Phase change radiator with liquid storage structure

A liquid storage structure and heat sink technology, which is applied in the construction parts of electrical equipment, cooling/ventilation/heating transformation, electrical components, etc., can solve the problem of high surface temperature of heat dissipation chips, achieve stable temperature and avoid overheating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

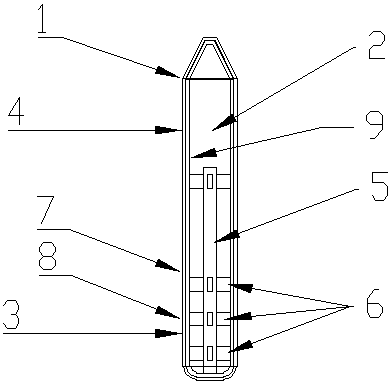

[0013] Such as figure 1 Shown: a heat pipe 1 with a liquid storage structure, a liquid storage structure 5 is installed between the evaporation end 3 and the condensation end 4 of the phase change chamber 2, the liquid storage structure 5 is a capillary porous structure, and one end of the liquid storage structure 5 There are multiple contact points 6 in contact with the evaporating end 3 , so that the liquid can directly flow back to each area of the evaporating end 3 without returning to the core area 8 through the edge area 7 . One end of the liquid storage structure 5 is in contact with the liquid return channel 9 from the condensing end 4 to the evaporating end 3, and can replenish liquid.

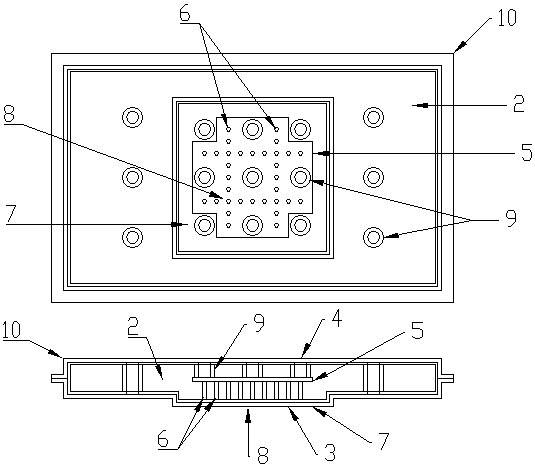

[0014] Such as figure 2 Shown: a vapor chamber 10 with a liquid storage structure, a liquid storage structure 5 is installed between the evaporation end 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com