Fault alarm device for intelligent manufacturing

A fault alarm and intelligent manufacturing technology, which is applied in the direction of using liquid separation agent, cleaning method and utensils, cleaning methods using tools, etc., can solve the problem that the fault alarm device is not sensitive enough, the fault indicator does not have automatic cleaning function, dust accumulation, etc. problems, to avoid random flying, reduce operating steps, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

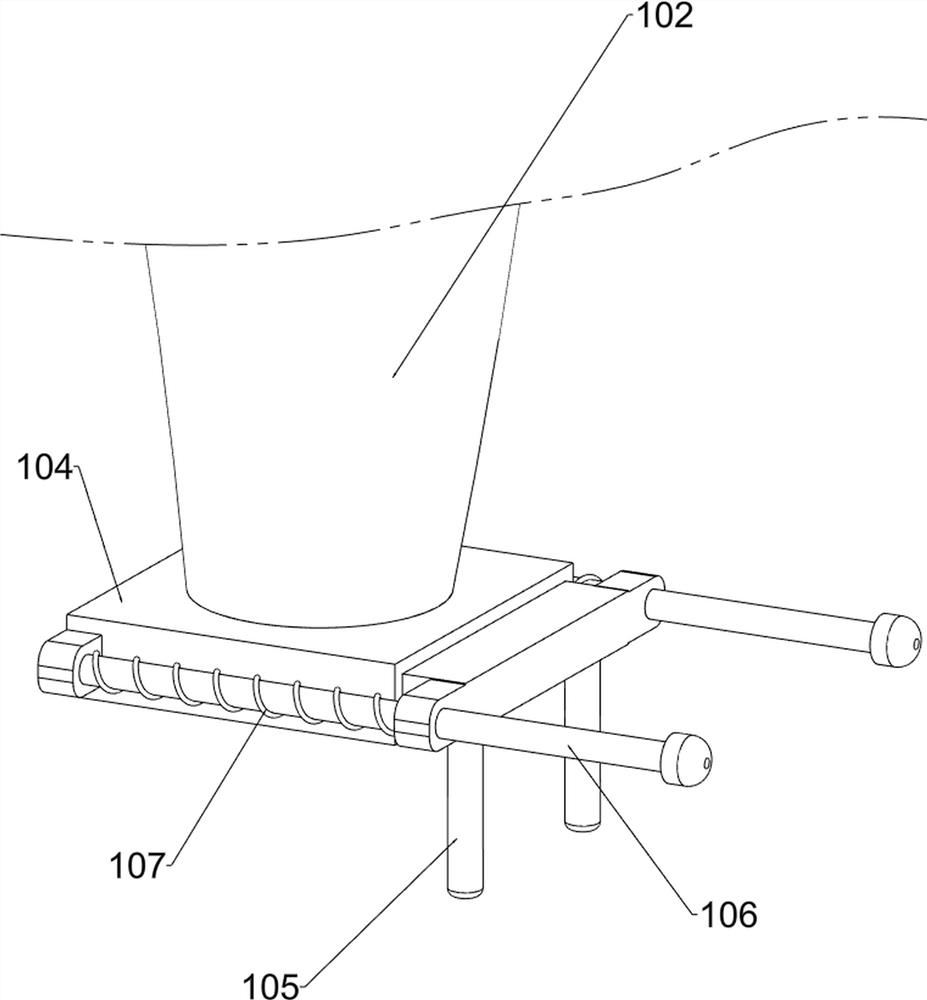

[0073] A fault alarm device for intelligent manufacturing, such as figure 1 As shown, it includes an alarm cabinet 1, a fan 2, a vacuum cleaner 3, a dust collection frame 4, a cover mechanism 5 and a rotating mechanism 6. The fan 2 is arranged on the left side of the lower part of the alarm cabinet 1, and the suction device is installed on the right side of the lower part of the alarm cabinet 1. Dust machine 3, the lower part of the alarm cabinet 1 is slidingly provided with a dust collection frame 4, the middle part of the alarm cabinet 1 is provided with a cover mechanism 5, and the left side of the middle part of the alarm cabinet 1 is provided with a rotating mechanism 6.

