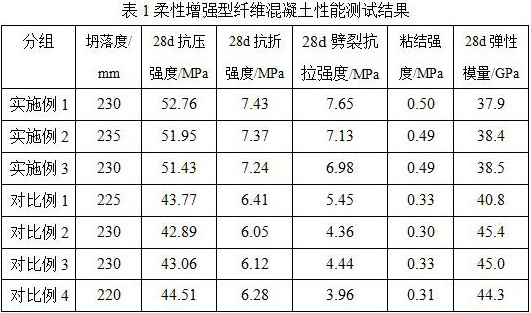

Examples

Embodiment 1

[0033] A flexible reinforced fiber concrete is prepared from the following raw materials in parts by weight: 120 parts of ordinary portland cement, 13 parts of high-iron aluminophosphate cement, 28 parts of modified waste rubber particles, and 7 parts of polyolefin elastomer , 5 parts of flotation deinking slag fiber, 4 parts of modified sepiolite fiber, 15 parts of silicon carbide powder, 7 parts of bamboo fiber powder, 13 parts of polycarboxylate superplasticizer, 4 parts of magnesium fluorosilicate, 12 parts of slag powder parts, 5 parts of fly ash, 165 parts of sand, 470 parts of gravel, and 55 parts of water.

[0034] Described, modified waste rubber particle is made by following steps:

[0035] 1) Make waste tires into waste rubber particles with a particle size of 30-50 mesh;

[0036] 2) Put waste rubber particles in tetraethyl orthosilicate, place at room temperature for 10 hours, filter to obtain semi-swelled rubber particles;

[0037] 3) At 45°C, mix the semi-swell...

Embodiment 2

[0051] A flexible reinforced fiber concrete is prepared from the following raw materials in parts by weight: 110 parts of ordinary portland cement, 15 parts of high-iron aluminophosphate cement, 25 parts of modified waste rubber particles, and 10 parts of polyolefin elastomer , 3 parts of flotation deinking slag fiber, 5 parts of modified sepiolite fiber, 10 parts of silicon carbide powder, 5 parts of bamboo fiber powder, 15 parts of polycarboxylate superplasticizer, 5 parts of magnesium fluorosilicate, 10 parts of slag powder parts, 7 parts of fly ash, 170 parts of sand, 460 parts of gravel, and 60 parts of water.

[0052] Described, modified waste rubber particle is made by following steps:

[0053] 1) Make waste tires into waste rubber particles with a particle size of 30-50 mesh;

[0054] 2) Place waste rubber particles in tetraethyl orthosilicate, place at room temperature for 8 hours, and filter to obtain semi-swelled rubber particles;

[0055] 3) At 50°C, mix the semi...

Embodiment 3

[0065] A flexible reinforced fiber concrete is prepared from the following raw materials in parts by weight: 130 parts of ordinary portland cement, 10 parts of high-iron aluminophosphate cement, 30 parts of modified waste rubber particles, and 5 parts of polyolefin elastomer , 6 parts of flotation deinking slag fiber, 3 parts of modified sepiolite fiber, 20 parts of silicon carbide powder, 10 parts of bamboo fiber powder, 10 parts of polycarboxylate superplasticizer, 3 parts of magnesium fluorosilicate, 15 parts of slag powder 3 parts of fly ash, 160 parts of sand, 480 parts of gravel, and 50 parts of water.

[0066] Described, modified waste rubber particle is made by following steps:

[0067] 1) Make waste tires into waste rubber particles with a particle size of 30-50 mesh;

[0068] 2) Put waste rubber particles in tetraethyl orthosilicate, place at room temperature for 12 hours, filter to obtain semi-swelled rubber particles;

[0069] 3) At 40°C, mix the semi-swellable c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com