Method of optimizing recovery process for wastewater in esterification tower used in ethyl acetate production

A technology for ethyl acetate and process optimization, which is applied in the field of wastewater extraction process optimization in the esterification tower in the production of ethyl acetate, can solve the problems of low extraction efficiency, inconvenient collection and storage, and poor filtering effect, so as to reduce pollution, Ensure recovery efficiency and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

[0036] In the picture:

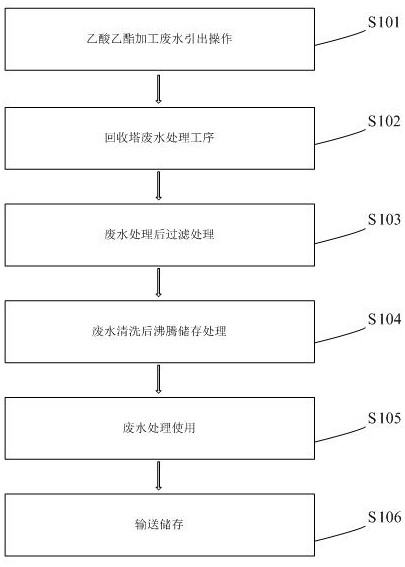

[0037] as attached figure 1 shown

[0038] A method for optimizing the wastewater extraction process in the esterification tower in the production of ethyl acetate specifically comprises the following steps:

[0039] S101: Ethyl acetate processing wastewater extraction operation, the wastewater generated in the ethyl acetate production process is led to the recovery tower through pipelines, and the wastewater is initially filtered, and the wastewater can be filtered during the transfer process. The pool is filtered and precipitated to filter out the larger impurities and particles, and then stirred by the agitator, and finally sent to the recovery tower for recovery and treatment;

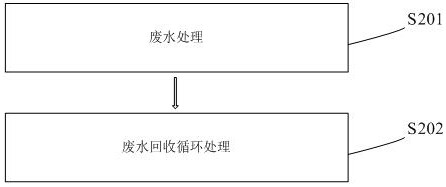

[0040] S102: Recovery tower wastewater treatment process, combined with figure 2 As shown, the specific operation includes the following steps:

[0041] S201: Wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com