A kind of high-strength plastic product medium manganese steel and preparation method thereof

A technology of high-strength plastic product and middle-manganese steel, applied in the field of automobile steel, can solve the problems of uneven structure of medium-manganese steel, large deformation resistance of medium-manganese steel, low strength and plastic product, etc. The effect of rolling deformation resistance and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a high-strength plastic product medium manganese steel, and its preparation method includes:

[0049] 1. Smelt molten steel according to the set composition, and then cast it into a 20kg ingot; the mass percentage of molten steel is: C: 0.26%, Mn: 10.02%, Al: 2.86%, Si: 1.86%, and the balance is Fe and unavoidable of impurities.

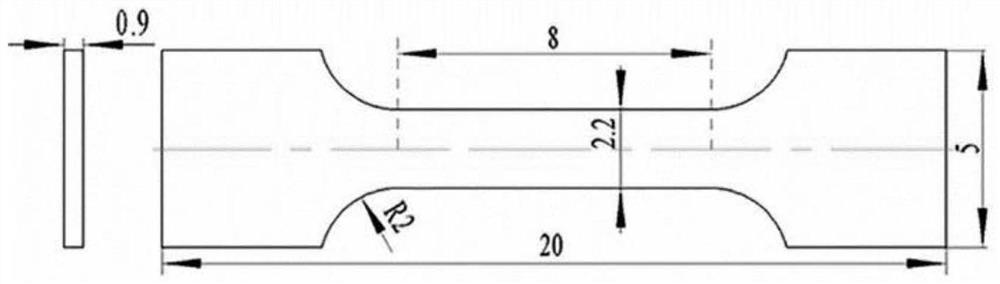

[0050] 2. Heat the ingot to 1200°C, hold it for 2 hours, and then forge it into a slab, then air-cool it to room temperature; use wire cutting technology to wire-cut the slab, and cut a steel plate with a thickness of 3mm.

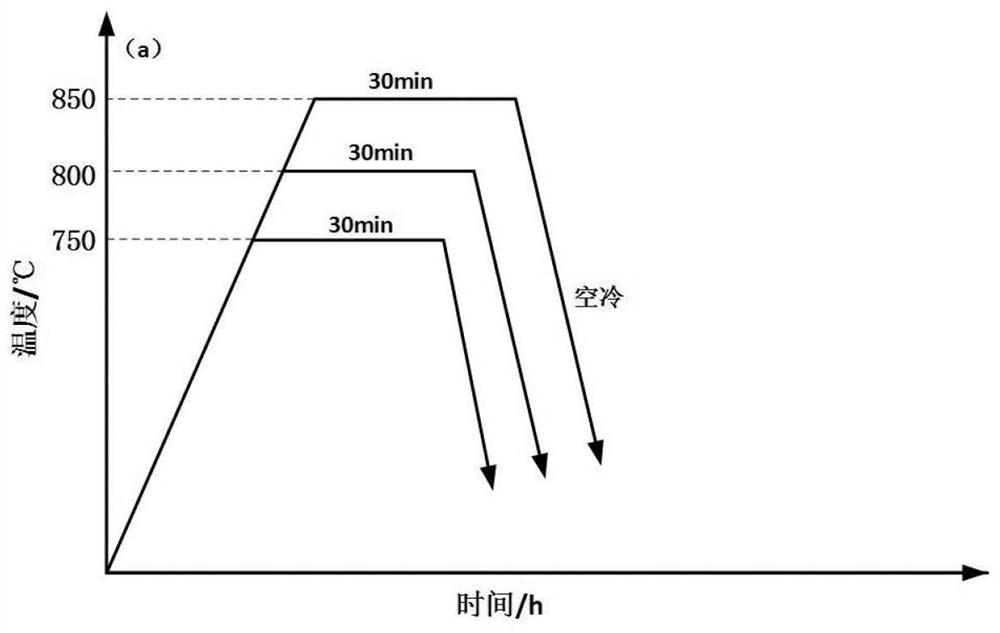

[0051] 3. Heat the steel plate to 400°C for 1 hour, and then carry out three passes of warm rolling, from 3mm to 1.5mm, and the warm rolling reduction rate is 50%, and make the warm rolled plate air-cooled to room temperature; Intermediate annealing is performed between the warm rolling processes of the passes, the annealing temperature is 800°C, and the time is 10 minutes, and then it is c...

Embodiment 2

[0063] The present embodiment provides a high-strength plastic product medium manganese steel, the preparation method of which is basically the same as that of embodiment 1, and the difference is:

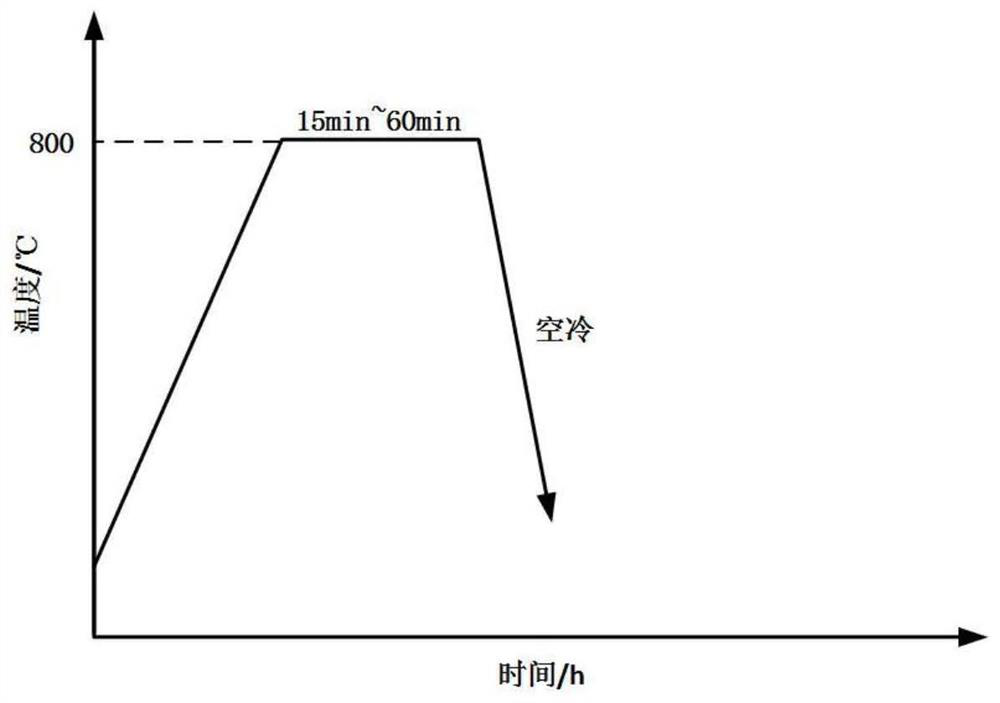

[0064] The warm-rolled sheet obtained after the three-pass warm rolling + annealing process in step 3 was kept at 800 ° C for 15 min, 30 min, and 60 min, respectively. The heat treatment process was as follows: image 3 and then air-cooled to room temperature to make three groups of medium manganese steel sheets with high strength and plastic product.

[0065] The three groups of medium manganese steel sheets were tested for performance, and the results are shown in Table 2:

[0066] Table 2. Performance test results of medium manganese steel sheets

[0067] The holding time of the board tensile strength Elongation after break Strong plastic product Yield Strength 15min 1112.12MPa 76.75% 85.36GPa·% 625.19MPa 30min 1105.62MPa 76.87% 84.99GPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com