Steel-concrete composite structure shear connector, construction method and shear composite structure

A technology of shear connectors and composite structures, which is applied in the fields of building construction connectors, steel-concrete composite structure shear connectors, and shear composite structures, and can solve problems such as residual tensile stress and unfavorable fatigue safety of beam components , to achieve the effect of ensuring fatigue performance, ensuring welding and processing quality, and fixing and stabilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

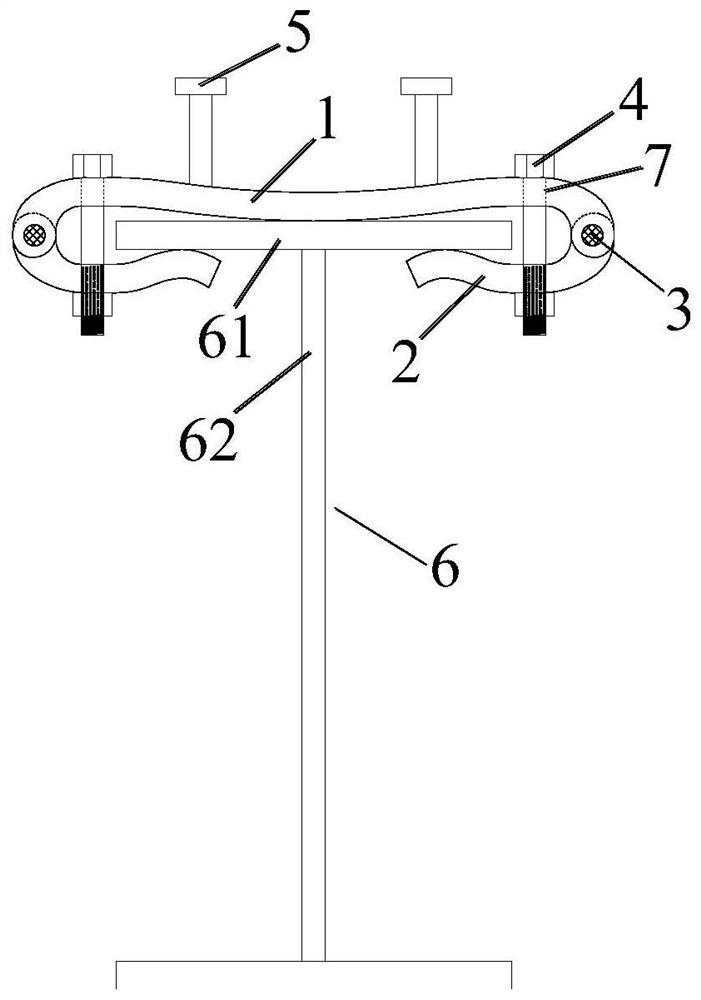

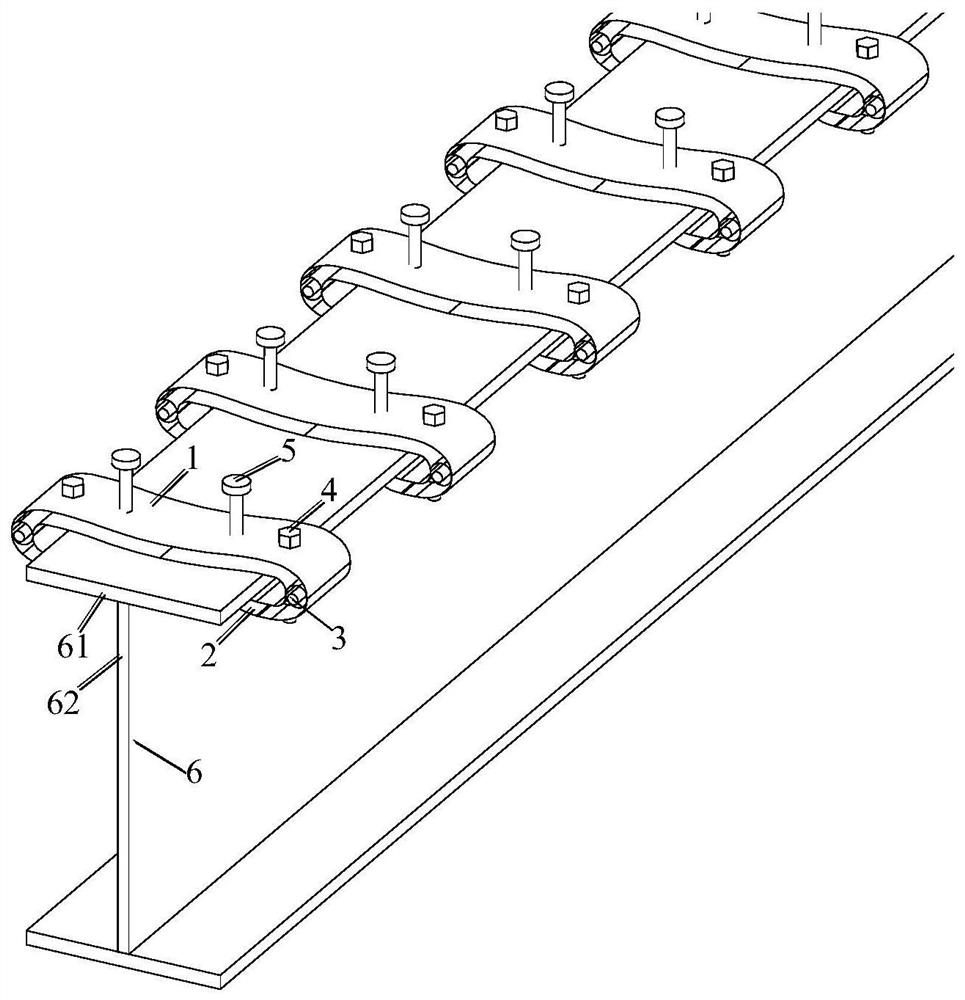

[0030] A steel-concrete composite structure shear connector, comprising an upper splint 1, a lower splint 2, a pin shaft 3, a high-strength bolt 4, a stud 5, and an H-shaped steel beam 6; each side of the upper splint 1 is connected to a The lower splint 2 is hinged, and the lower splint 2 is in the shape of a curved surface. After rotating inwardly around the hinge point, it encloses the flange 61 of the H-shaped steel beam 6; the upper splint 1 and the lower splint 2 are located on the wing. The corresponding parts on the outside of the edge 61 are connected and fastened by the high-strength bolts 4, so that the upper splint 1 and the lower splint 2 clamp the flange 61; Stud 5.

