Lycium ruthenicum composite microecological preparation product and preparation method thereof

A technology of compounding microecology and Lycium rutabaga, applied in the directions of bacteria, food drying, and food freezing used in food preparation, can solve the problem of reducing the number of active probiotics in microecological preparation products, and the quality and functional problems of microecological preparation products. damage, lack of full activity and nutrients, etc., to achieve the effect of rich product line, low cost, high content of active bacteria and active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

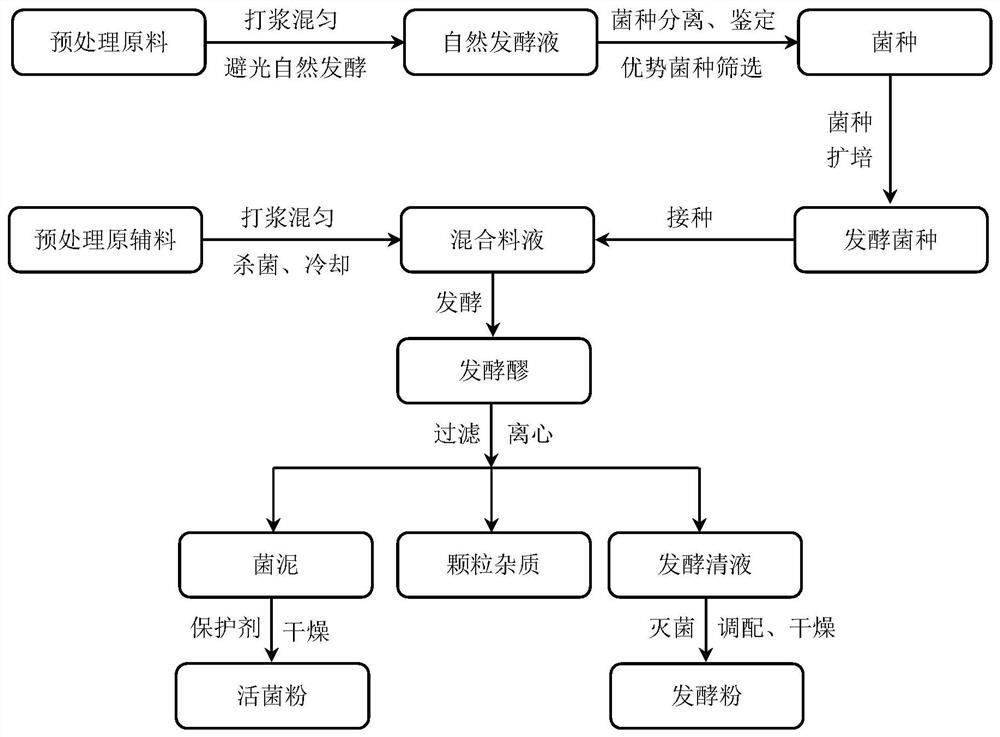

[0049] The preparation method of described composite strain is:

[0050] Take 12 parts of black fruit wolfberry, 8 parts of wolfberry, 5 parts of Juema, 3 parts of Maca, 5 parts of brown sugar, 1 part of seabuckthorn powder, and 80 parts of sterile water;

[0051] Lycium barbarum is cleaned and then rehydrated with sterile water at a mass ratio of 1:4. Maca and Juema are washed and boiled for 40-90 minutes until they become soft. The remaining raw materials are mixed with sterile water and then transferred to Stir well in the sterilized container, seal it, and ferment at 28°C in the dark for 15-25 days;

[0052] Filter the strain fermented liquid of natural fermentation 20d through 4 layers of gauze, and get the filtrate;

[0053] After gradient dilution, take 0.20mL of the diluted solution and spread it on the YEPD solid medium, pick strains of different shapes and inoculate them on the WL solid medium for isolation, and identify the yeasts obtained from the culture;

[005...

Embodiment 1

[0070] The preparation method of the strain.

[0071] combine figure 1 As shown, weigh the raw materials for fermentation: 300g black fruit wolfberry, 200g wolfberry, 125g fern, 75g maca, 125g brown sugar, 25g seabuckthorn powder, 2L sterile water, after washing wolfberry, add 1:4 (mass ratio) without Bacterial water is rehydrated, Maca and Junima are washed and boiled for 60 minutes until they become soft, the processed raw materials are mixed and the remaining sterile water is added, beaten, transferred to a sterilized stainless steel bucket, stirred evenly, sealed, Fermentation was carried out in a dark incubator at 28°C. The fermented liquid of Lycium barbarum black fruit fermented naturally for 20 days was filtered through 4 layers of gauze to obtain the filtrate.

