Polishing machine used for castings for elevator brake system and using method thereof

A technology for elevator brakes and grinding machines, which is applied to the cleaning method using gas flow, the cleaning method using tools, and the grinding frame, etc., which can solve the problems of inconvenient movement, troublesome replacement, and affecting the movement of grinding wheels The effect of saving time and effort during the moving process, simple and convenient movement, and simple and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

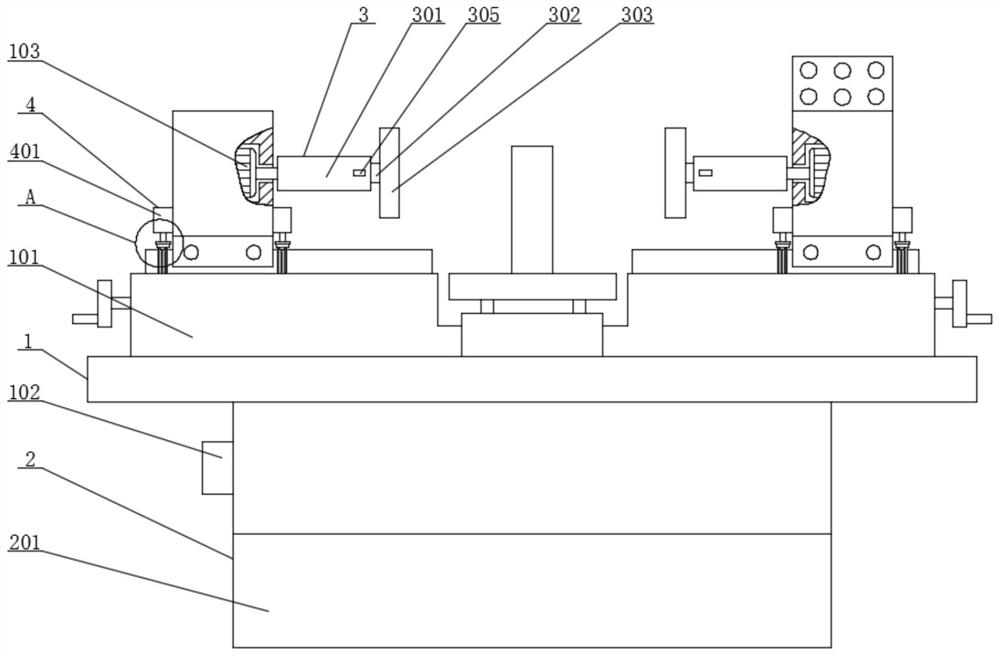

[0033] see Figure 1-6 , the present invention provides a technical solution:

