Efficient crushing food processor

A food processing machine, high-efficiency crushing technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, grain processing, etc., can solve the problems of low crushing efficiency, failure to achieve fast packaging and efficient production, and incomplete crushing, so as to ensure cleanliness Hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

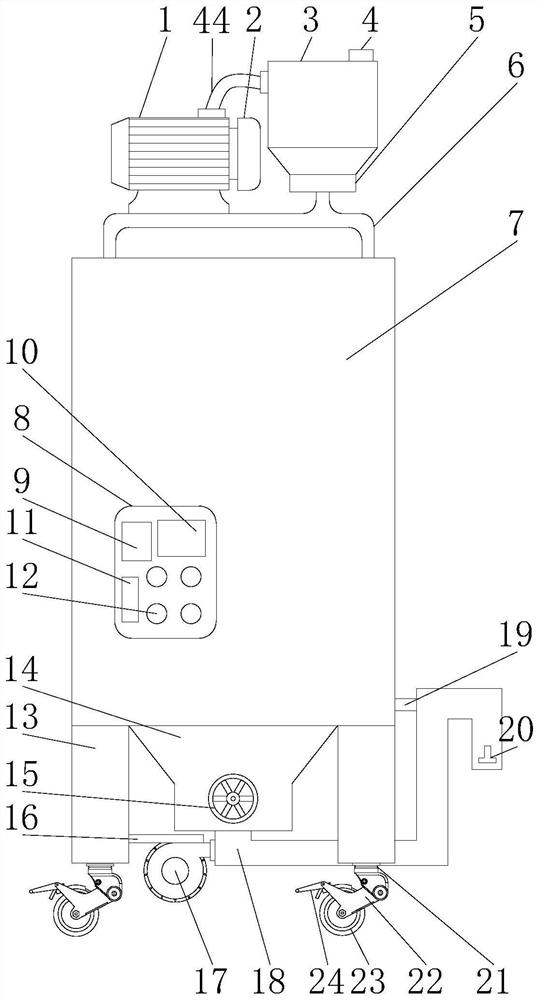

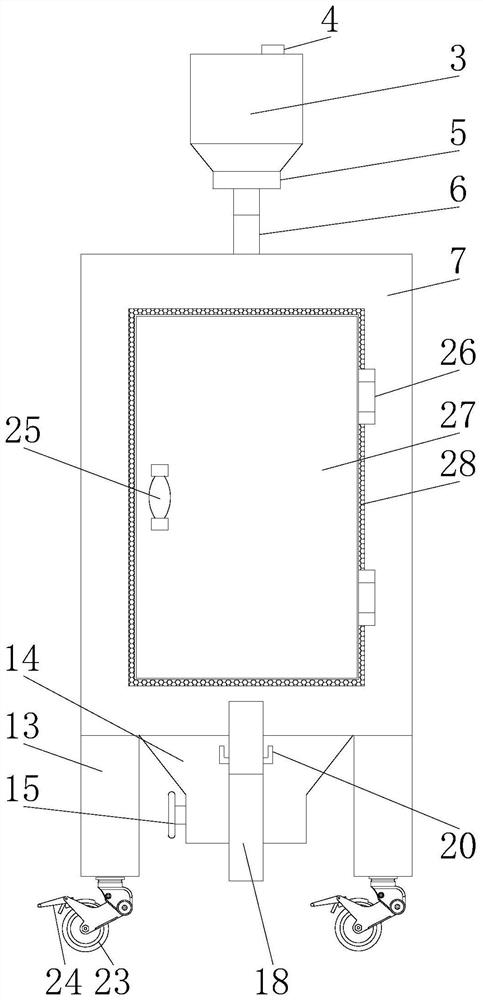

[0029] Such as Figure 1 - Figure 6 As shown, the present invention provides an efficient and pulverized food processing machine, including a pulverket 7, the top of the pulverizer 7 penetrates the water pipe 6, and the top of the water pipe 6 is fixedly mounted with a water port 5, and the top of the water port 5 is fixedly mounted. The cleaning box 3, the top of the cleaning box 3 is fixedly mounted, and the injection port 4 is fixed, and the on-axis of the injection port 4 is fixedly connected to the pressurizing pipe 44, and one end of the pressurizing pipe 44 is fixedly connected to the cleaning pump 1, the right side of the cleaning pump 1 is fixed. A heat sink 2 is mounted, the bottom portion of the pulverizer 7 is fixedly mounted, and the bottom portion of the discharge port 14 is fixedly connected to the air tube 18, and the left side of the air tube 18 is fixedly mounted.