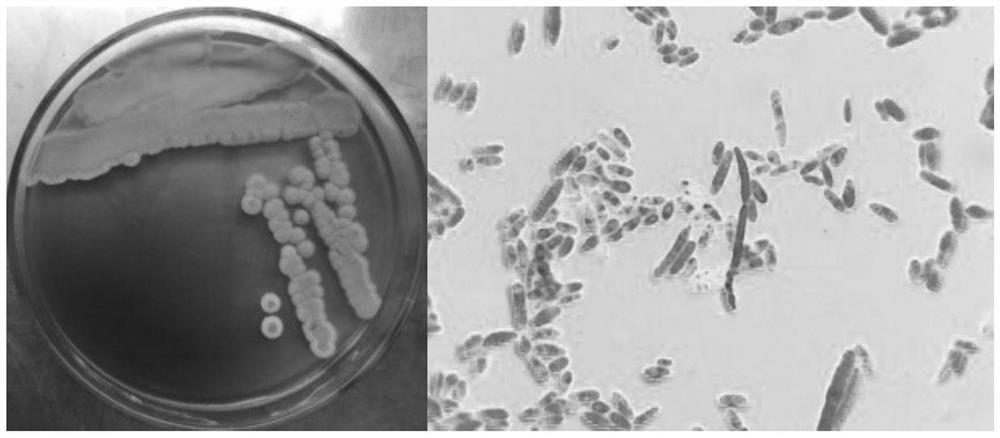

[0072] The filtrate was serially diluted, and 0.20 mL of the diluted solution was spread on the YEPD solid medium, and strains of different forms were picked and inoculated on the WL solid medium for isolati...

Embodiment 2

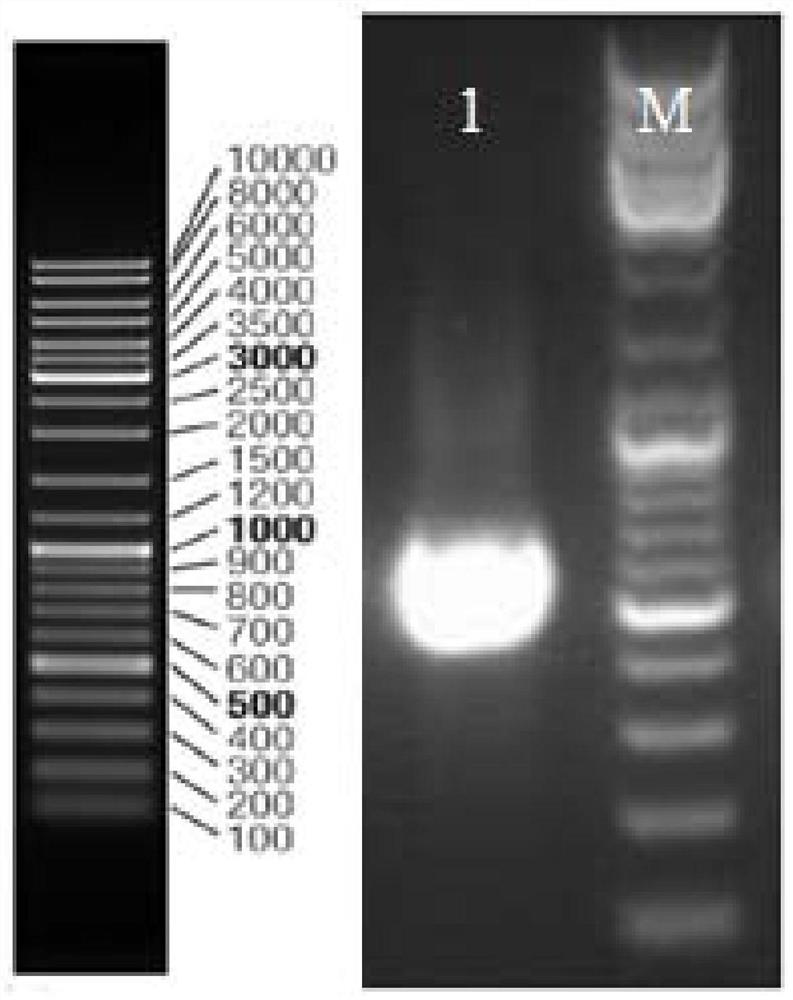

[0076] Bacteria identification.

[0077] 1. Medium preparation:

[0078] MRS solid medium formula: peptone 1g, beef extract 0.5g, glucose 2g, yeast extract powder 0.4g, agar powder 1.5g, Tween 80 100uL, K 2 HPO 4 0.2g, CH 3 COONa 0.5g, (NH 4 ) 3 C 6 h 5 o 7 0.2g, MgSO 4 0.02g, MnSO 4 0.005g, 100mL distilled water, natural pH, sterilized at 121℃ for 20min.

[0079] YEPD solid medium formula: peptone 2g, yeast powder 1g, glucose 2g, agar powder 2g, distilled water 100mL, pH natural, 121°C damp heat sterilization for 20min.

[0080] WL medium formula: tryptone 0.5g, glucose 5.0g, yeast extract powder 0.4g, agar powder 2.0g, KH 2 PO 4 0.055g, KCl 0.0425g, CaCl 2 0.0125g, MgSO 4 0.0125g, FeCl 3 0.0003g, MnSO 4 0.0003g, 0.0022g bromocresol green, 100mL distilled water, natural pH, sterilized at 121℃ for 20min.

[0081] 2. Yeast morphology observation method

[0082] Take 1 mL of the mixed and single fermentation liquid of Lycium barbarum lycium barbarum, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com