Bendable light and thin tempered glass and preparation method thereof

A tempered glass and melting glass technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of increasing glass strength and not being seen, so as to enhance glass strength, prevent cracks, and increase wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

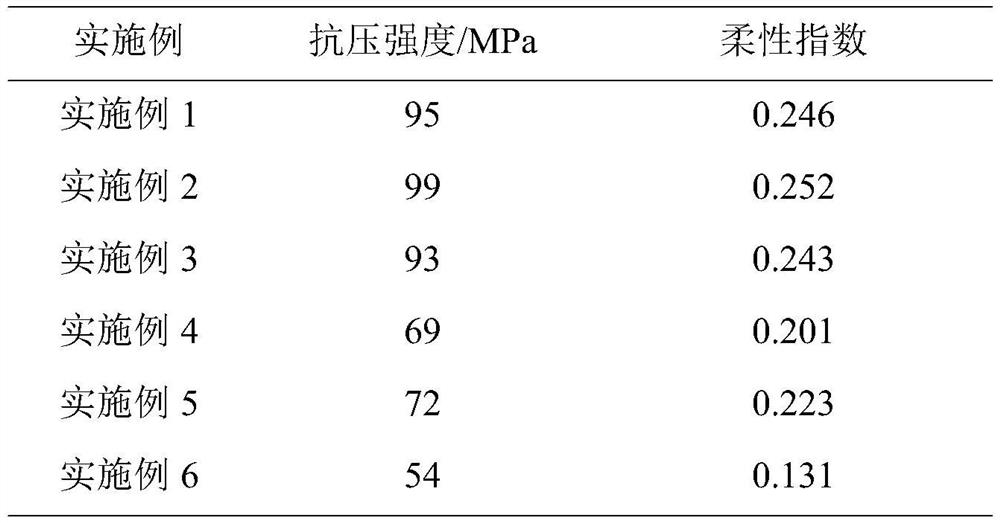

Examples

Embodiment 1

[0038] S1: Preparation of glass material:

[0039] Pb to be weighed 3 o 4 , B 2 o 3 , SiO 2 Ultrasonic dispersion in deionized water, dispersed to a dust-free suspension; transferred to a vacuum box, set the temperature at 80 ° C for 3 hours to remove free water, and the obtained agglomerated lumps were ball milled and sieved with a 200-mesh sieve; The obtained powder is placed in an atmosphere furnace, and the temperature is set at 300°C to dry for 30 minutes to remove capillary water and crystal water; take it out, and add K 3 PO 4 Mix evenly, fill in the carbon film, stir and melt with a tungsten rod, set the reaction temperature at 750°C for 30 minutes; first cool to 400°C at a cooling rate of 15°C / min, then slowly cool at a cooling rate of 2°C / min to Room temperature; the obtained glass is crushed into a powder smaller than 100 μm, added to the methanol-ethanol mixture of the dispersion medium, milled and dispersed with a mixed ZrO ball, the set speed is 240rmp, the...

Embodiment 2

[0050] S1: Preparation of glass material:

[0051] Pb to be weighed 3 o 4 , B 2 o 3 , SiO 2 Ultrasonic dispersion in deionized water, dispersed to a dust-free suspension; transferred to a vacuum box, set the temperature at 100 ° C for 3 hours to remove free water, and the obtained agglomerated lumps were ball milled and sieved with a 400-mesh sieve; The obtained powder was placed in an atmosphere furnace, and the temperature was set at 400°C to dry for 30 minutes to remove capillary water and crystal water; take it out, and add K 3 PO 4 Mix evenly, fill in the carbon film, stir and melt with a tungsten rod, set the reaction temperature to 750°C and react for 30 minutes; first cool to 410°C at a cooling rate of 15°C / min, and then slowly cool at a cooling rate of 2°C / min to Room temperature; the obtained glass is crushed into a powder smaller than 100 μm, added to the methanol-ethanol mixture of the dispersion medium, milled and dispersed with a mixed ZrO ball, the set spe...

Embodiment 3

[0062] S1: Preparation of glass material:

[0063] Pb to be weighed 3 o 4 , B 2 o 3 , SiO 2 Ultrasonic dispersion in deionized water, dispersed to a dust-free suspension; transferred to a vacuum box, set the temperature at 90 ° C for 3 hours to remove free water, and the obtained agglomerated lumps were ball milled and sieved with a 300-mesh sieve; The obtained powder is placed in an atmosphere furnace, set the temperature at 350°C and dried for 30 minutes to remove capillary water and crystal water; take it out, add K 3 PO 4Mix evenly, fill in the carbon film, stir and melt with a tungsten rod, set the reaction temperature to 750°C and react for 30 minutes; first cool to 405°C at a cooling rate of 15°C / min, and then slowly cool at a cooling rate of 2°C / min to Room temperature; the obtained glass is crushed into a powder less than 100 μm, added to the methanol-ethanol mixture of the dispersion medium, milled and dispersed with a mixed ZrO ball, the set speed is 250rmp, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com