Hierarchical pore biochar as well as preparation method and application thereof

A technology of biochar and multi-level pores, applied in separation methods, chemical instruments and methods, carbon compounds, etc., can solve the problems of difficult control of pore structure, cumbersome operation steps, and complicated activation process, so as to improve the removal capacity and source Extensive, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of hydrogen peroxide activated hierarchical porous biochar of the present invention comprises the following steps:

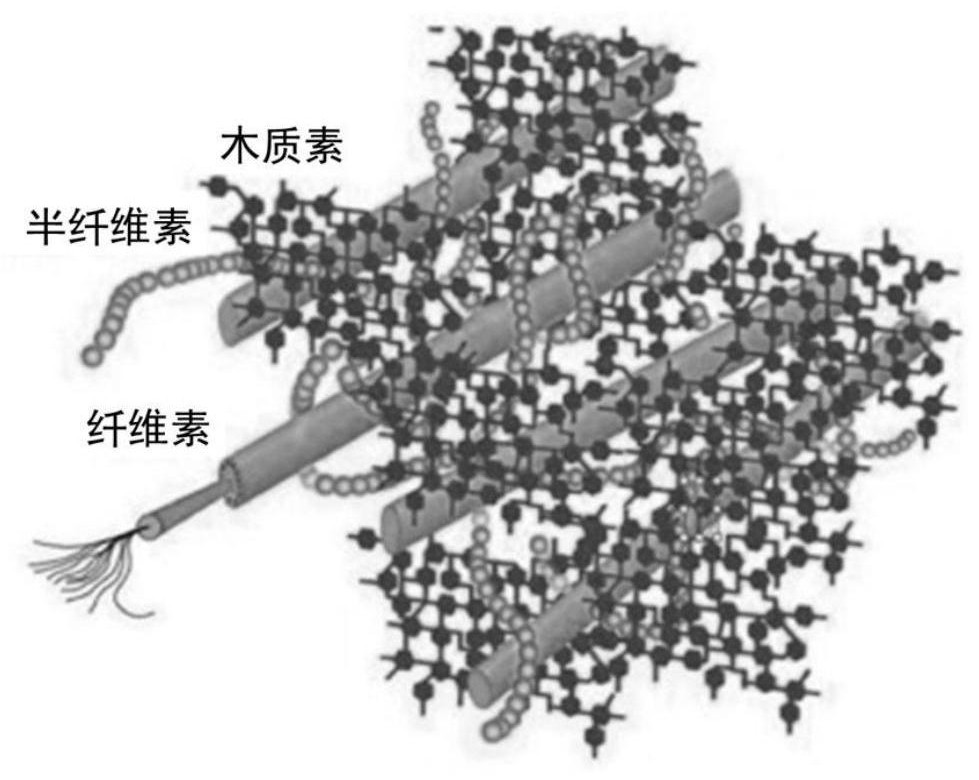

[0033] A. Crush the biomass to a certain particle size, add the biomass to the reactor, and slowly add hydrogen peroxide solution and stir evenly to form a solid-liquid mixture containing biomass and hydrogen peroxide. After hydrothermal reaction, wash and dry to obtain hydrothermal charcoal ;

[0034] B. Put the hydrothermal charcoal in a tube furnace, heat up to a certain temperature in an inert gas atmosphere, and keep it at the target temperature for a certain period of time for pyrolysis, and cool to room temperature after the reaction, and multi-level porous organisms carbon.

[0035] Further, in order to prepare nitrogen-rich biochar, a nitrogen-doping agent is added to the reactor together with the biomass. That is, the present invention also provides a method for preparing hydrogen peroxide-activated nitrogen-doped hierar...

