Preparation method of important intermediate of roxadustat

A technology for roxadustat and its intermediates, which is applied in the field of preparation of important intermediates of roxadustat, which can solve the problems of high requirements on site and safety, difficulty in popularizing and producing raw materials of roxadustat in large quantities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

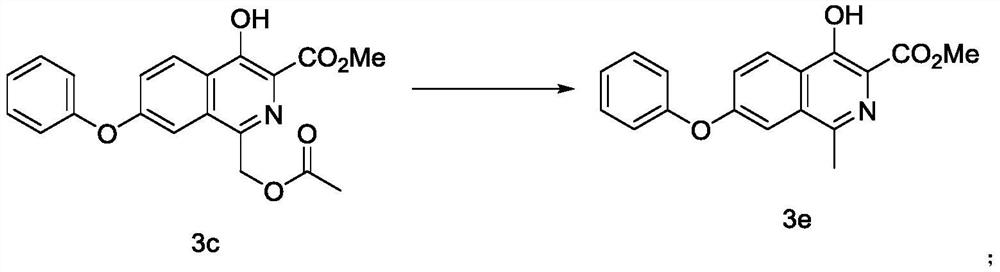

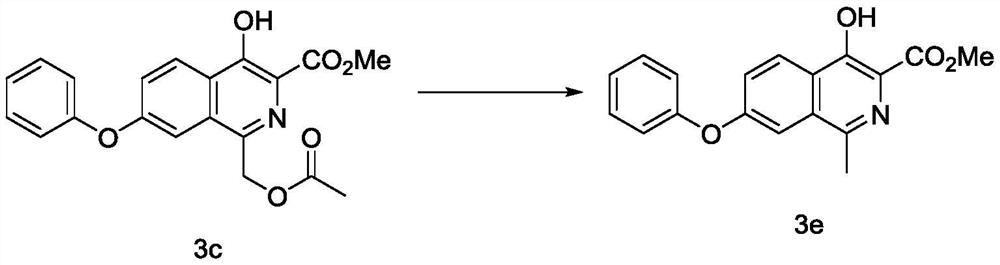

[0027] Take the raw material 3c (1g, 2.7mmol), add 20ml of tetrahydrofuran, add iron powder (0.89g, 15.9mmol), add acetic acid (3.0g, 50mmol) dropwise at room temperature, heat at 60°C for 12 hours after the addition, and detect the reaction of the raw material by TLC Complete, cool down to room temperature, filter with Celite pad, wash with 10ml THF, collect the filtrate, add 180ml water dropwise to the filtrate, solid precipitates, filter with suction, and dry to obtain 0.75g of the final product 3e, yield: 90%.

Embodiment 2

[0029] Take raw material 3c (1g, 2.7mmol), add 20ml of tetrahydrofuran, add zinc powder (0.89g, 13.6mmol), add acetic acid (1.7g, 28.3mmol) dropwise at room temperature, heat at 60°C for 4 hours after the addition, and detect the raw material by TLC After the reaction was complete, cool down to room temperature, filter with diatomaceous earth, wash with 10ml of THF, collect the filtrate, add 180ml of water dropwise to the filtrate, the solid precipitated, filtered with suction, and dried to obtain 0.77g of the final product 3e, yield: 93%.

Embodiment 3

[0031] Take raw material 3c (1g, 2.7mmol), add 10ml of N,N-dimethylformamide, add zinc powder (0.89g, 13.6mmol), add acetic acid (1.7g, 28.3mmol) dropwise at room temperature, and heat for 40 React at ℃ for 4 hours, TLC detects that the reaction of the raw materials is complete, cool down to room temperature, filter with diatomaceous earth, wash with 2ml of N,N-dimethylformamide, collect the filtrate, add 180ml of water dropwise to the filtrate, the solid precipitates, filter with suction, After drying, 0.76 g of the final product 3e was obtained, yield: 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com