Watch dial plate convex punching processing technology

A processing technology and dial technology, applied in the field of watch dial embossing processing technology, can solve the problems of difficult operation, low stapling efficiency, affecting the service life of the watch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

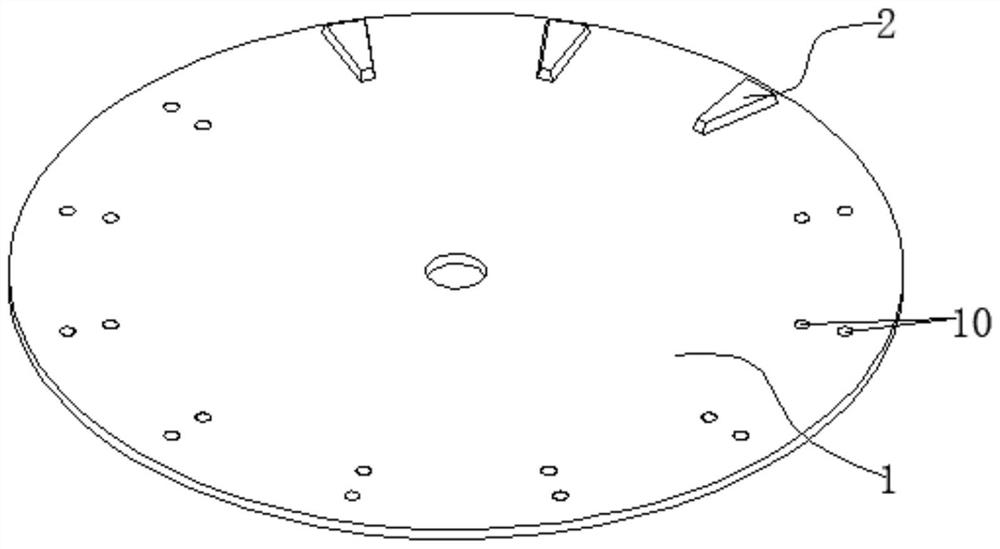

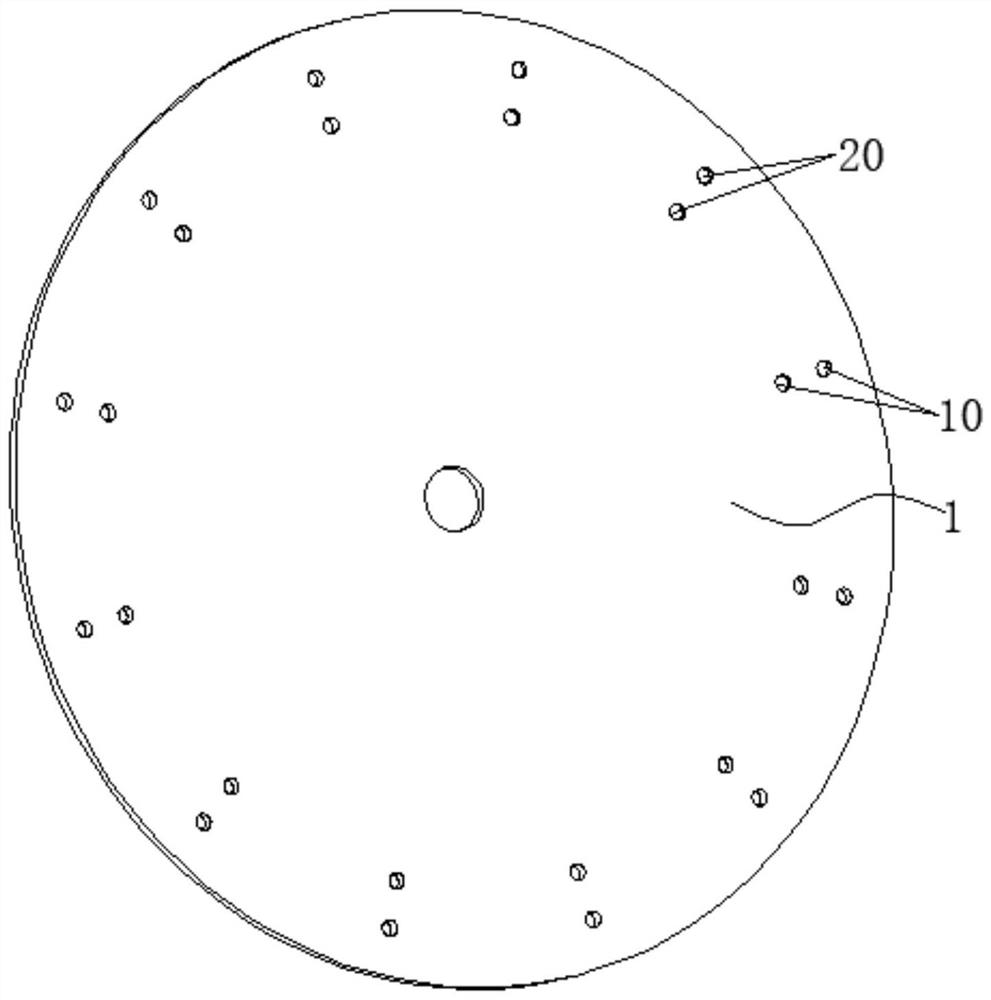

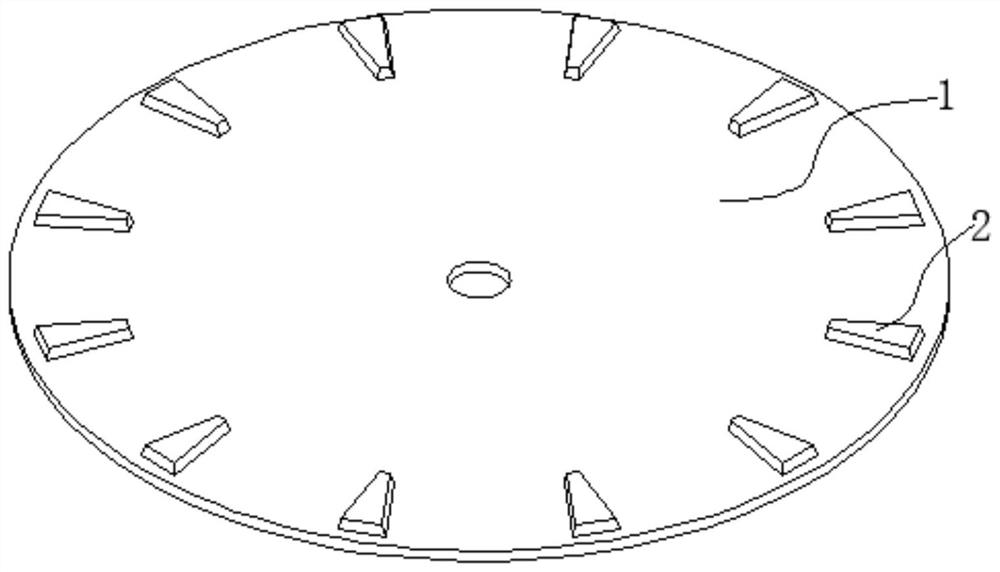

[0044] Compared with the traditional preparation process of using glue to fix the hour hand nail 2, the watch dial embossing processing technology adopts a stamping die to punch the dial blank 1 to obtain the hour hand nail 2, or adopts a cold extrusion operation to directly make the shading It is extruded together with the hour hand nail 2, so that the dial shading and the hour hand nail 2 are integrally formed, reducing the drilling of small holes 10 and dispensing processes, and eliminating the need to purchase the hour hand nail 2, which saves costs, and the hour hand nail 2 will not fall off. The processing procedure is reduced, the process is simple and reliable, and the service life of the watch is longer.

[0045] In the present invention, the grinding process is placed behind the painting process, the nail batching process is set behind the grinding process, and the electroplating hour hand nail 2 process is placed at the end, realizing the polishing of the paint on th...

Embodiment 2

[0047] On the basis of Example 1, the dial blank 1 in the step 1 is disc-shaped or rectangular or waist-shaped; in the step 3, the hour hand nail 2 is punched beyond the surface of the dial blank by 0.3mm; in the step 5 The grinding depth is 0.05mm; the shape and pattern cut out in the step 6 are triangular prism or quadrangular prism; the electroplating background color in the step 2 includes electroplating silver, electroplating nickel, electroplating copper, While coloring, prevent the dial blank 1 from being oxidized; the electroplating hour hand nail 2 in the step 7 includes electroplating silver, electroplating nickel, electroplating copper, and electroplating rose gold. While coloring the hour hand nail 2, prevent the hour hand nail from being oxidized. 2 is oxidized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com