Grinding machine for alloy cast steel roller machining

A technology for alloy cast steel and rolls, which is applied in the field of grinding machines for processing alloy cast steel rolls, can solve problems such as difficult removal of black scale, and achieve the effects of avoiding changes in crystal structure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

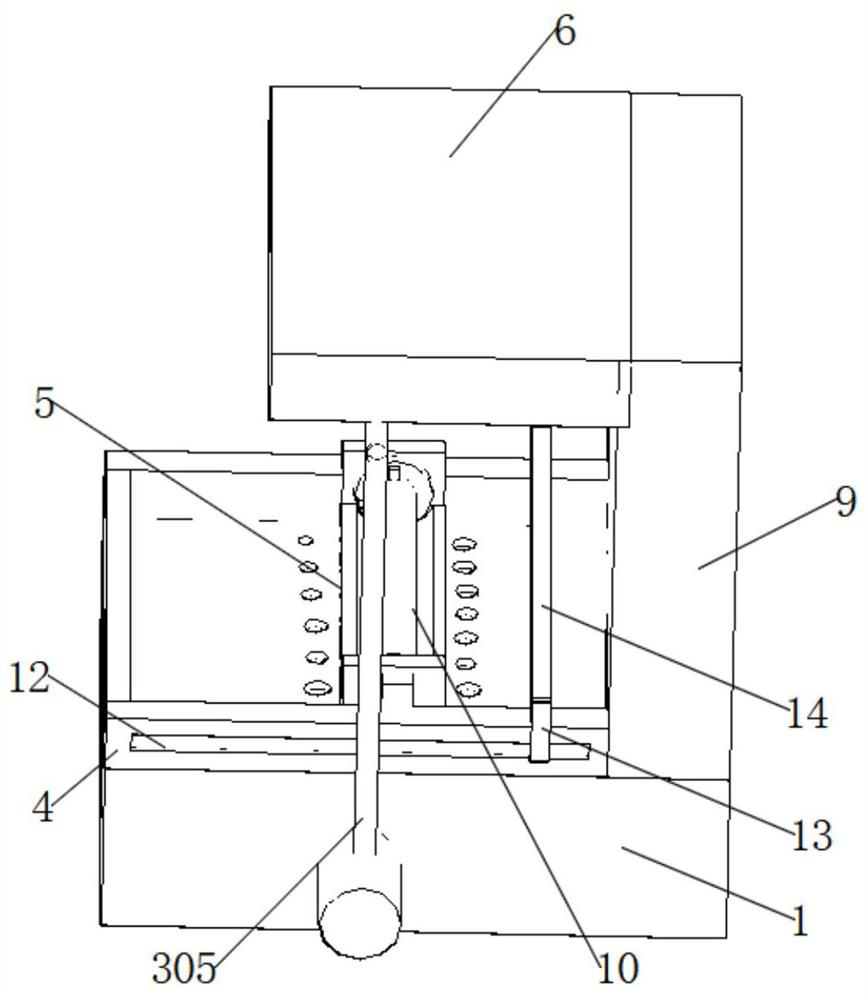

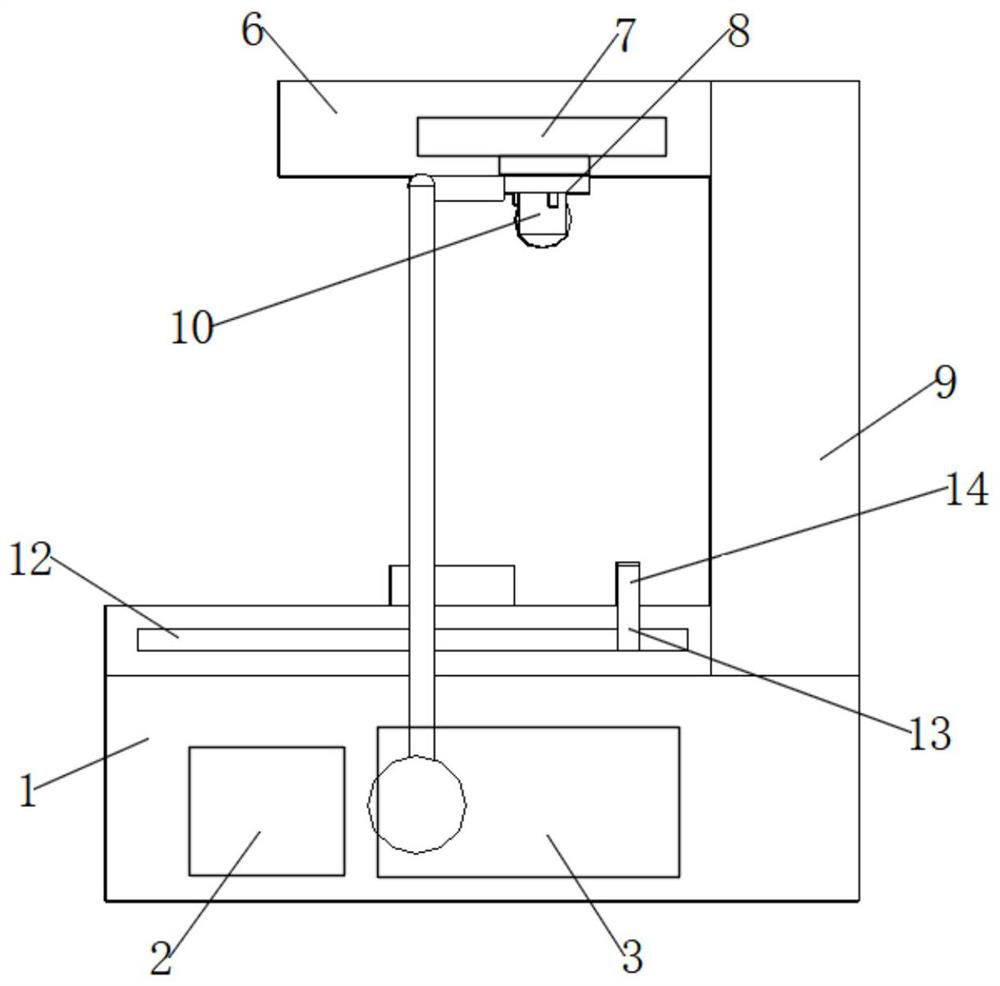

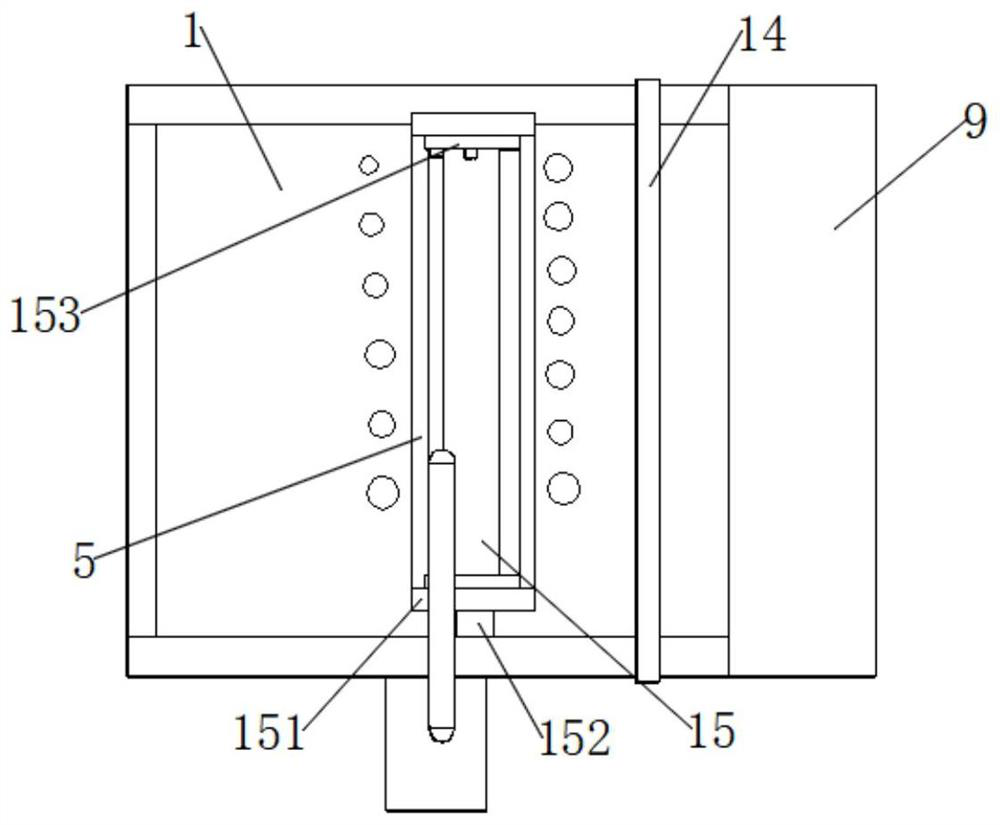

[0033] Such as Figure 1-6 As shown, the embodiment of the present invention provides a grinding machine for processing alloy cast steel rolls, which includes a housing 1, and an electrical box 2 is arranged inside the housing 1 to carry electrical components and control components. The electrical box 2 includes a box body 201, the box The inside of the body 201 is provided with a controller 202 to control the movement of the grinding device. The rotating motor 152, the grinding motor 102, the pump body 304, and the infrared sensor 11 are all connected to the controller 202 with signals. The right side of the device 202 is fixedly connected with a power supply 203 to provide electricity.

[0034] The inside of the housing 1 and the right side of the electrical box 2 are provided with a cooling box 3 to cool the processing parts. The cooling box 3 includes a box shell 301, and the inside of the box shell 301 is provided with a filter screen 302, and the bottom of the filter scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com