[0031] In this example, see Figure 1-4 , the middle part of the upper splint 1 has a downwardly concave radian, and the part corresponding to the high-strength bolt 4 has an upwardly convex radian, so that the gap between the upper splint 1 and the lower splint 2 at the corresponding part of the h...

Embodiment 2

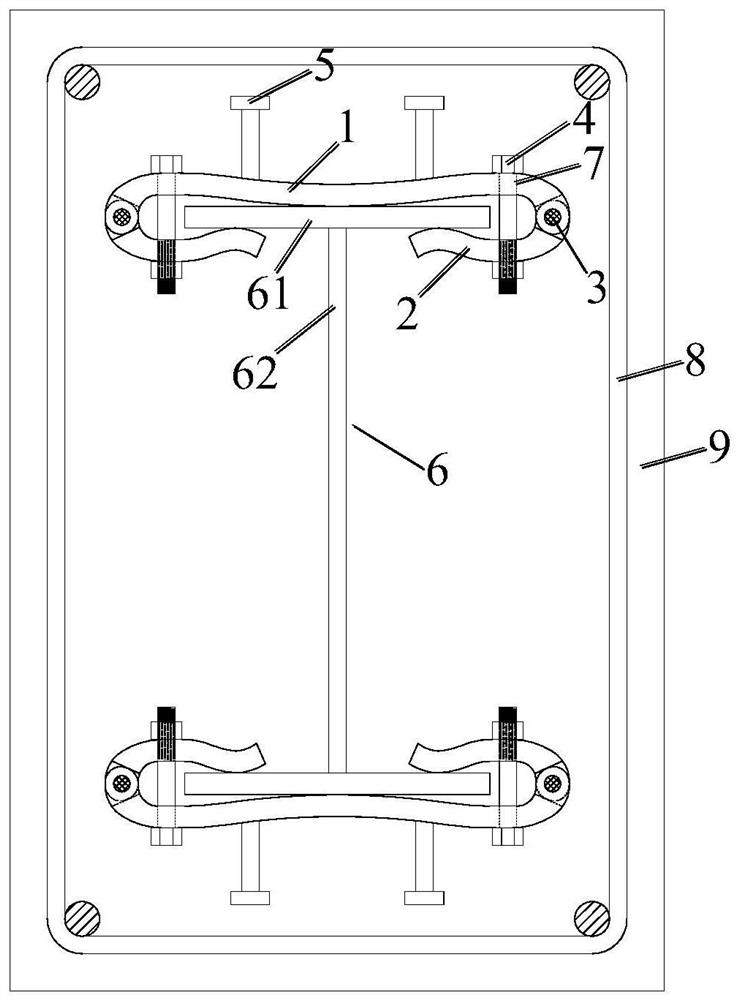

[0043] In this embodiment, the part of the steel-concrete composite structure shear connector and its construction method are the same as the first embodiment.

[0044] For the part of the shear combined structure that is different from embodiment one, the specific description is as follows:

[0045] see Figure 4 , a shear composite structure, the above-mentioned steel-concrete composite structure shear connector is fixedly arranged on the flange 61 of the single end of the H-shaped steel beam 6, the upper splint 1, the stud 5, and the high-strength bolt 4 is pre-embedded and fixed in the concrete beam, so that the web 62 of the H-shaped steel beam is perpendicular to the concrete beam, and the flange 61 is attached to the concrete beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com