[0074] People can use the fault alarm of the present invention. If people want to clean the equipment of the present invention, at first the operator needs to open the rotating mechanism 6. After the rotating mechanism 6 starts, it will drive the cover mechanism 5 to operate, and then the present invention...

Embodiment 2

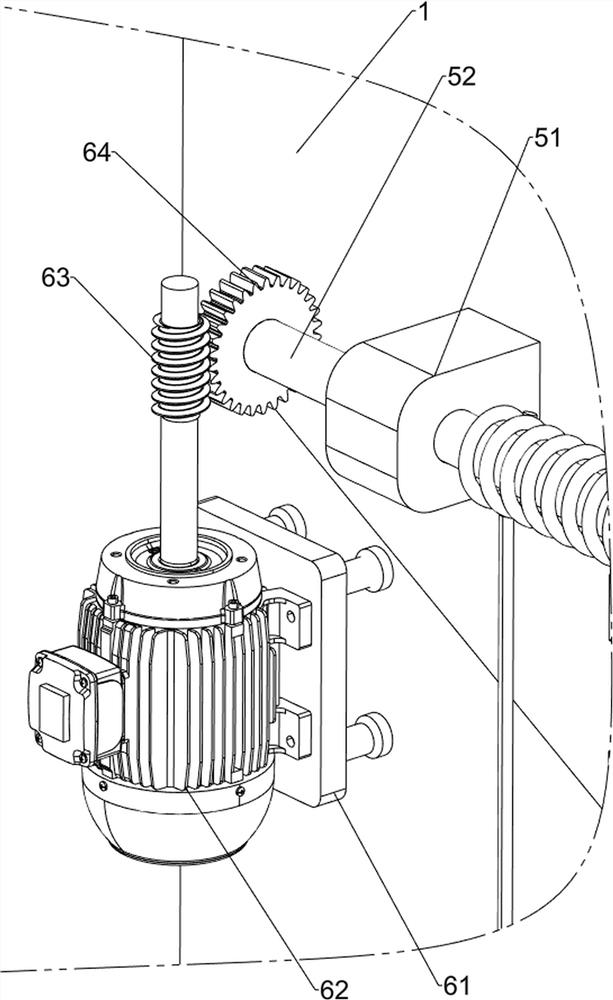

[0076] On the basis of Example 1, such as figure 2 with image 3 As shown, the cover mechanism 5 includes a first support 51, a reel 52, a first rope 53, a first slide rail 54, a support frame 55, a cover cloth 56, a first slide bar 57 and a scroll spring bar 58, and the alarm The left side of the middle part of the cabinet 1 is symmetrically provided with a first support 51 front and rear, and a winding wheel 52 is arranged in a rotating manner between the front and rear two first supports 51, and a first rope 53 is wound on the winding wheel 52, and the middle part of the alarm cabinet 1 is symmetrical front and rear. The first slide rail 54 is provided, and the right side of the middle part of the alarm cabinet 1 is symmetrically provided with a support frame 55 front and rear. Between the two support frames 55, a volute spring rod 58 is rotatably arranged, and a cover cloth 56 is wound on the volute spring rod 58. One end of the covering cloth 56 is provided with a first...

Embodiment 3

[0081] On the basis of Example 2, such as Figure 4-8 Shown, also comprise cleaning mechanism 7, and cleaning mechanism 7 comprises first slide bar 71, second slide bar 72, second support 73, rotating wheel 731, second rope 74, hairbrush 75, the 3rd spring 78. The first sliding sleeve 76 and the first connecting rod 77. The upper part of the alarm cabinet 1 is symmetrically provided with the first sliding rod 71 front and rear, and the second sliding rod 72 is provided slidingly between the two first sliding rods 71. A third spring 78 is connected between the slide bar 71 and the second slide bar 72, the second slide bar 72 bottom is provided with a hairbrush 75, and the alarm cabinet 1 top is provided with a first sliding sleeve 76, which slides on the first sliding sleeve 76. A first connecting rod 77 is provided, and a second bracket 73 is arranged symmetrically front and rear on the left side of the upper part of the alarm cabinet 1, and a rotating wheel 731 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com