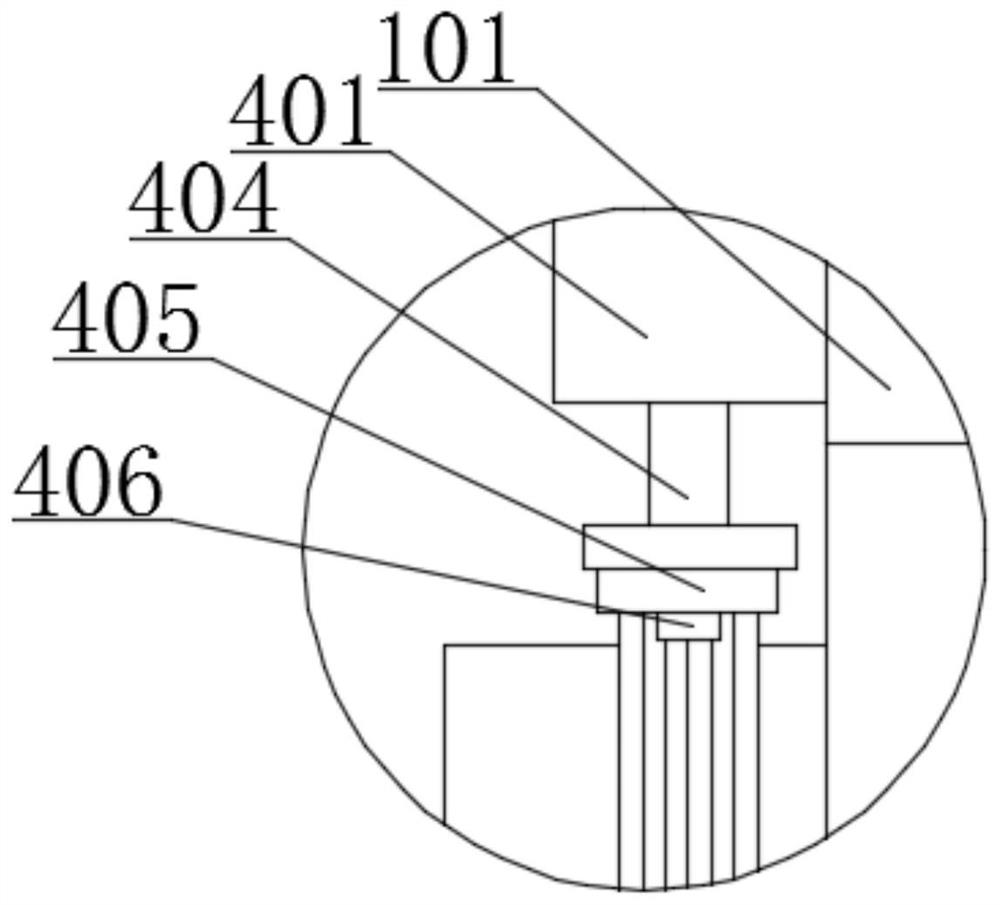

[0034]A grinding machine for castings of an elevator braking system, comprising a main unit 1, a moving unit 2, a replacement unit 3 and a cleaning unit 4, the main unit 1 includes a body 101, a controller 102 and a first motor 103, the controller 102 It is fixedly connected with the body 101, the first motor 103 is fixedly connected with the body 101, the mobile device 2 includes a base 201, the base 201 is fixedly connected with the body 101, and the inner top of the left end surface of the base 201 is sleeved with a second motor 202, the second motor 202 The end of the main shaft is fixedly connected with a first threaded shaft 203, the right end of the first threaded shaft 203 is fixedly connected with a connecting shaft 204, the right end of the connecting shaft 204 is fixedly connected with a second threaded shaft 205, and the second threaded shaft 205 is rotationally connected with the base ...

Embodiment 2

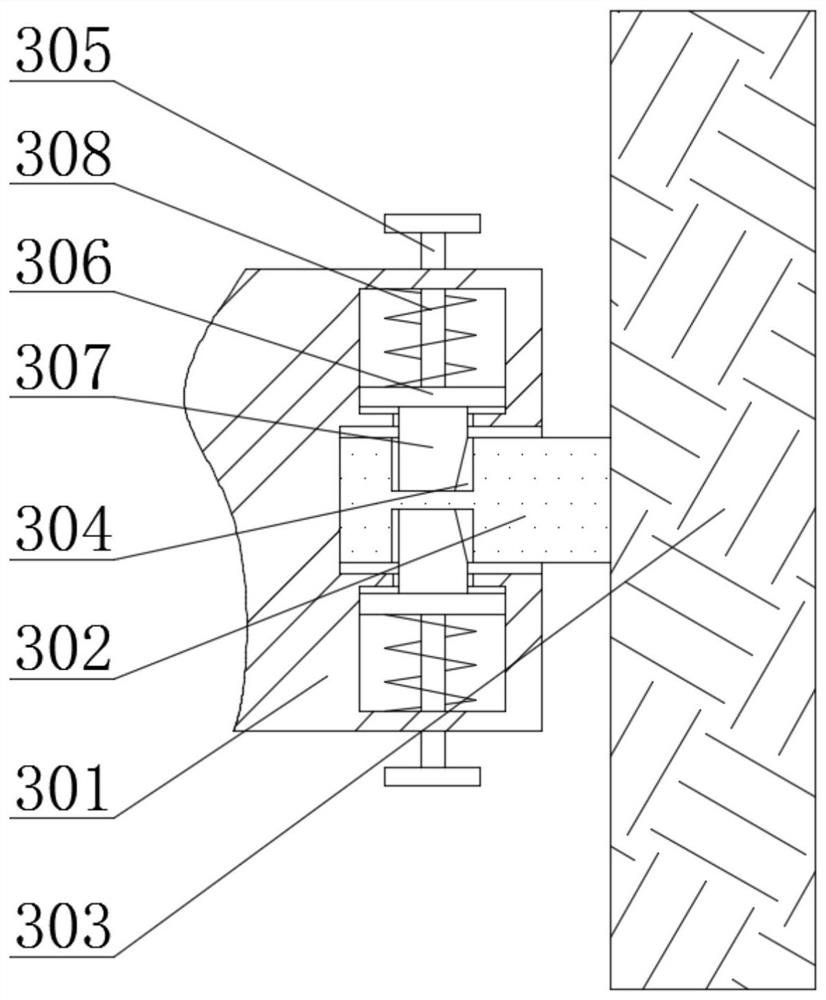

[0038] In embodiment 2, the same part as in embodiment 1 will not be repeated, please refer to the different parts image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 with Figure 9 , the present invention provides a technical solution:

[0039] The cleaning device 4 includes a bellows 407, a support rod 409 and a filter screen 411, the bellows 407 is fixedly connected with the body 101, the bottom surface of the bellows 407 is connected with an air outlet pipe 408, the support rod 409 is fixedly connected with the bellows 407, and the bottom surface of the support rod 409 is fixedly connected There is a fan 410, a filter 411 runs through the bellows 407, and the filter 411 is slidably connected with the bellows 407. This setting is convenient for cleaning debris attached to the slide rail; Fixedly connected, the other end of the third spring 412 is fixedly connected with a block 413, the block 413 runs through the bellows 407, the block 413 is slidably connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com