[0030] In the present embodiment, the cleaning agent inside the cleaning tank 3 is transmitted to ...

Embodiment 2

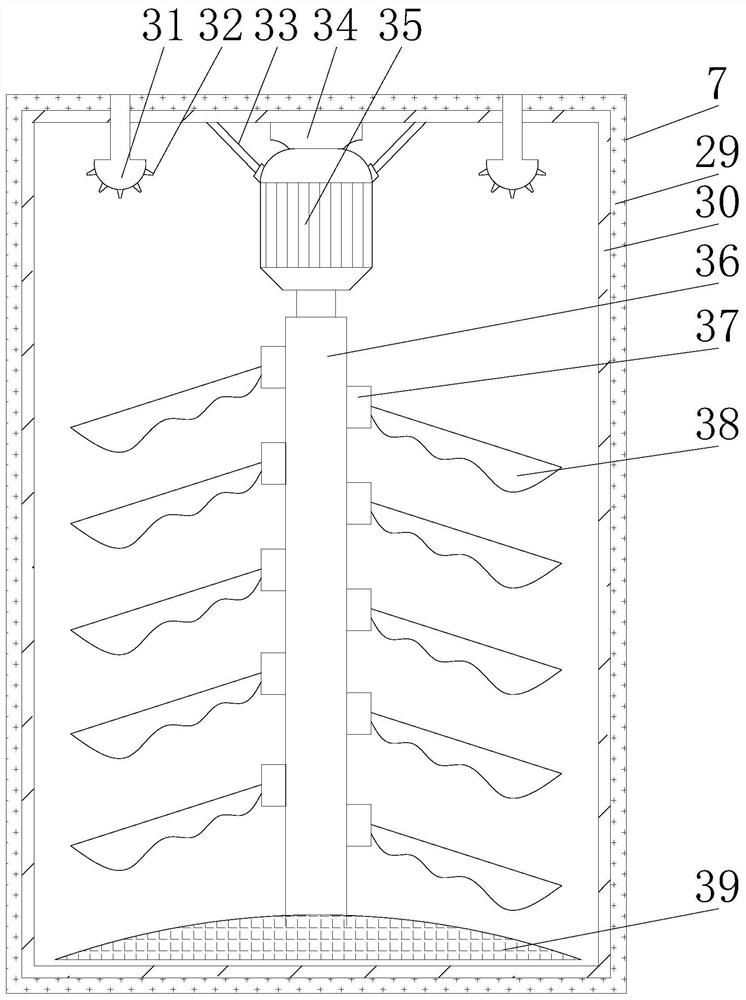

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, in the basis of the first embodiment, the present invention provides a technical solution: the inner top of the pulverizer 7 penetrates the water pipe 6, which mainly acts on the delivery cleaning agent, and the bottom of the water pipe 6 is provided with nozzle 31, which is mainly The bottom of the spray head 31 is evenly distributed in the bottom of the water pressure, and the nozzle 32 is applied mainly to the discharge of the cleaning agent, and the upper left side of the water pipe 6 is fixedly mounted, and the upper portion of the stabilizer is fixedly mounted, and the main function is mainly In the water tank, the inner wall of the pulverizer 7 is provided with a collision layer 30, which mainly acts on preventing the inner wall of the impact protection, and the outer side of the collision layer 30 is sprayed with a preventive layer 29, which mainly acts on preventing corrosion, fan 17 The top ...

Embodiment 3

[0036] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 As shown in the basis of Example 1, Example 2, the present invention provides a technical solution: the front surface of the pulverizer 7 is fixedly mounted, and the front surface of the controller 8 is provided with a leakage protector 9, its main function. In the right side of the leakage protector 9, the right side of the leakage protector 9 is provided with the display screen 10, and the right side of the switch 11 is provided, and the bottom fixed mounting of the crushing case 7 is fixed. The inlet 14, the inner side of the discharge port 14 is provided with a web 42, and the center of the tap plate 42 penetrates through the bearing, the outer wall of the bearing is wound with the transmission belt 43, and the bottom of the transmission belt 43 is wound with a bearing, and the bearing is wrapped in the discharge port 14. The outer wall, the front surface of the discharge port 14 is provided with the strob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com