Method for producing butyric acid through fermentation of multilinked fiber bed bioreactor system

A bioreactor and fiber bed technology, applied in the field of bioengineering, can solve the problems of difficult industrial scale-up of immobilized fermentation reactors, bioreactor system scale-up, low fermentation efficiency, etc., to achieve large-scale industrial scale-up and shorten delay period, the effect of increasing the concentration of the final product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

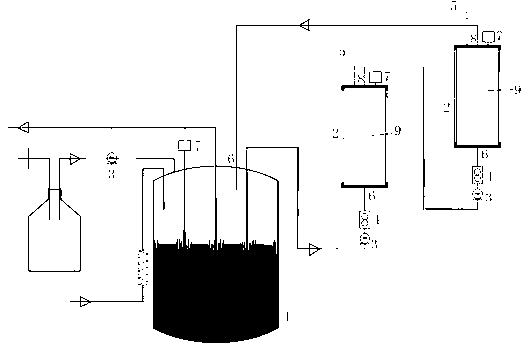

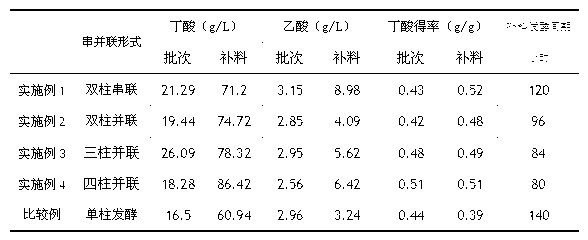

[0023] What this example provides is the process of producing butyric acid by fermentation of two fiber bed bioreactors in series, and the steps are as follows:

[0024] (1) Preparation of multi-fiber bed bioreactor: figure 1 The multi-connected fiber bed bioreactor is a fiber bed bioreactor formed by two fiber bed bioreactors 2 connected in series; a pump 3 and a flowmeter 4 are set on the material inlet and material outlet pipelines of each fiber bed bioreactor, A pH meter 7 and a thermometer 5 are installed in the outlet pipeline of each fiber bed bioreactor. The fermentation state of each fiber bed bioreactor is detected by detection elements such as flow meters, pH meters, and thermometers, and the circulation speed of the fermentation broth is controlled by pumps. Each fiber bed bioreactor is an interlayer packed column composed of concentric inner and outer cylinders. In this example, the volume of each fiber bed filled column is 500mL, and the packed column is made o...

Embodiment 2

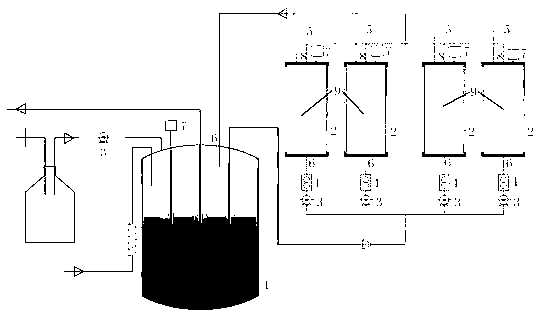

[0029] What this example provides is the technology that produces butyric acid by fermentation of two fiber bed bioreactors in parallel system, and the steps are as follows:

[0030]1) The preparation of the multi-fiber bed bioreactor is the same as in Example 1, the difference is that the multi-fiber bed bioreactor is a fiber bed bioreactor formed by two fiber bed bioreactors 2 connected in parallel; each fiber bed is filled with a column The volume is 500mL, and the filled cylinder is made of glass;

[0031] 2) same as embodiment 1 step 2);

[0032] 3) Same as step 3 of embodiment 1);

[0033] 4) Same as Step 4) of Example 1, using batch fermentation, the final concentration of butyric acid in the fermentation broth was 19.44g / L.

[0034] In this example, when the sugar concentration in the fermentation broth is close to 0, glucose solution is added for fed-batch fermentation, and the final concentration of butyric acid in the fermentation broth is 74.72g / L. The fermentat...

Embodiment 3

[0036] What this example provides is the technology that produces butyric acid by the fermentation of three fiber bed bioreactors in parallel system, and the steps are as follows:

[0037] 1) The preparation of the multi-fiber bed bioreactor is the same as in Example 1, the difference is that the multi-fiber bed bioreactor is a fiber bed bioreactor formed by three fiber bed bioreactors 2 in parallel; each fiber bed is filled with a column The volume is 500mL, and the filled cylinder is made of glass;

[0038] 2) same as embodiment 1 step 2);

[0039] 3) Same as step 3 of embodiment 1);

[0040] 4) Same as step 4) of Example 1, using batch fermentation, the final concentration of butyric acid in the fermentation broth is 26.09g / L.

[0041] In this example, when the sugar concentration in the fermentation broth is close to 0, glucose solution is added to carry out fed-batch fermentation, and the final concentration of butyric acid in the fermentation broth is about 78g / L. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com