Saw blade tooth end steel inlaying equipment for hardware tool machining

A technology of hardware tools and saw blades, which is applied in the field of steel-inlaid equipment for saw blade tooth ends used in hardware tool processing, and can solve problems such as difficult fixation, difficulty in inlaying steel work, unbearable human body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A saw blade tooth end steel inlaid equipment for hardware tool processing, such as figure 1 As shown, it includes a mounting frame 1, a mounting plate 2, a cylinder 3, a fixing mechanism 4 and a cogging mechanism 5. The top of the mounting frame 1 is provided with a mounting plate 2, the bottom of the mounting frame 1 is provided with a cylinder 3, and the right side of the mounting frame 1 is provided with a There is a fixing mechanism 4, and the right side of the top of the mounting plate 2 is provided with an inlay mechanism 5.

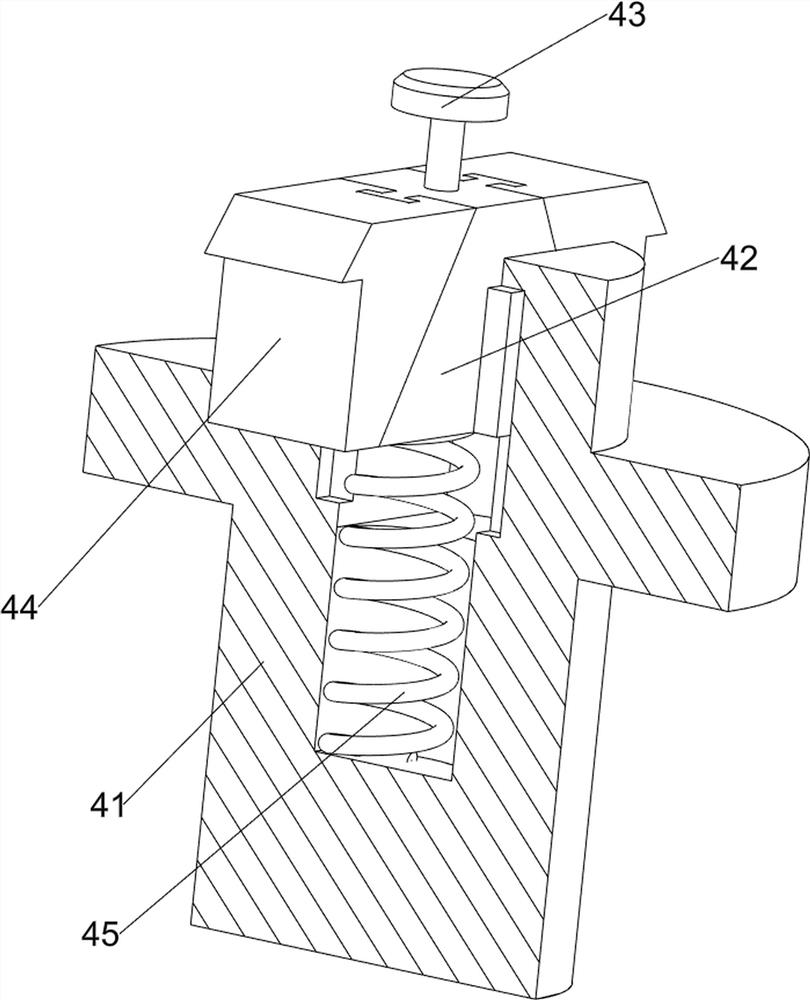

[0069] like figure 2 and image 3 As shown, the fixing mechanism 4 includes a fixing rod 40, a rotating shaft 41, a first inclined block 42, a clamping button 43, a first clamping block 44 and a first spring member 45, and the right side of the mounting frame 1 is provided with a fixing rod 40, which is fixed Bar 40 right side rotation type is provided with rotating shaft 41, and the sliding type in rotating shaft 41 is provided with the ...

