Underneath alternating type knife rest numerical control lathe

A kind of CNC lathe, alternating technology, applied in the direction of turning equipment, positioning device, tool holder accessories, etc., can solve the problems of inconvenient observation of tools and tool processing conditions, reducing the cutting efficiency of CNC machine tools, and large space occupied by CNC machine tools. The effect of convenient tool setting and observation of processing progress, lowering the center of gravity of the machine tool, and shortening the length of the tool holder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] It is one of the specific implementation modes of the present invention: refer to the accompanying drawings.

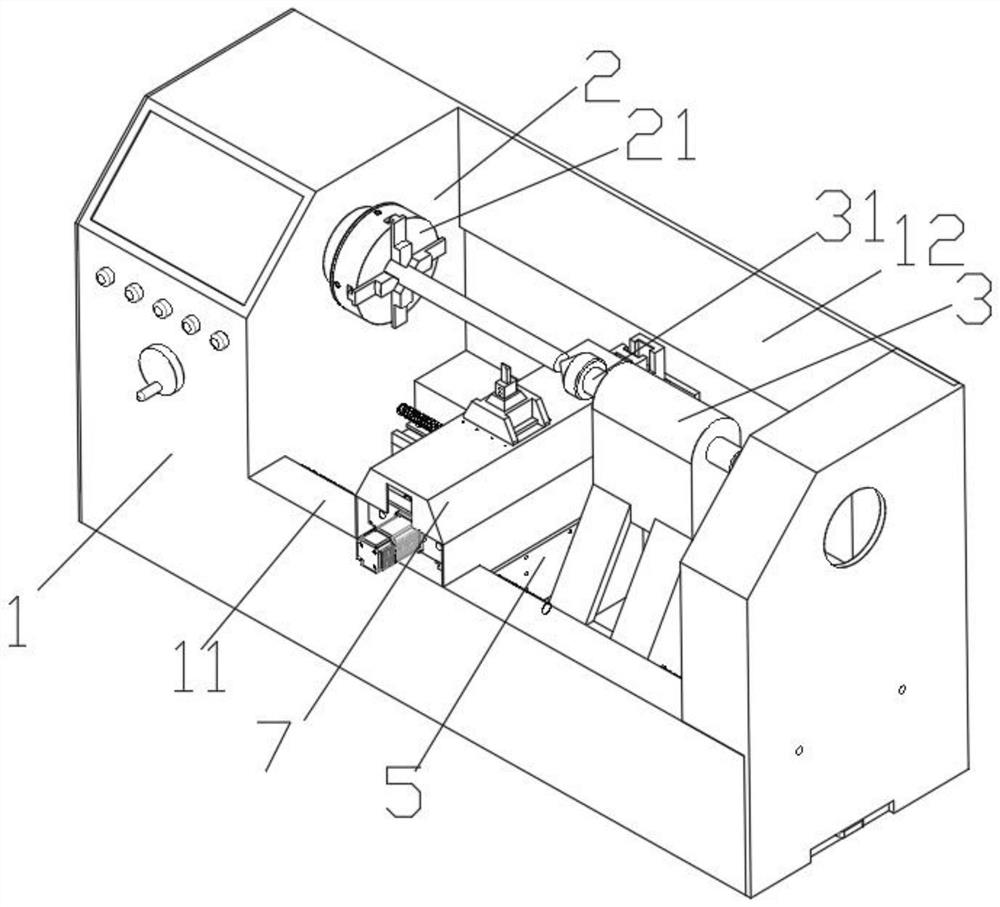

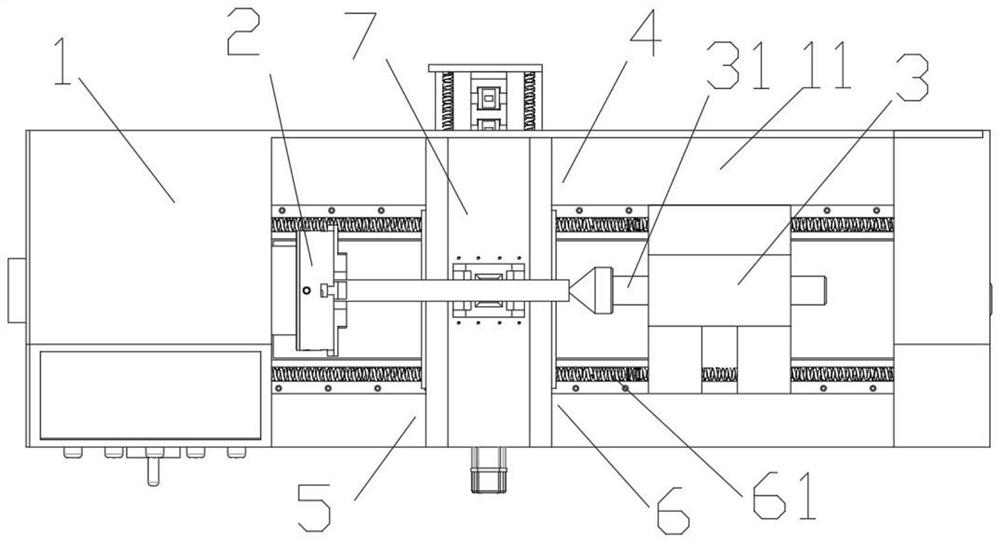

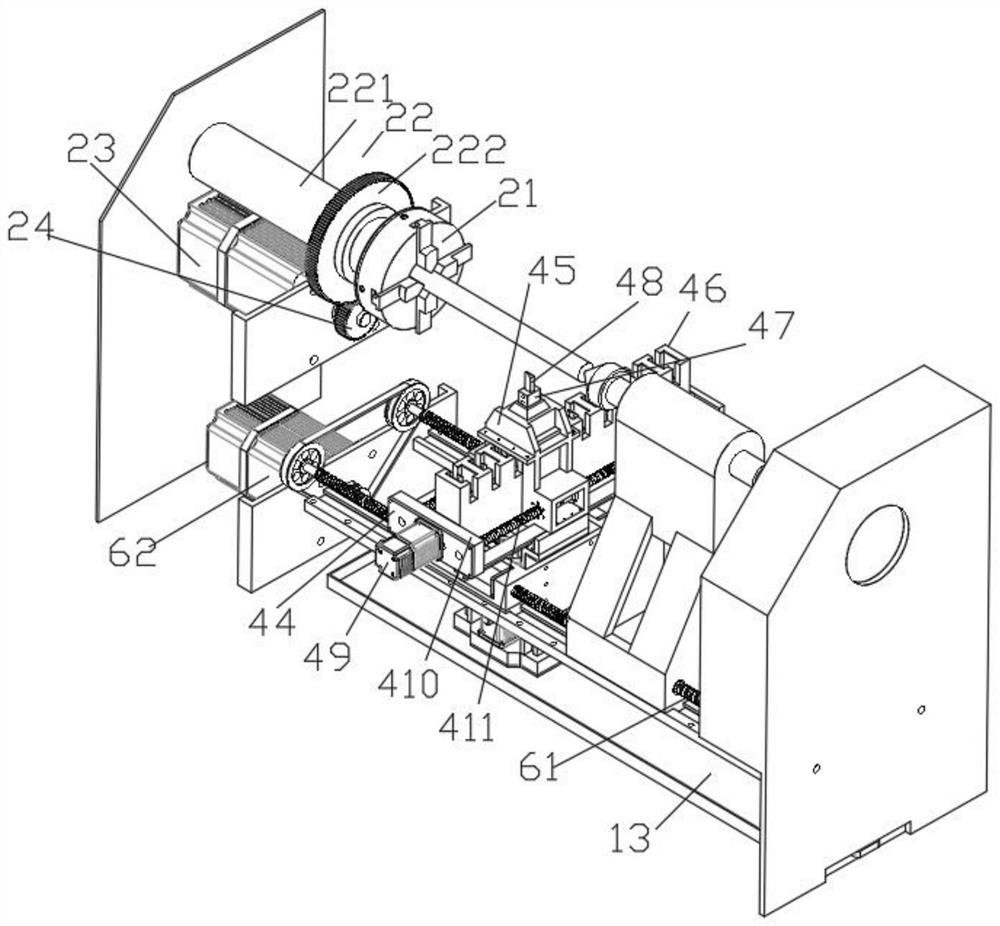

[0040] In this embodiment, a kind of CNC lathe with alternate tool post, including

[0041] The casing 1 includes two mutually symmetrical sliding bases 11 in the right-view axial direction of the casing 1, and the other end of the front-view axial direction of the casing 1 is connected with a protective shell 12;

[0042] The grasping mechanism 2 includes a self-centering chuck 21 axially movable on the casing 1, the end of the self-centering chuck 21 is connected with a reduction gear structure 22 arranged in the casing, and the reduction gear structure 22 is connected with the device. Engage with the main shaft transmission gear 24 at the end of the main shaft motor 23;

[0043] The tailstock 3 is arranged on the two sliding bases 11 of the shell 1, and the upper part of the tailstock 3 is connected with a top 31 which cooperates with the self-centering chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com