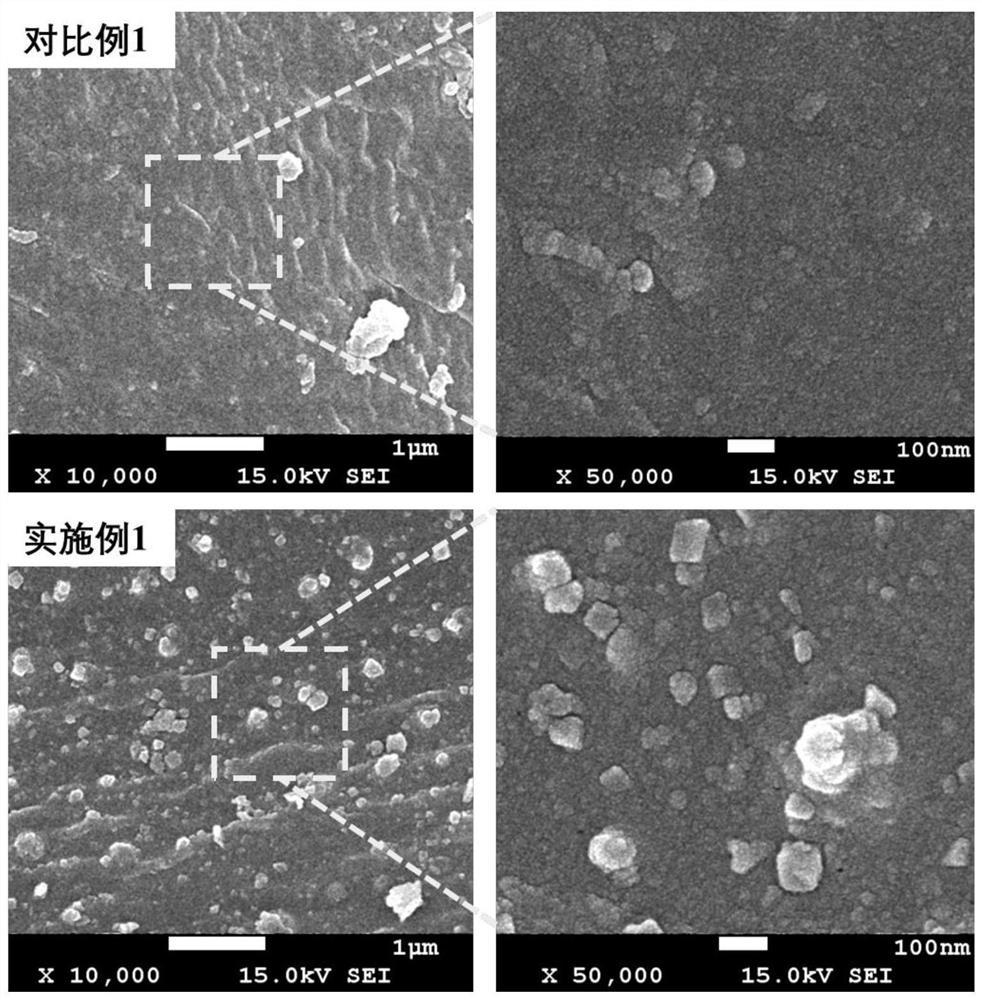

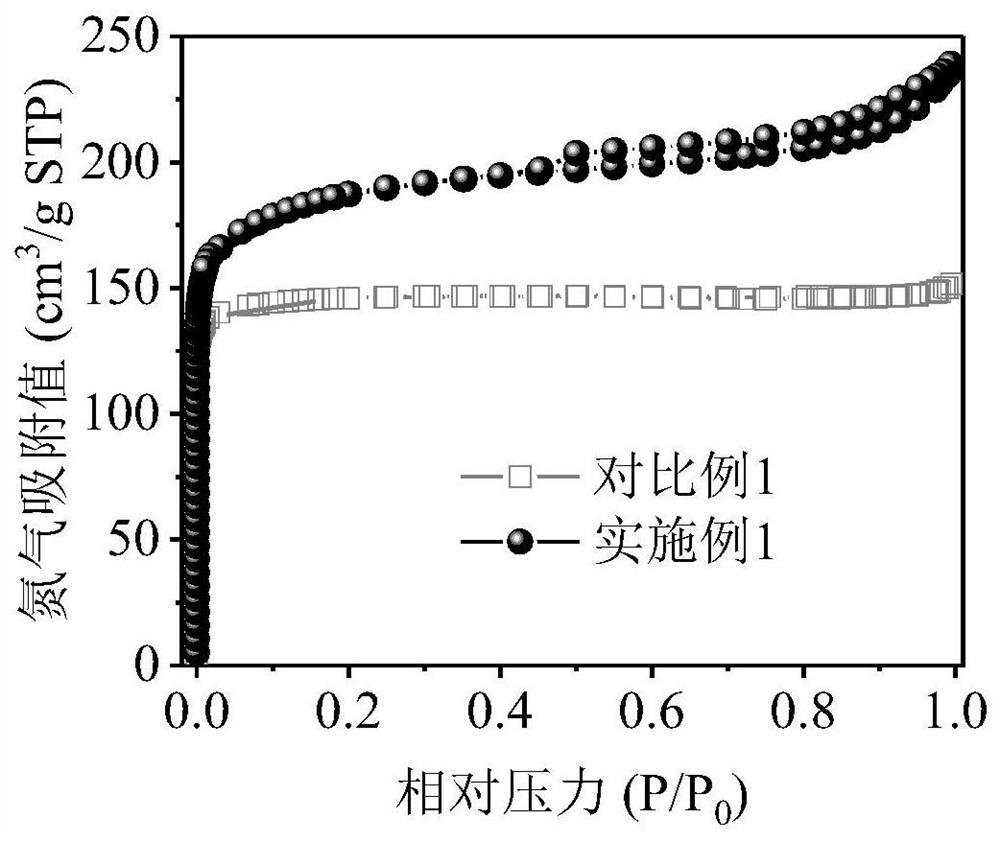

Embodiment 1

[0041] Weigh 5g of cypress sawdust powder with a particle size of 0.15-0.25mm as the biomass raw material, weigh 5g of urea according to the mass ratio of biomass to nitrogen doping agent 1:1, and add the mass concentration of 5% according to the liquid-to-material ratio of 12mL:1g hydrogen peroxide solution to form a solid-liquid mixture. The mixture was transferred to a polytetrafluoroethylene liner, placed in a stainless steel hydrothermal reaction kettle, and hydrothermally reacted at 190° C. for 12 hours. After hydrothermal reaction, cool to room temperature. The reactant was taken out, filtered, washed and dried to obtain hydrothermal nitrogen-containing carbon. The hydrothermal nitrogen-containing carbon is placed in a tube furnace, and N 2 30min to exhaust the air in the furnace. N 2 The flow rate is 150mL / min, the heating rate is 5°C / min, the pyrolysis target temperature is 900°C, and the pyrolysis time is 60min. Cool naturally to obtain nitrogen-doped hierarchi...

Embodiment 2

[0043] Weigh 2.5g of cypress sawdust powder with a particle size of 0.25-0.50mm as the biomass raw material, weigh 5g of melamine according to the mass ratio of biomass to nitrogen doping agent 0.5:1, and add the mass concentration of 10mL according to the liquid-to-solid ratio of 12mL:1g. % hydrogen peroxide solution to form a solid-liquid mixture. The mixture was transferred to a polytetrafluoroethylene liner, placed in a stainless steel hydrothermal reaction kettle, and hydrothermally reacted at 170°C for 24h. After hydrothermal reaction, cool to room temperature. The reactant was taken out, filtered, washed and dried to obtain hydrothermal nitrogen-containing carbon. The hydrothermal nitrogen-containing carbon is placed in a tube furnace, and N 2 30min to exhaust the air in the furnace. N 2 The flow rate is 150mL / min, the heating rate is 5°C / min, the target activation temperature is 800°C, and the activation time is 60min. Cool naturally to obtain nitrogen-doped hier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com