Embodiment 2

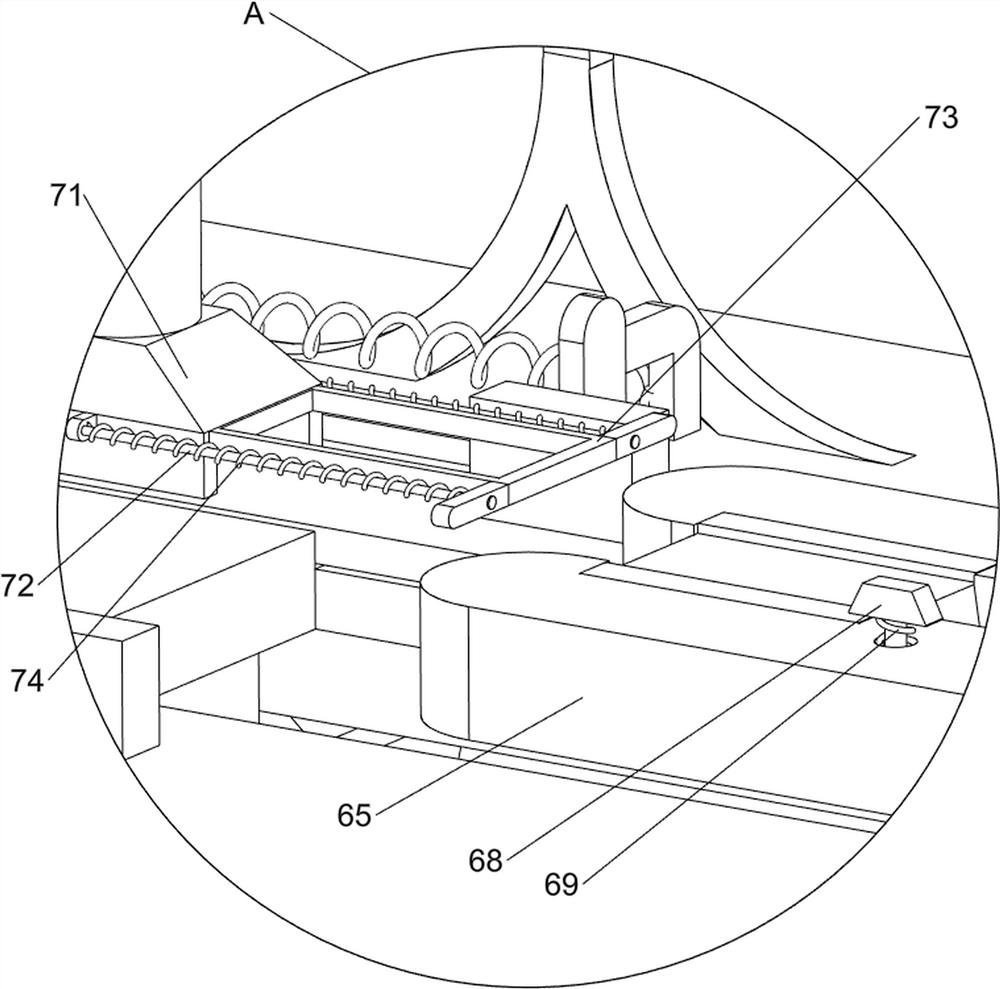

[0073] On the basis of Example 1, such as Figure 5 As shown, a tooth feeding mechanism 6 is also included, and the tooth feeding mechanism 6 includes a connecting frame 60, a first sliding block 61, a second inclined block 62, a third spring member 63, a second sliding block 64, and a second clamping block 65 , the fourth spring part 66, the second rocker 67, the third inclined block 68, the fifth spring part 69, the second stopper 610, the mounting block 611 and the sixth spring part 612, and the telescopic rod of the cylinder 3 is connected with the connecting frame 60 , the left side of the connecting frame 60 is provided with a first slider 61, the first slider 61 is slidably matched with the installation frame 1, and the first slider 61 is slidably provided with a second slanted block 62, and the second slanted block 62 is connected to the first slanted block 62. Two third spring members 63 are connected between one slide block 61, and a second slide block 64 is slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com